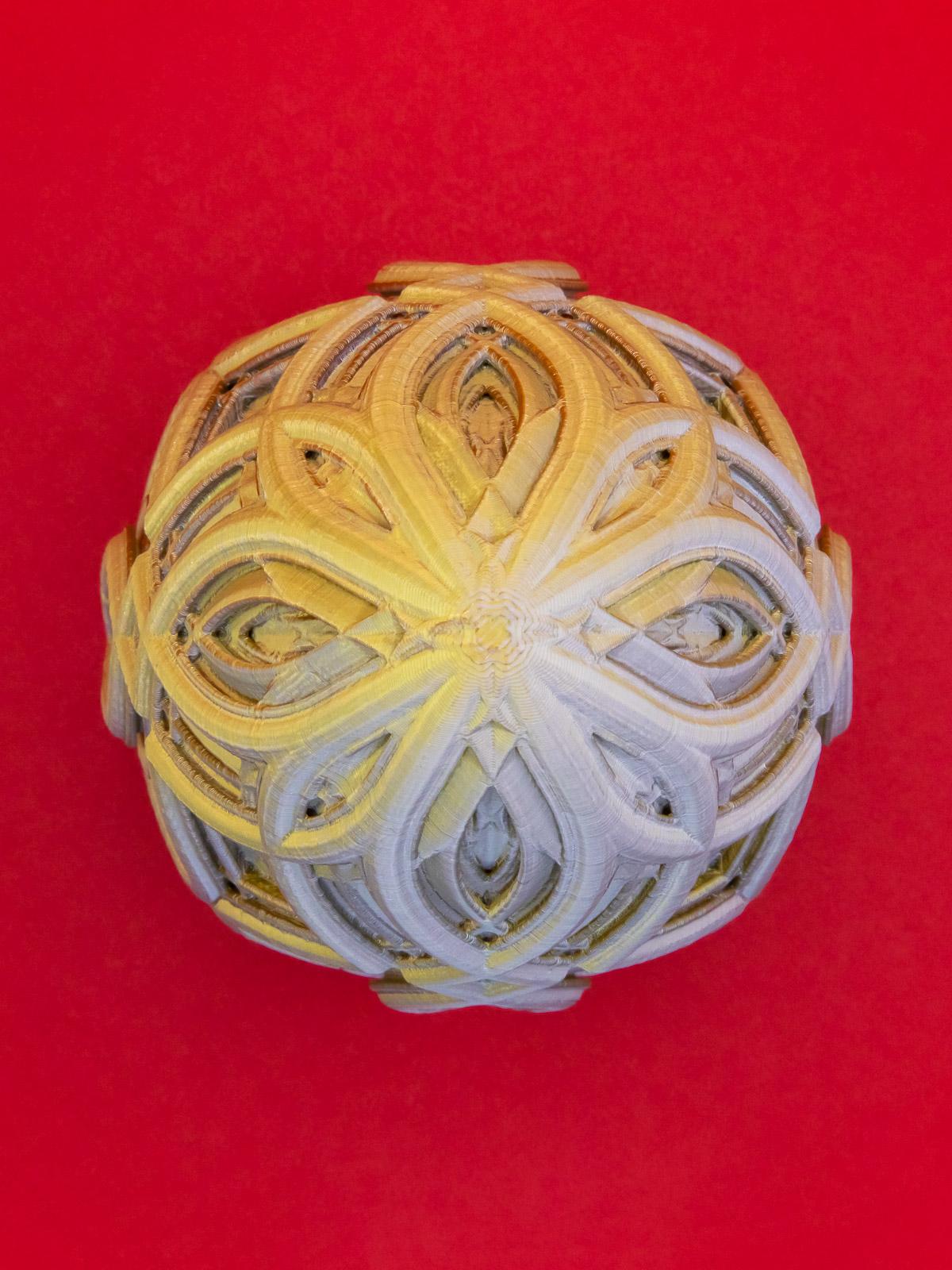

The first of a fun new series of Easter egg with patterns that seem to change as you rotate the egg.

Not for commercial use. Please see license agreement.

This is relatively easy to print. Both pieces can be printed “right side up” so you can use 3-color filament or rainbow filament and have the colors match up. Because of the complex moves the printer has to make, it may need to be printed slower than other models.

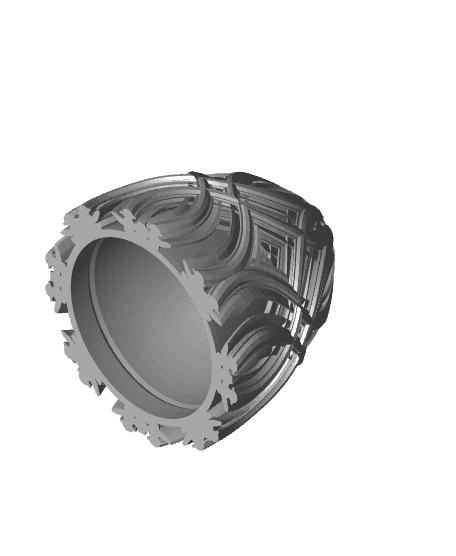

To open the egg, grab both halves, wiggle & pull apart. The bottom half has a slight ridge on 2 sides that clicks into a groove in the top. Because of that, it's easier to separate them wiggling in one direction than another. If wiggling one way doesn't work, try the other. It does get easier to open with use. When the pieces are together, hold one side and twist the other 360 degrees a few times and it will loosen up dramatically. You can also encourage it a little (if necessary) with a little sand paper.

For settings, you can give it 2 perimeters, 15% infill, and default top and bottom thickness. The top prints best with supports for the inner dome (I used paint-on supports) and the bottom works best with a brim or supports for bed adhesion. I used PrusaSlicer's pain-on supports.

To print lighter and save time, you can use the settings I've provided in my PrusaSlicer 3MF files and MKS3+ GCODE. There, I've used layer height adjustments to vary infill and top/bottom thickness to reduce weight and improve print time.

To print eggs that fit inside each other like Matryoshka dolls, I recommend scaling to 100%, 68%, and 46%. If you check my earlier egg designs, they said 70% and 50%. Why the change? Easy. This one is wider on the outside to allow for the more complex patterns. So, it needs to be scaled down slightly more. The inside of this egg is the same size as all my other eggs, so you can more easily resize, mix and match nested eggs. To print below 46%, you may need to use a 0.25mm nozzle.

The tightness of the pieces will vary based on a lot of factors, including scale. If you find the pieces are too tight, you could sand the rim of the bottom piece a little. If that doesn't work, consider reprinting with less flow, lower temperature, more elephant foot compensation, but first make sure you have the printer calibrated so the first layer prints well.