Worried about your bank cards being scanned? Keep your wallet in your back pocket? Want a smaller, slimmer, rugged alternative to a normal wallet? Loose your wallet a lot?

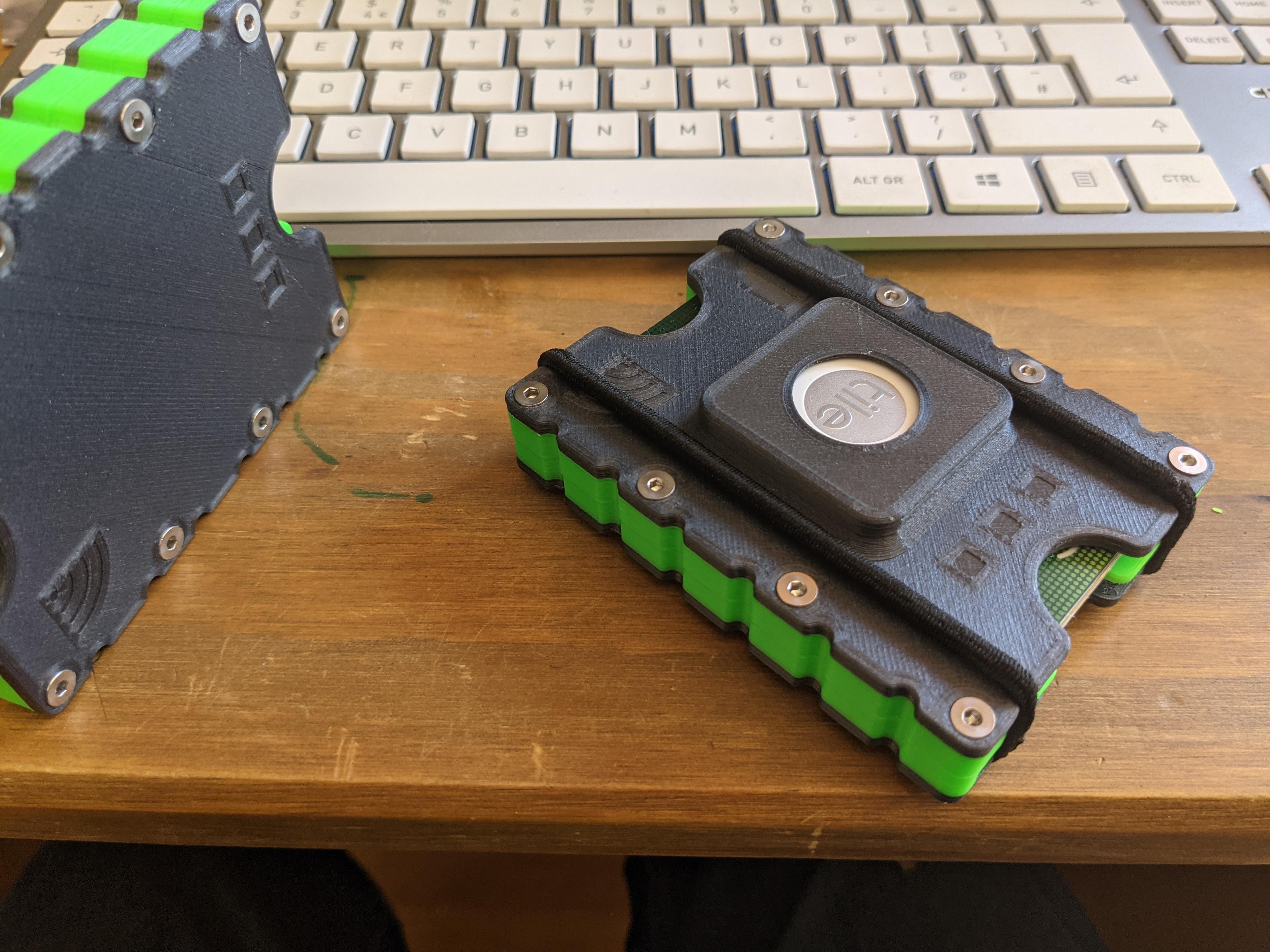

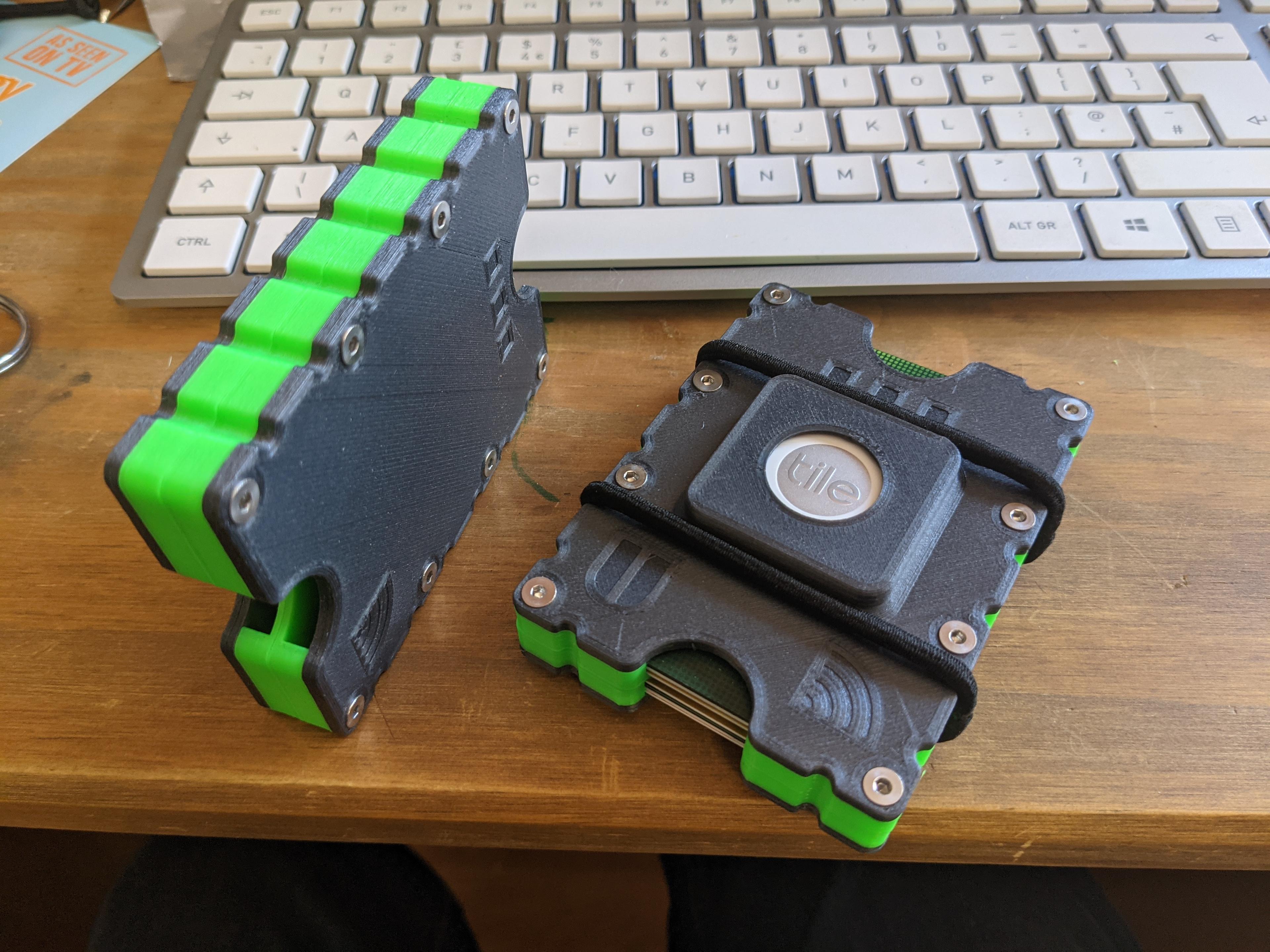

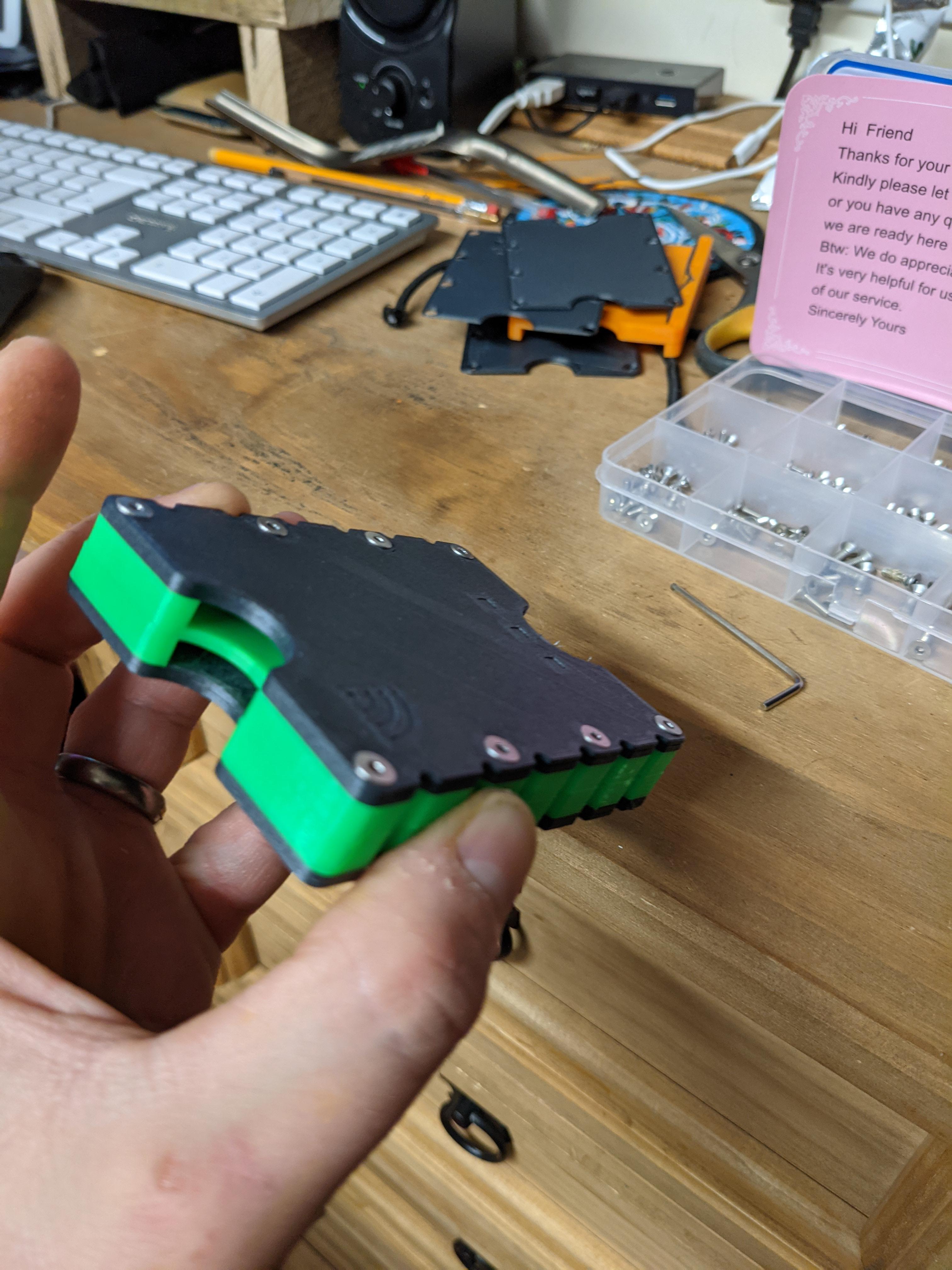

