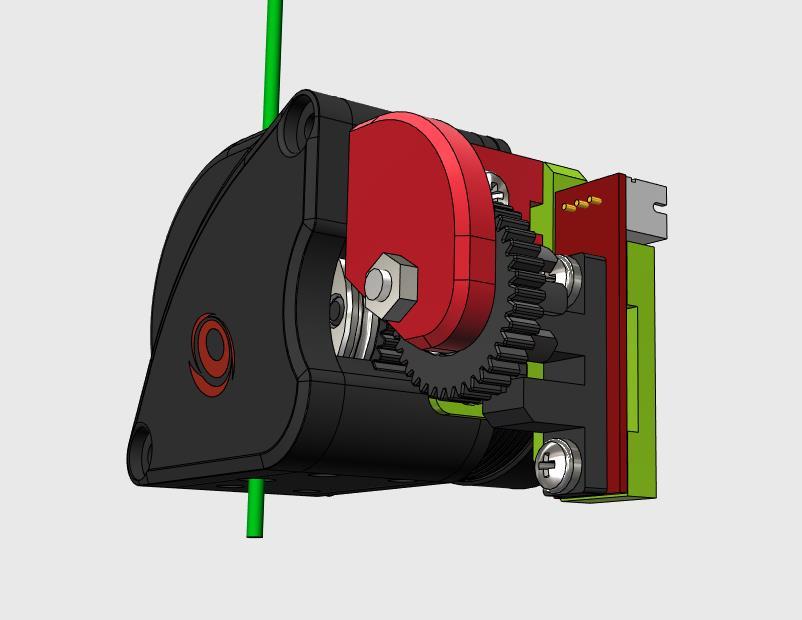

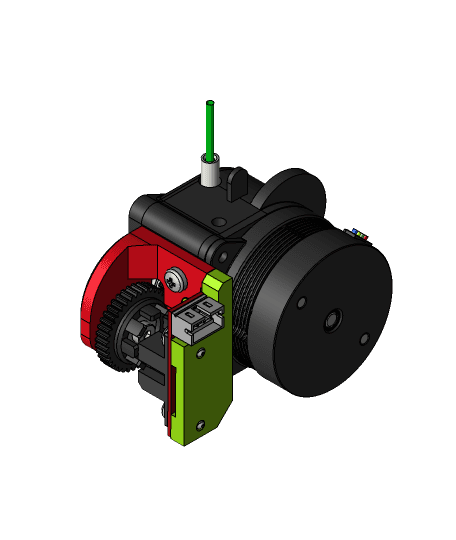

Filament-Encoder for LGX-Lite Extruder

I made this tool as a proof of concept. I was looking for a different method for the 2nd endstop on the Filament-Cutter for LGX-Lite Extruder, since the usual method (adding a switch to the tension lever) does not cut here.

