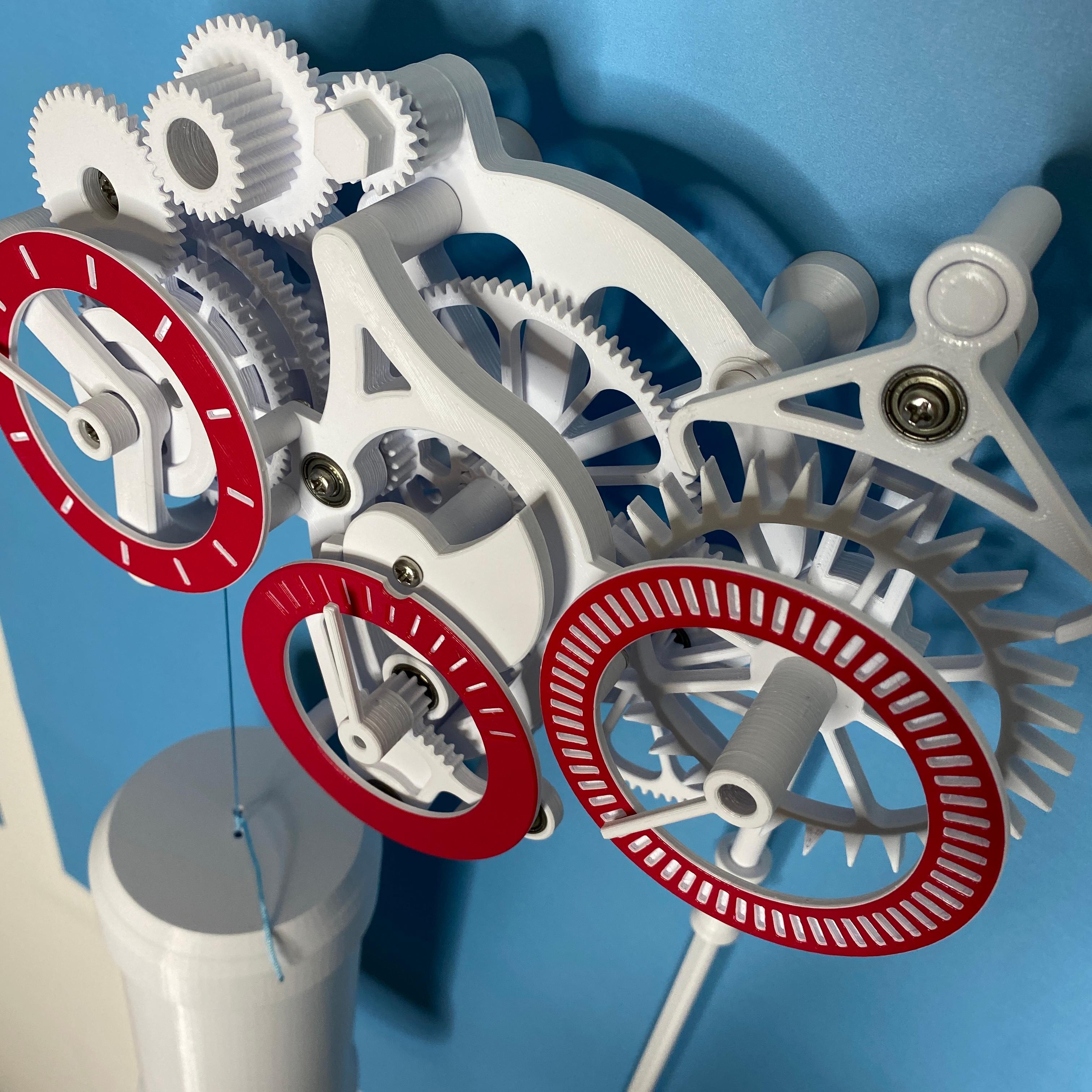

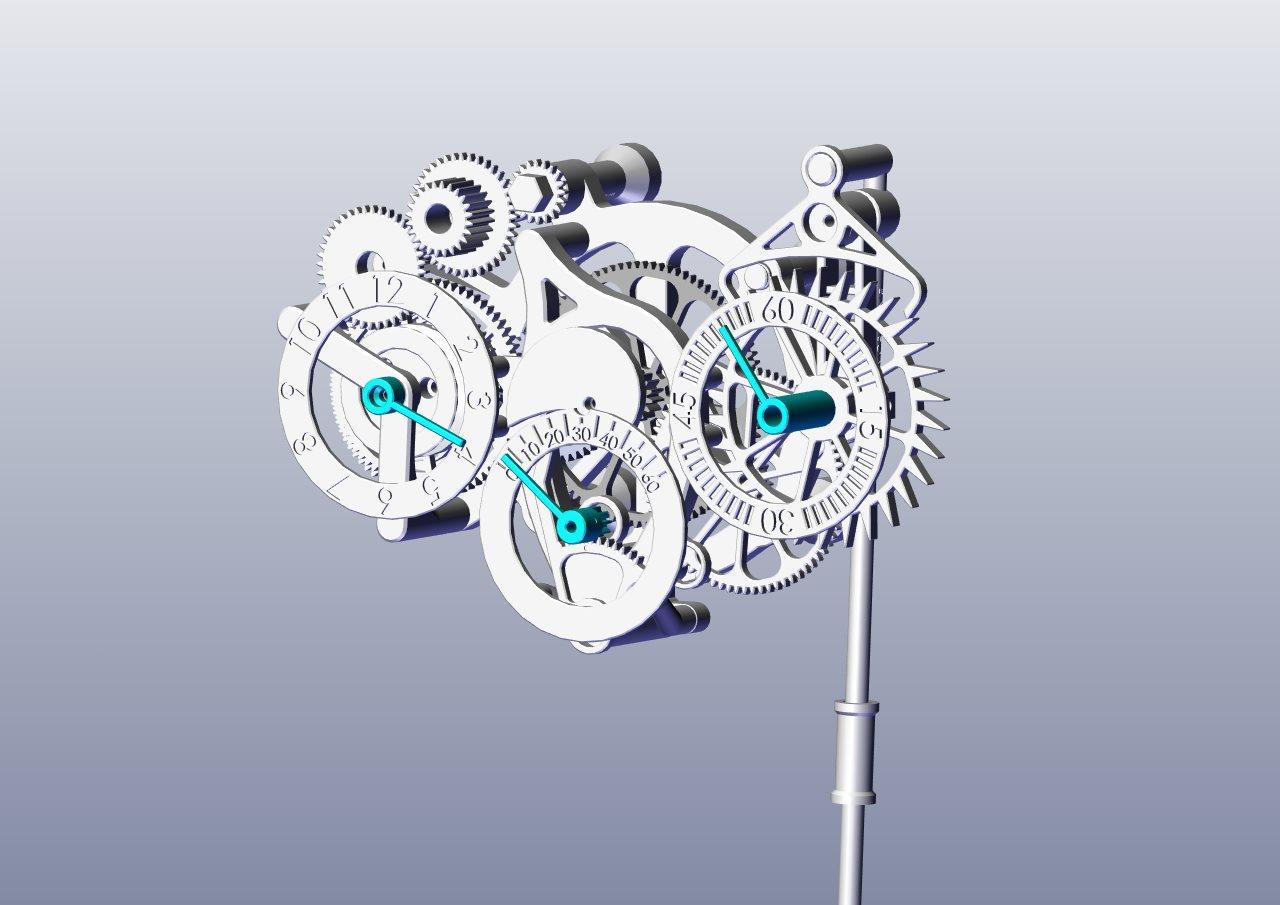

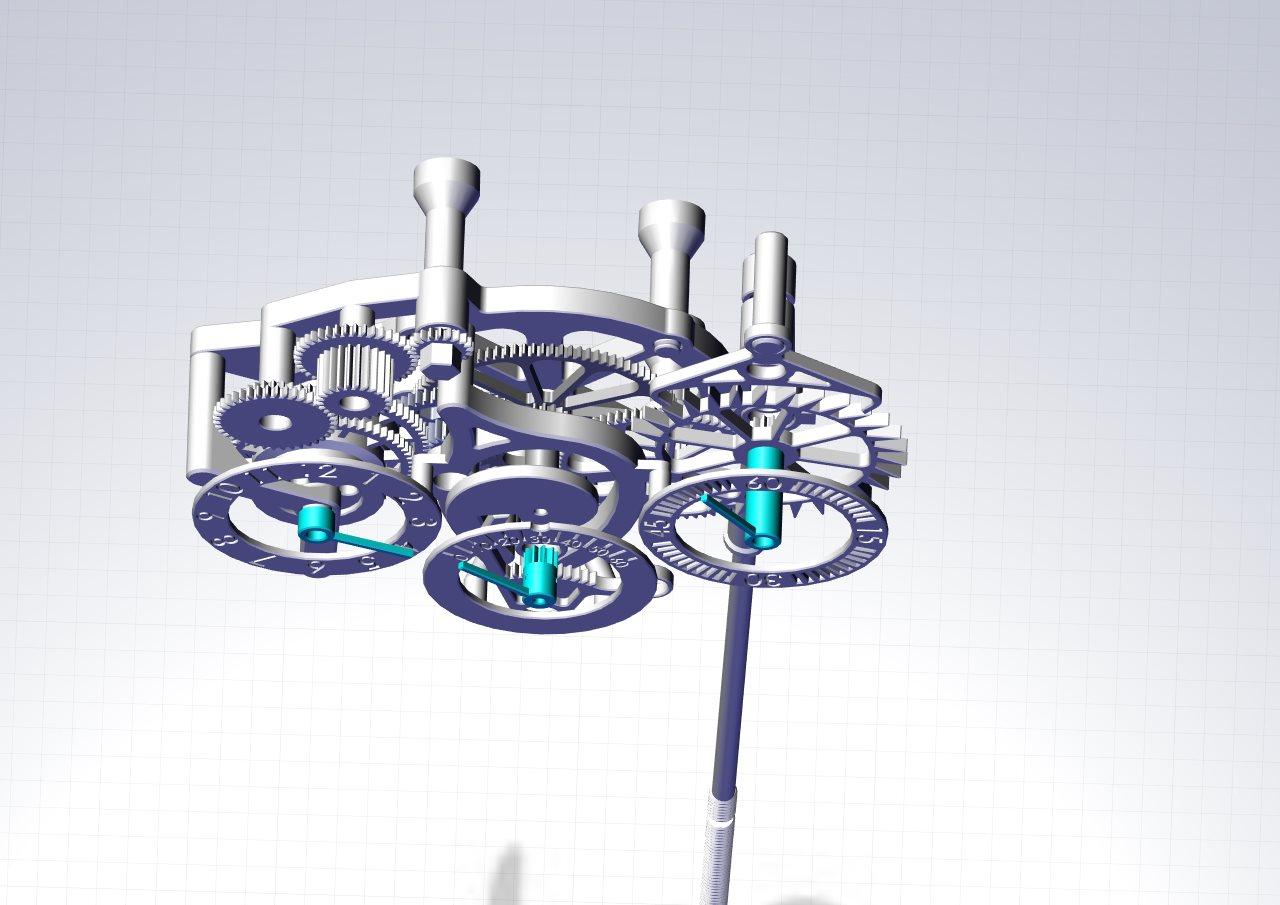

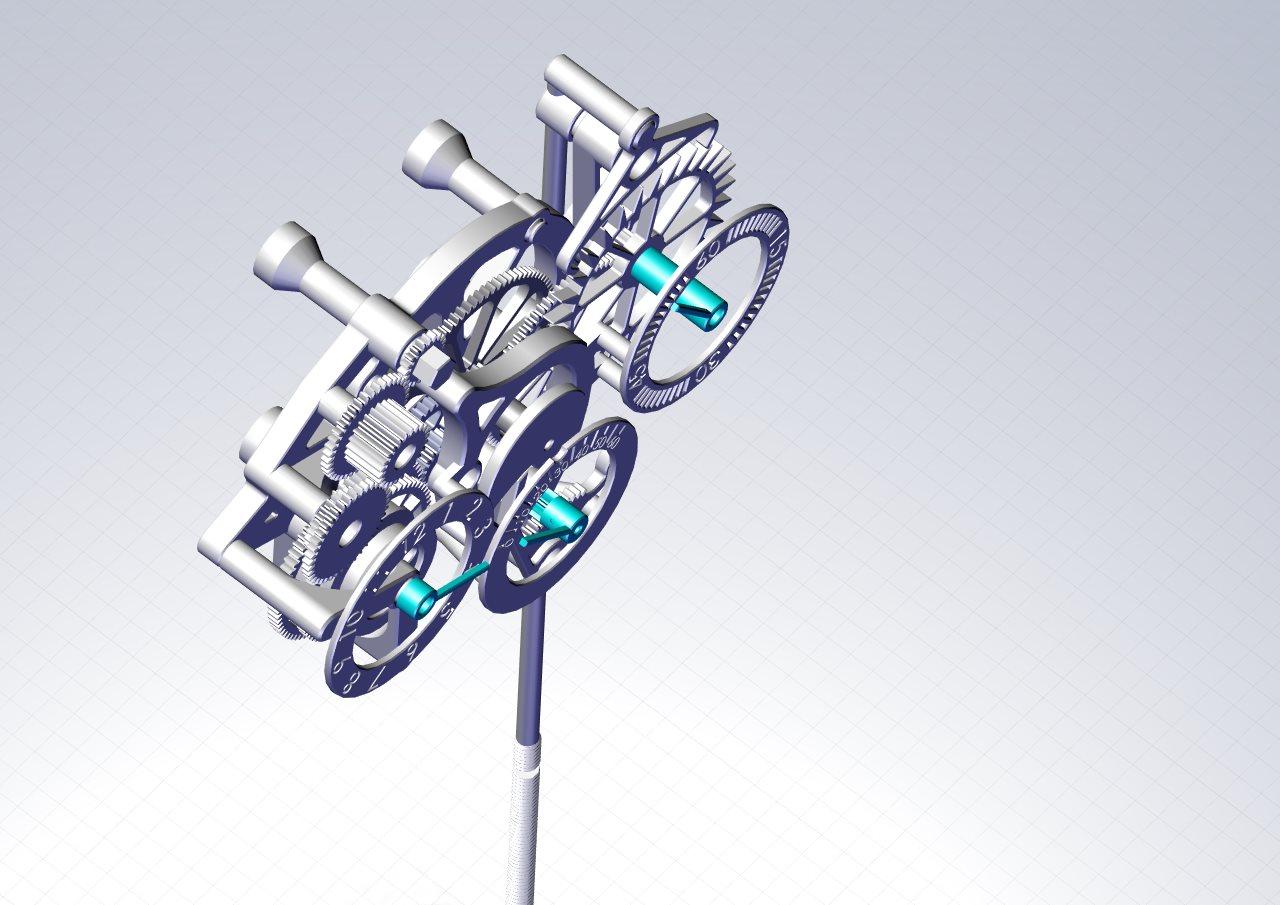

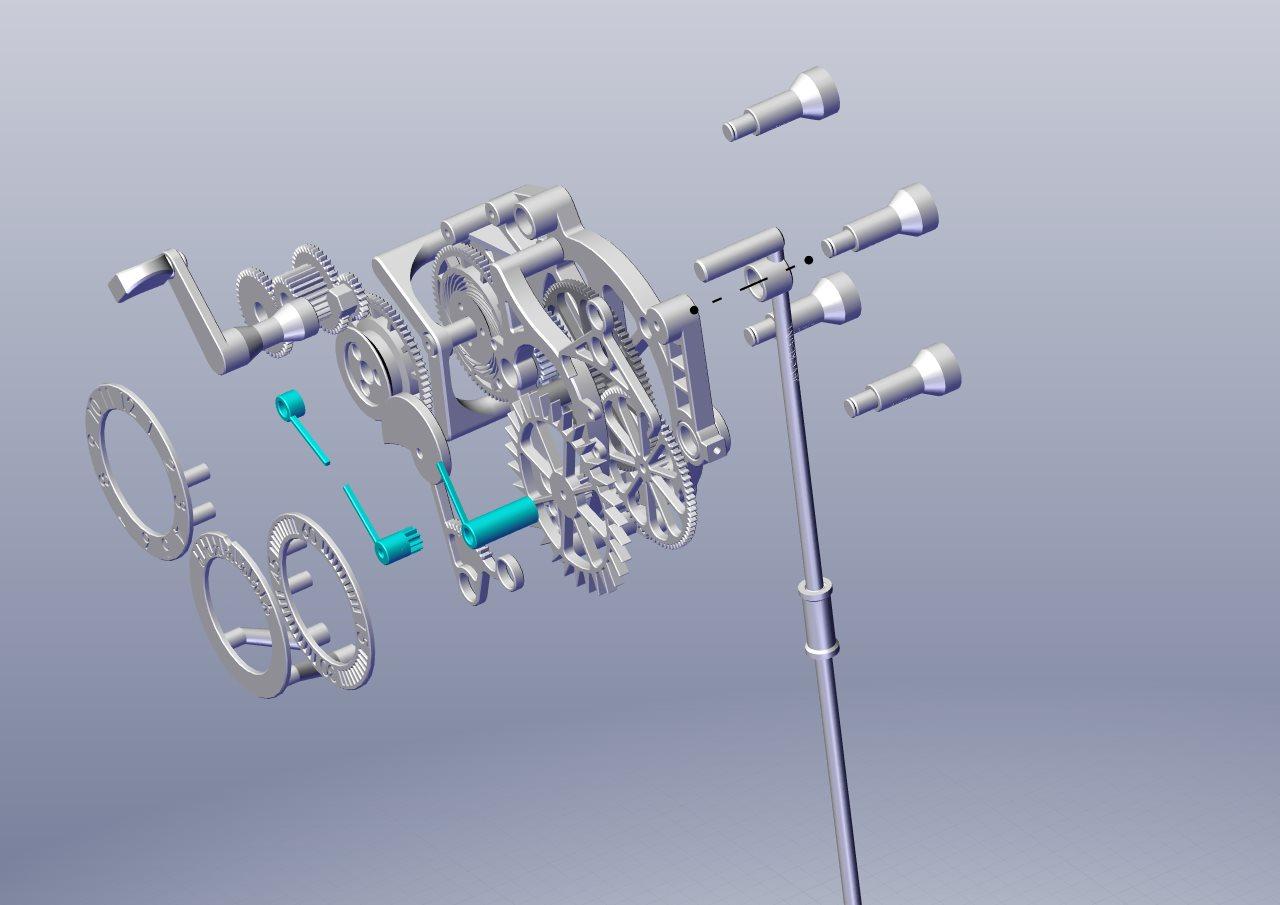