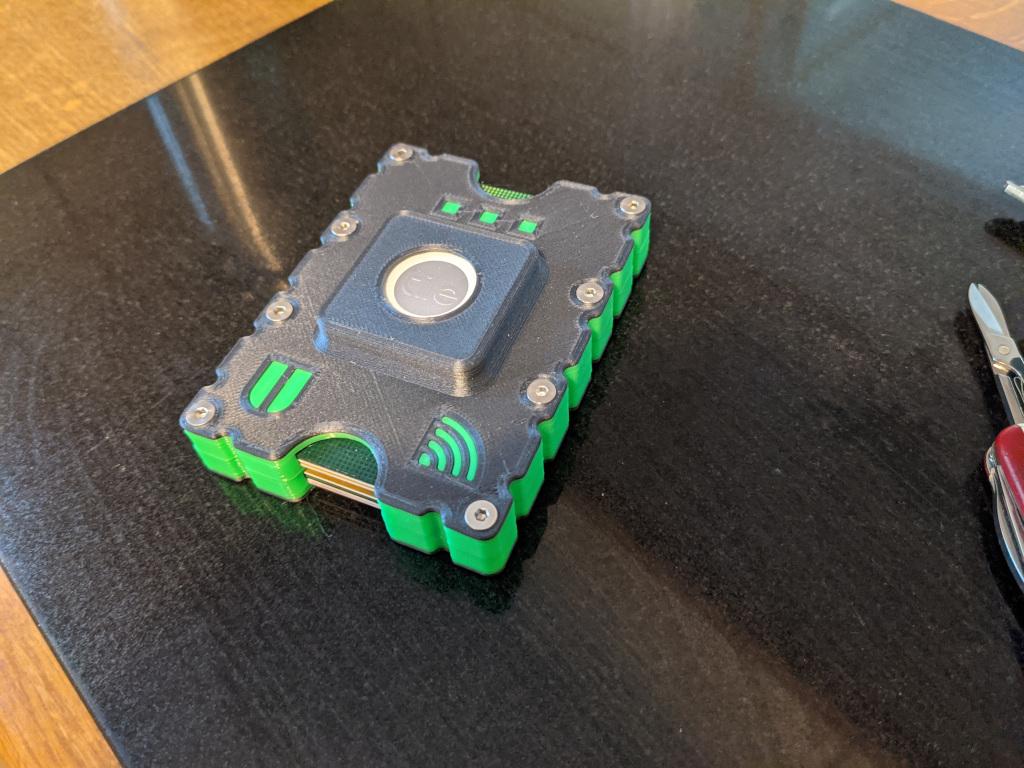

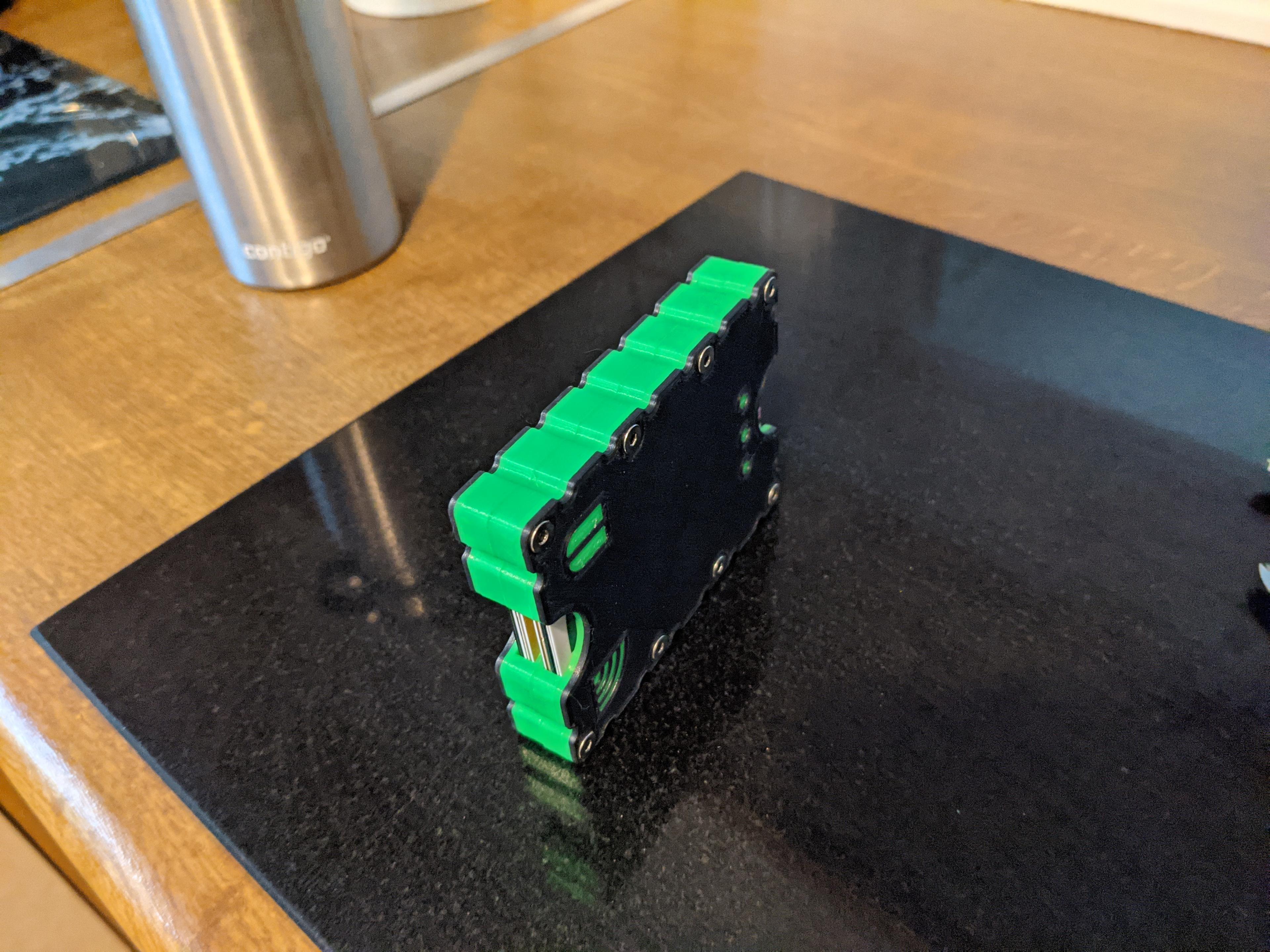

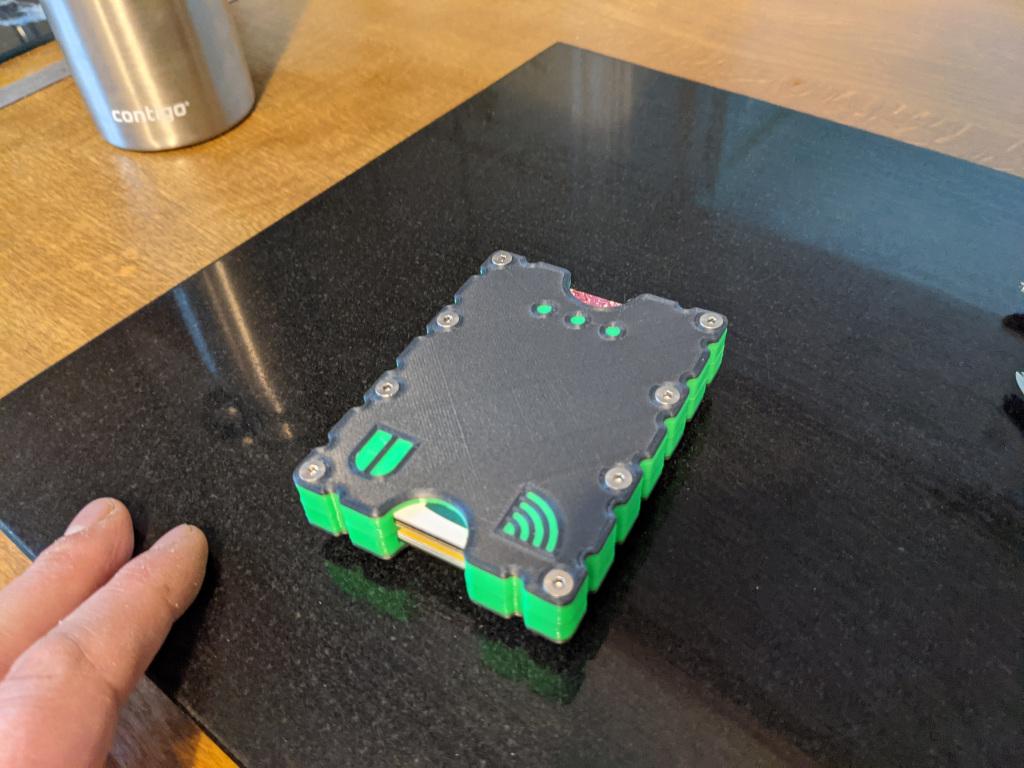

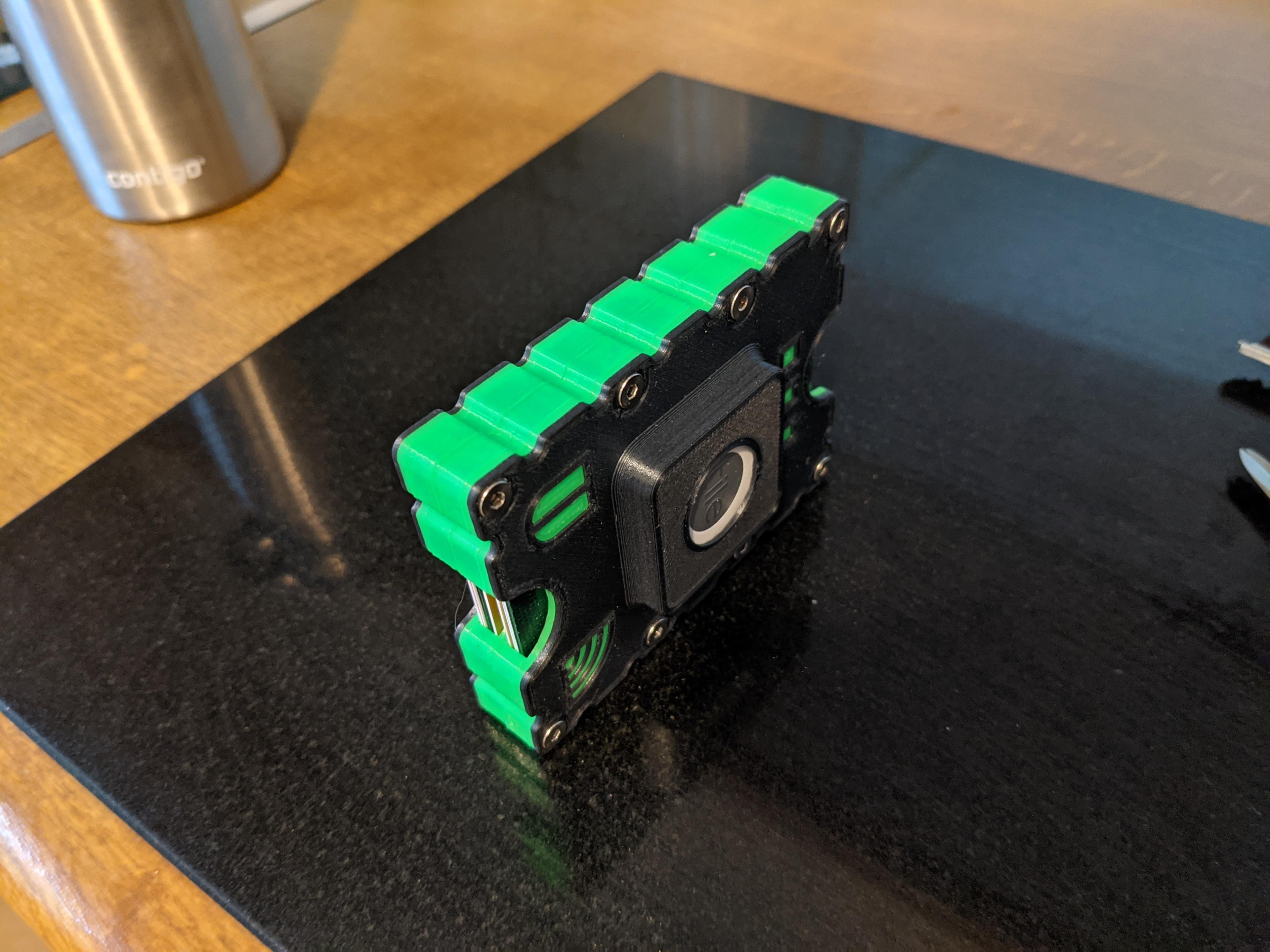

The RF contactless shielding wallet, protects up to 8 full sized bank cards at once from RF scanning using a thin layer of aluminium foil between top and bottom. With the optional hair bubbles for money clips and tile plate, you can securely place a tile tracker in your wallet too, to help you find it.

