3D Printer filament can be degraded by moisture, some plastics more so than others, hence controlling moisture levels will improve the filament quality and, as a result, lead to better print quality, too.

I house each of my filament rolls in an individual dry box. I maintain the moisture levels by including a box of desiccant inside the dry box. I also monitor the moisture level with an in-built hygrometer.

Filament impacted by moisture exhibits the following characteristics, brittle "like spaghetti" (PLA), increased stringing (eg. PETG) and "bubbling" (eg. Nylon, TPU) to name just a few.

The individual dry box approach allows me to customise the degree to which I can maintain the individual reel moisture levels. My Nylon filament is kept at a level of less than 15% humidity whilst PETG is maintained at less than 20% humidity.

To control moisture at different levels means having different amounts of included desiccant in each filament dry box. So, to that end I have different size desiccant boxes to meet my varying desiccant amount needs. Including more desiccant also means less frequent need to dry out the desiccant.

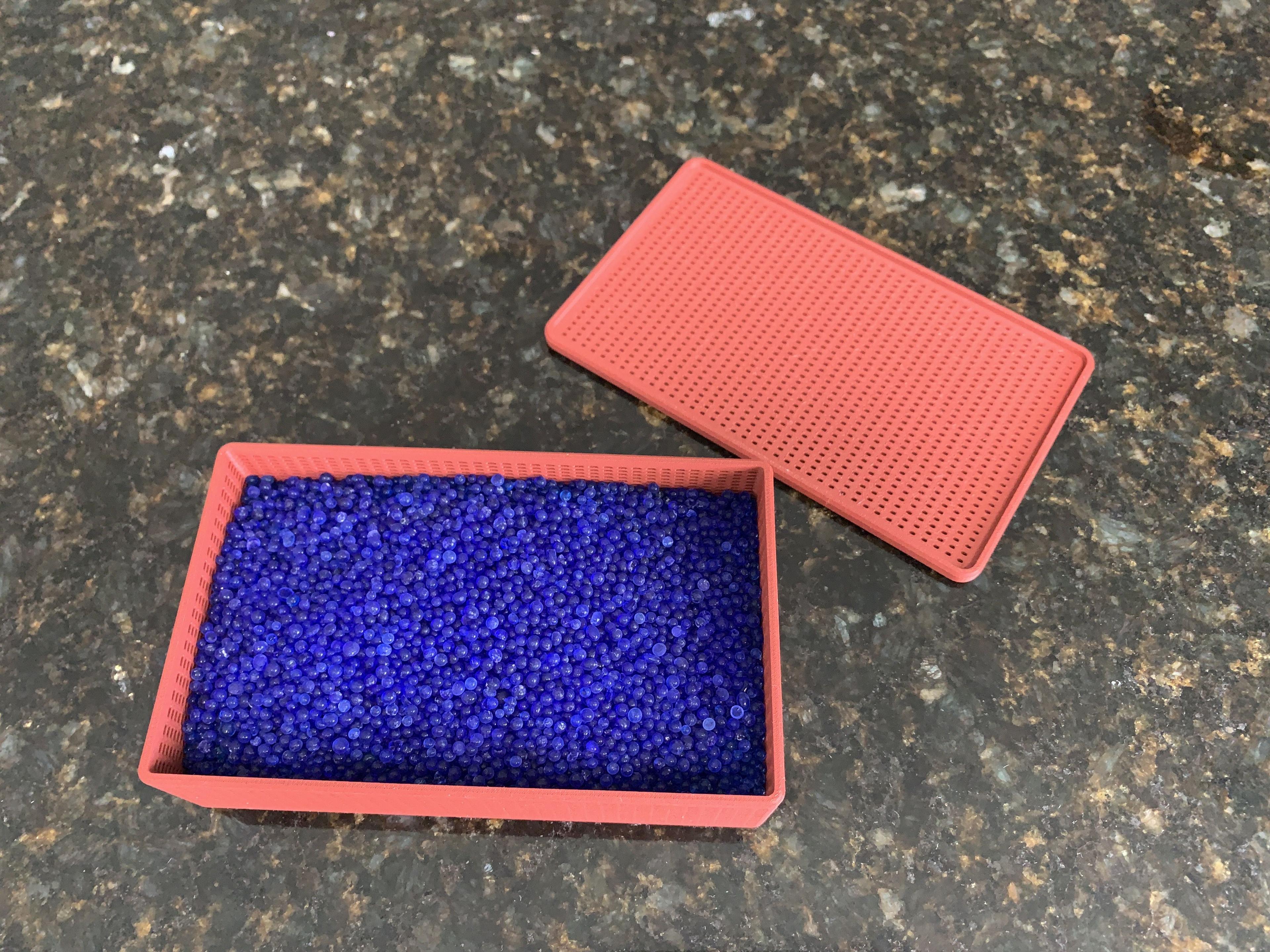

I designed custom boxes to enclose the desiccant with lots of small holes for air circulation. The box size is 190 x 60mm with a press fit lid. The box come in two sizes, 20 and 30mm high (outside dimensions). The boxes hold about 125g and 300g of Silica Gel, respectively.

Over time, the Silica Gel will need refreshing and drying out. Follow manufacturer guidelines on the drying process. Note, heat Silica Gel outside of the 3D printed box.

The 3D printed box lid nicely friction fits onto the box. The risk of the box accidently being knocked open is low, but should it happen, that's a lot of desiccant pieces to get scattered, retrieve and clean up, so I place a rubber band around the filled box.

NOTES

-

There are factors that will affect duplicating my results. These factors include your environment, effective dry box seals, quality of Silica Gel. If unsure, the simple rule is more Silica Gel the better.

-

This approach to keeping filament dry is effective for filament that is already dry. Desiccant alone will not remove moisture that has already been absorbed by the filament. A filament drying process not covered here is required.

-

There are alternatives to Silica Gel to remove moisture from the air that can be effective, too. These alternatives are more or less effective, relative to Silica Gel, hence the quantity placed in this box will need adjusting, accordingly.

Here is my 3D design. My design may match your needs, too.

My print is made in 1.75mm Bambu Lab Burgundy Red PLA-CF filament, with 0.2mm layer height and 15% infill on a Bambu X1 Carbon printer.

I hope that you can find this print useful, too.

Remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.