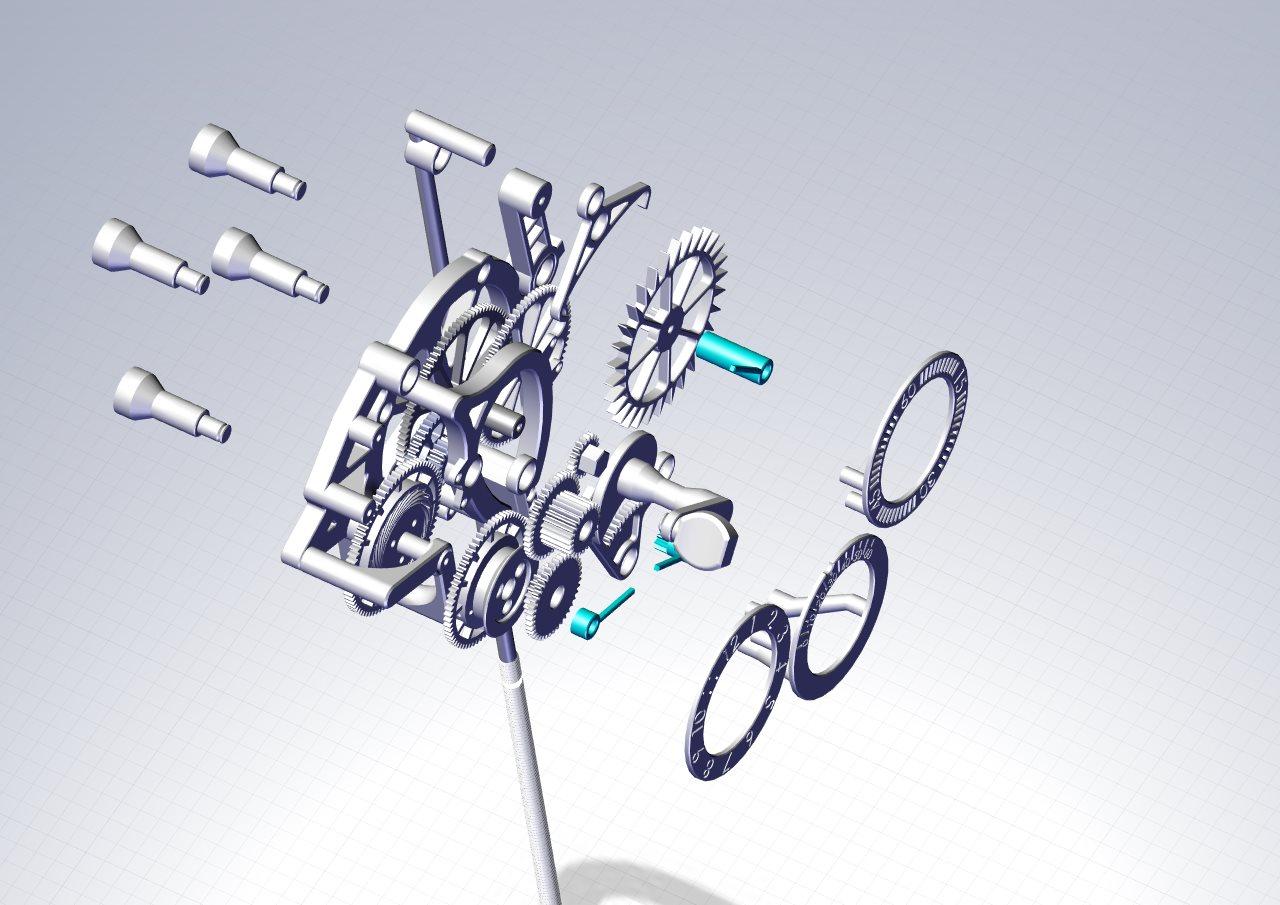

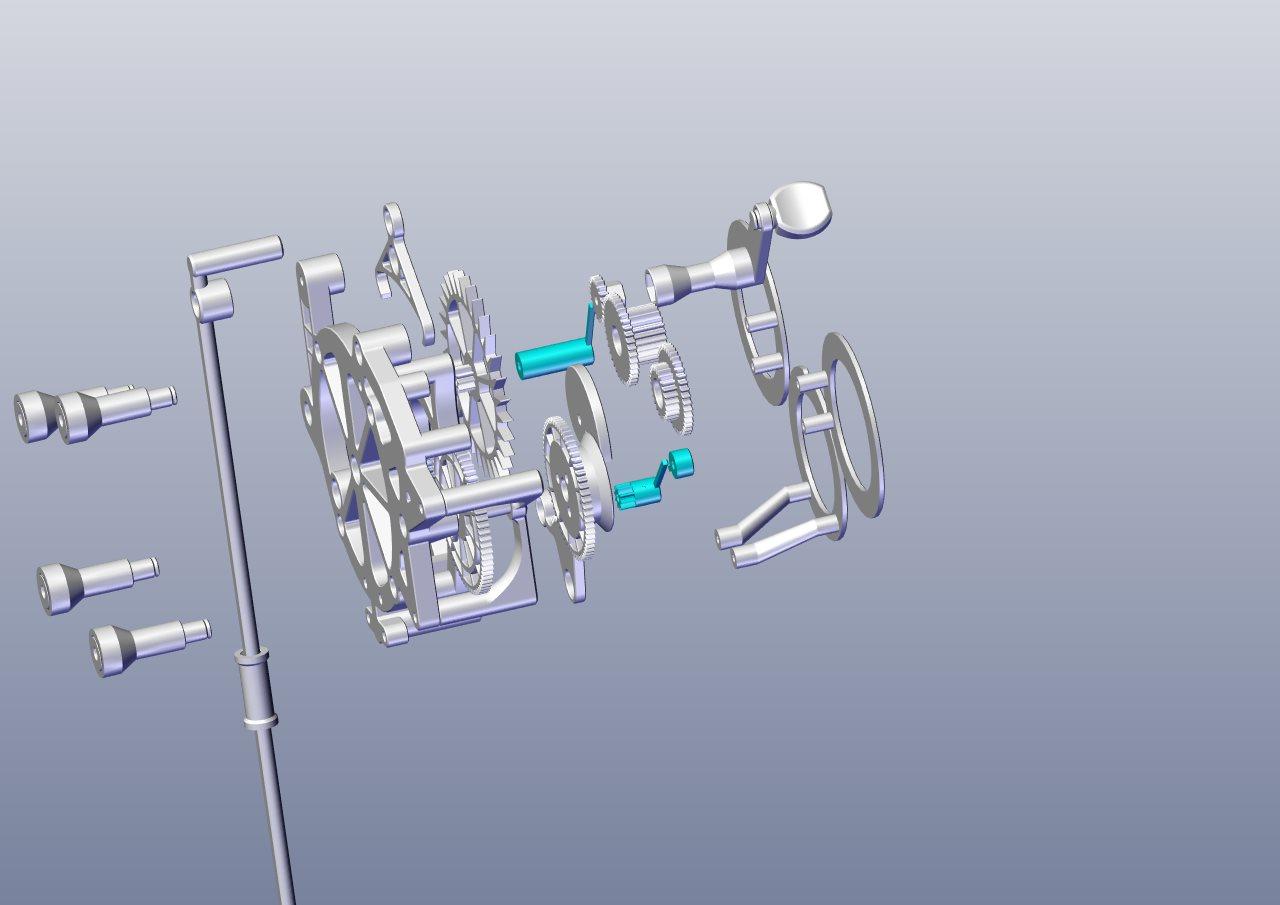

This is a fully functioning 3D printed grandfather clock. Using mainly 3D printed parts, this clock was specifically engineered to be assembled in minutes, and can run for over 6 days on a single winding. With a little bit of tuning, it can accurate keep time with that classic tick-tock sound.

The video below shows how easily this clock can be assembled

The STL File:

Prints on all standard 3d printers without supports, requires the following additional parts to assemble:

- 21 M4x12| 11 M4x20 Screws (https://amzn.to/3zgQb8f)

- 23 M4 Washers (https://amzn.to/3E1crFU)

- 17 624Z 13mm OD/4mm ID Bearings (Like these https://amzn.to/3DtUUpH)

- 1mm Nylon String or Fishing Line (I used string from this set https://amzn.to/3DtUUpH)

- 5 pounds of weight - could be ball bearings or a dumbbell (I used one from this set https://amzn.to/3zfVKUy)

Recommended print settings:

Layer Height: 0.2mm Nozzle: 0.4mm Infill: 15-20% Material Required: ~650g (Printed in PLA) Minimum Build Plate Required: 180x180mm

**All the files have been pre-oriented to save you some set up time! All you need to do is drop the parts into your slicer and hit print!

.png&w=3840&q=75)