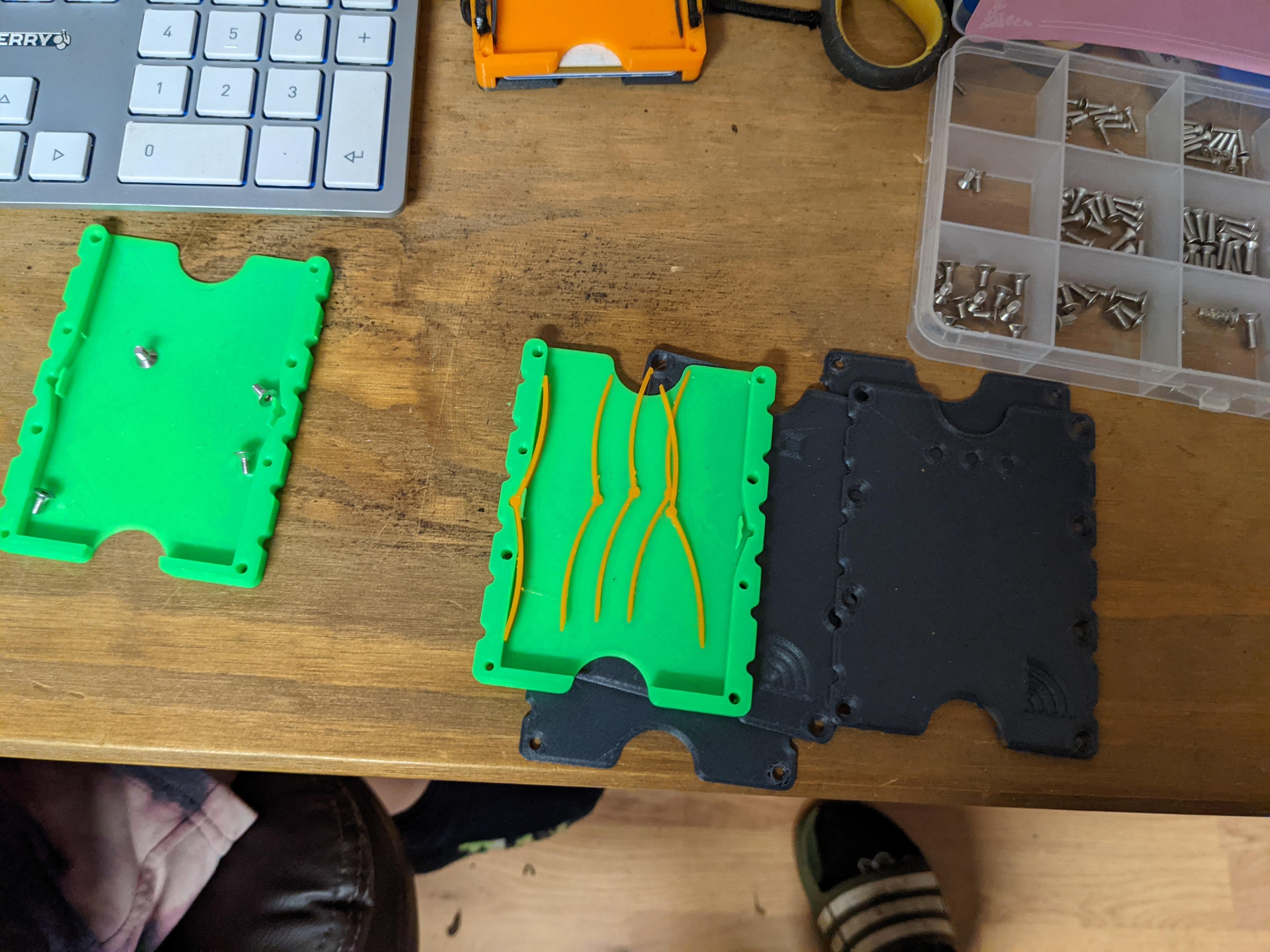

With internal springs to keep cards in place, notches all round for easy grip, or maybe you want to wrap a hair bubble around the wallet in the grooves to use as a money clip, this nifty wallet allows you to keep your cards safe and secure.

