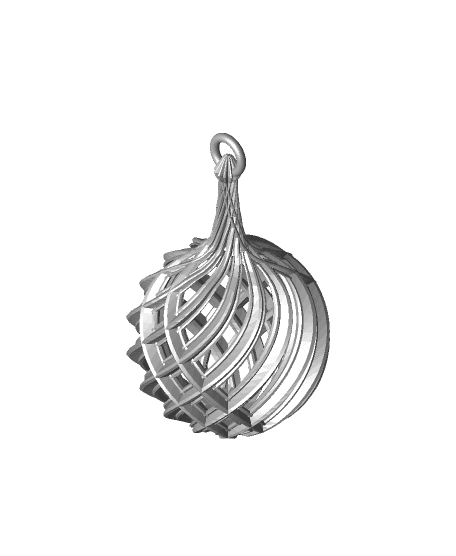

Spiral and Fine Lattice Balls with Stems

These are new variations on my Christmas Balls with Integrated Stems. They're relatively easy to print.

Not for commercial use. Please see license agreement.

RESIZING These should scale up well, but I'm not sure how much smaller you could print them using a consumer FDM printer. Using a resin printer, you could probably print them much smaller.

PRINT TIME About 5 hours each.

PRINT SETTINGS The trickiest parts to print are the tops of the stems. Using FDM, if you don't temp, speed, flow, and cooling right, the thin parts of the stem will melt as you print. Thinner walls help. If that's not enough, try increasing the layer height.

Thickness

- Layer thickness: .15 mm

- Wall thickness: 0.4 – 0.8 mm (I printed 0.4 mm and checked “alternate extra wall” so it alternated between 0.4 and 0.4 mm walls with each layer)

Infill I would use 100% infill for the first 2mm. After that, infill doesn't improve print quality.

Speed

- Outer Wall: 35 mm/sec

- Inner Wall: 40 mm/sec

- Travel Speed: 60 mm/sec

Build Plate Adhesion I used a brim. With the supports, you shouldn't need a raft.

Supports You will probably need supports for both bed adhesion and the overhang on the first few layers. You shouldn't need supports for the loop at the top. Adding them would just increase the chances the supports broke and caused the print to fail. So, I used a support blocker to ensure the only supports were below the balls.

- Support Structure: Tree

- Support Placement: Touching Buildplate

- Support Overhang Angle: 57 Degrees

For the spiral ornament, I added custom supports for the arms that receive the least support from the counter-rotating arms. You may not need it the extra supports. In case you do, I've included a screenshot of my set-up and support settings in Cura.