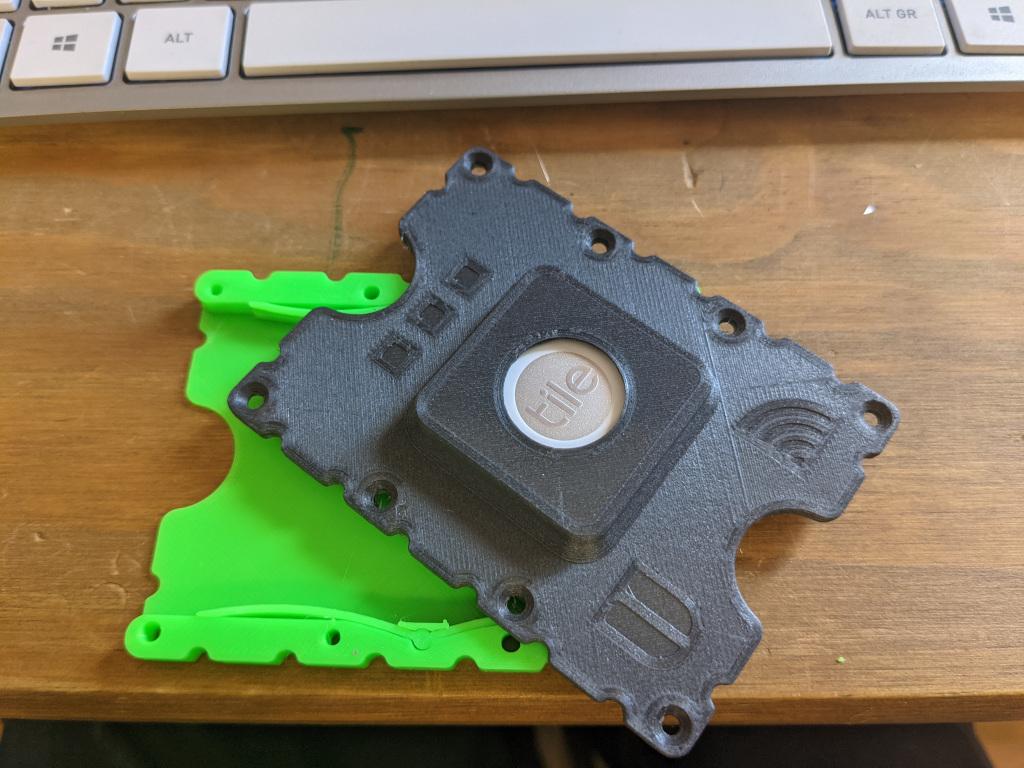

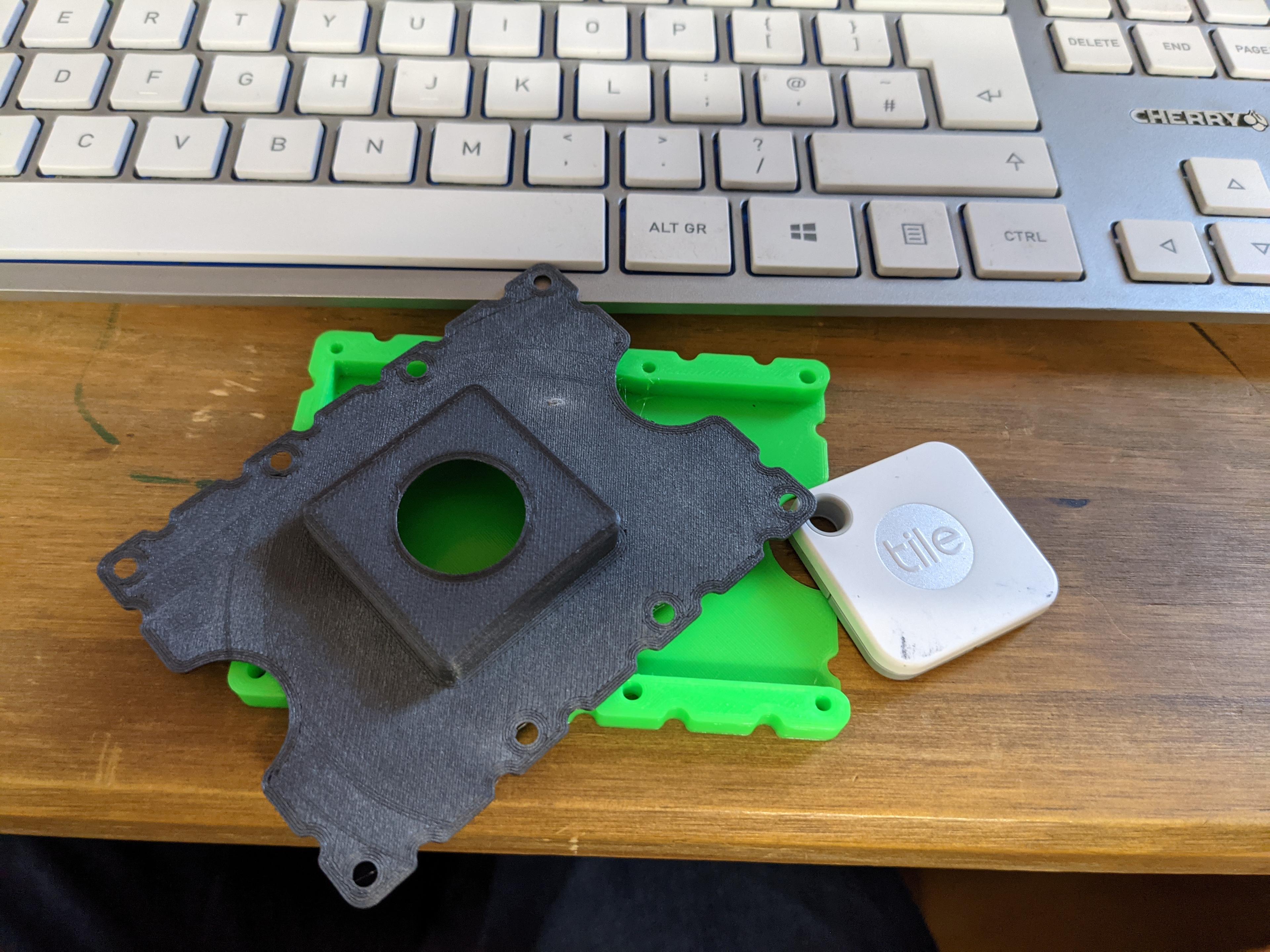

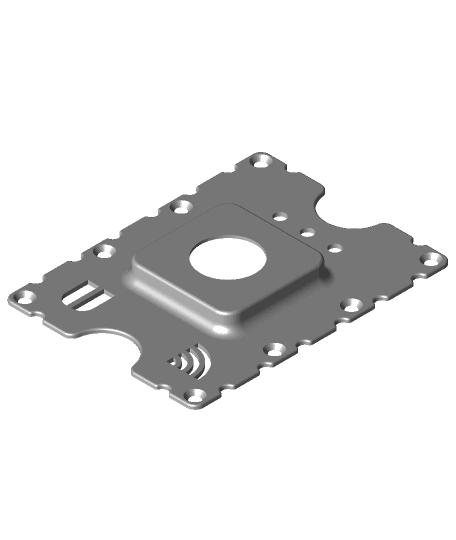

Comes with branded plates, clean plates and tile recessed plates for options.

Requires: 8 off 3mm D (M3) x 6mm H countersunk screws 8 off 3mm D (M3) x 12mm H countersunk screws Optional 2 off small hair bubble in grooves as money/receipt clip Optional 1 off Tile Tracker for finding your wallet (use tile plate stl)

Parts: https://www.amazon.co.uk/gp/product/B0819QXRBR/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

https://www.amazon.co.uk/nuoshen-Elastic-Bobbles-Ponytail-Elastics/dp/B099R4VVS3

https://www.amazon.co.uk/Tile-Mate-Item-Finder-Pack/dp/B07W9BBCTB

Filament: PLA Green - https://www.amazon.co.uk/SUNLU-Filament-Tangle-Free-Dimensional-Accuracy/dp/B07TPS5P87

Carbon Fibre - https://www.amazon.co.uk/ZIRO-Printer-Filament-Carbon-1-75mm/dp/B01IICFS4Y

Printing: I use PLA internally for holder and springs, carbon fibre for plates. Printing with 04 nozzle at standard quality. Speeds are not an issue, go for 30% ish infill.

Tile plate requires support such as tree touching build plate at 60 or more overhang

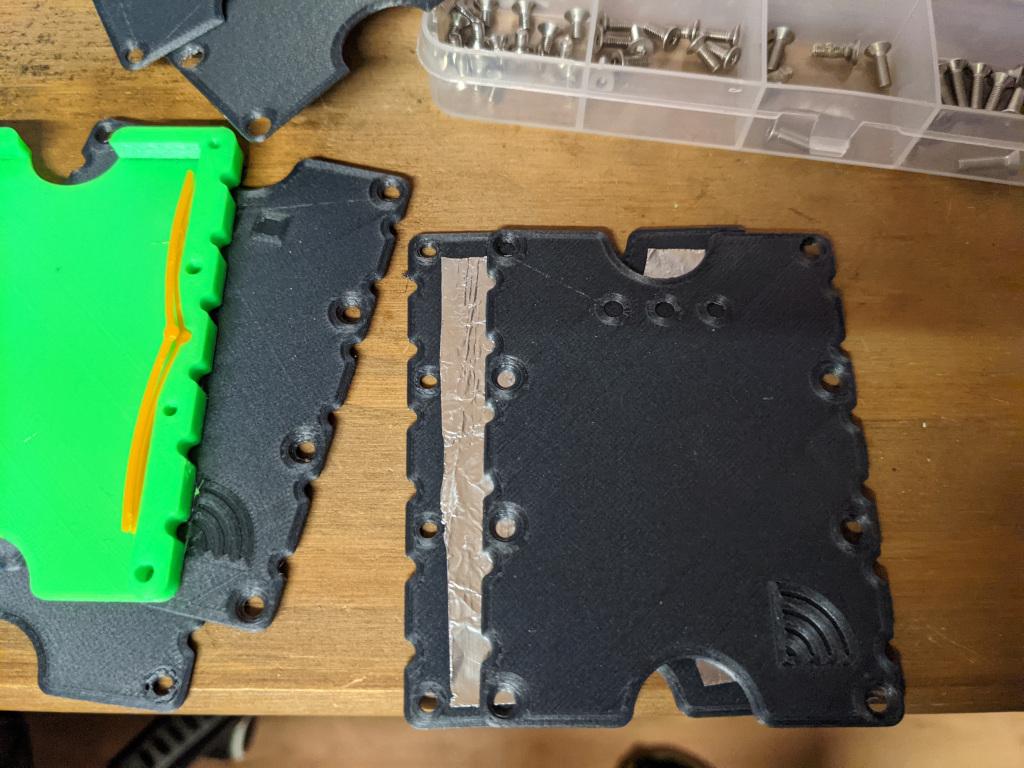

Assembly: Easy, 4 off 6mm H and 4 off 12mm H M3 screws for each side (once springs in place), Some holes screw, some go through to screw to the holder behind. So 4 screws hold plates, 4 hold plates and screw to holder behind.

Don't forget to sandwich aluminium foil between lower and higher plates to shield (tested on various machines).

3D PRINTING SETTINGS I use PLA internally for holder and springs, carbon fibre for plates. Printing with 04 nozzle at standard quality. Speeds are not an issue, go for 30% ish infill.

Tile plate requires support such as tree touching build plate at 60 or more overhang