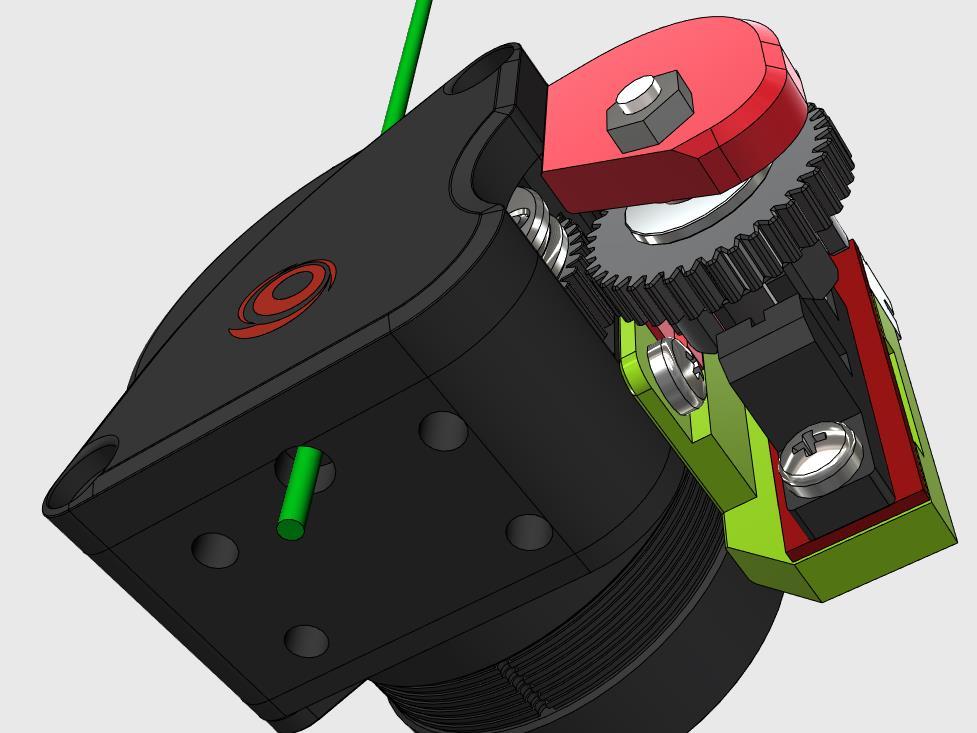

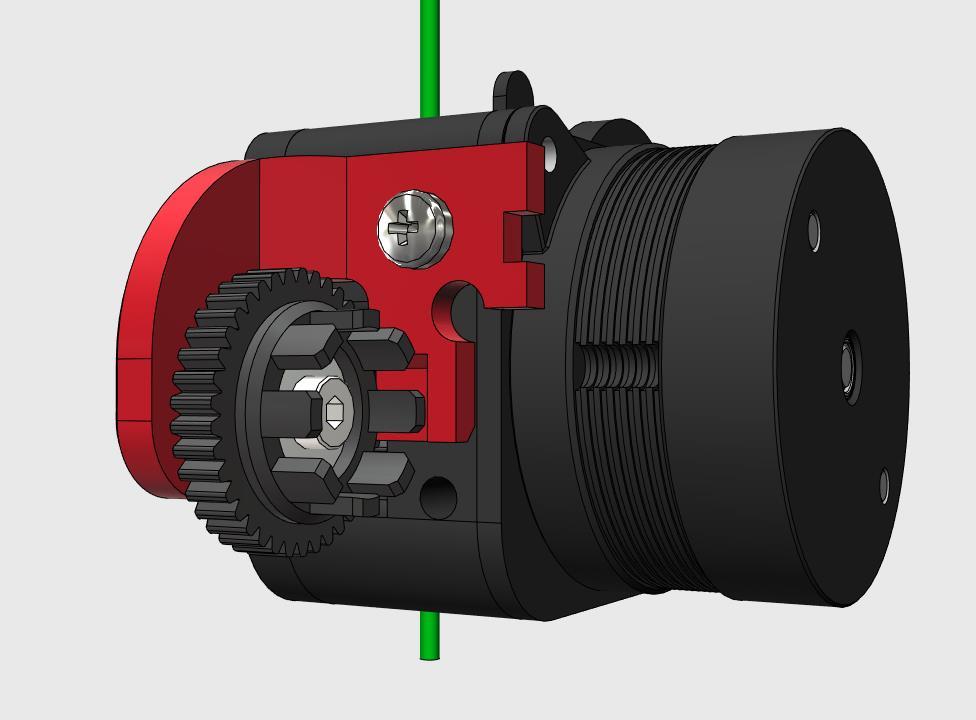

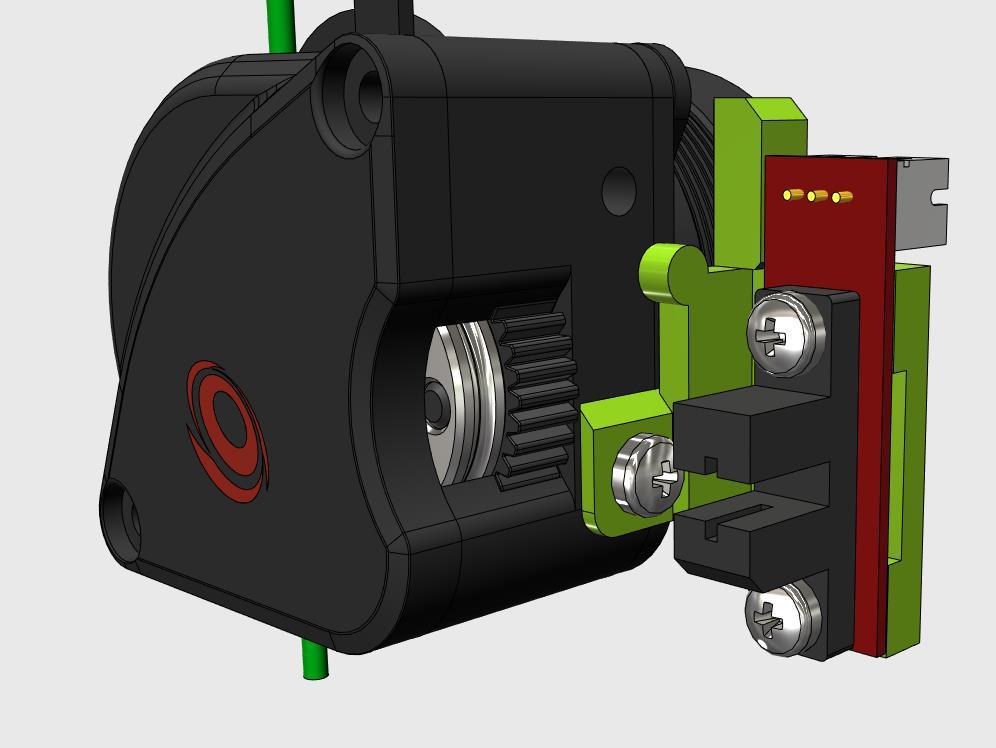

So I decided to go with an optical sensor, which gets triggered by an encoder/flag wheel that is driven by one of the dual drive gears. This is the result and I quickly realized, it can also be used as an filament motion sensor. I'm not using any filament motions sensors yet but I though it could be fun publishing it.

So, if you plan adding such an encoder to your extruder, feel free to give it a try and let me know the results.

Please keep in mind: I haven't tested this gadget on a real LGX-Lite and there might be an issue with the gear I've modeled. However the STEP file is included, so you can easily make some quick & dirty adjustments if needed.

Beside a couple of screws for mounting the optical sensor and the encoder itself to the LGX-Lite, you'll also need a flange bearing of type F623ZZ (ID: 3mm OD: 10mm height: 4mm), a M3 x16 bolt and a M3 (self locking) nut.

The encoder mount is split up into two parts for easier mounting. Attach the Encoder-Sensor-Mount part to the LGX-Lite first and bolt it down, then screw on the optical sensor. After that mount the Encoder-Gear-Mount (with the Encoder-Gear already mounted) and bolt that one down as well.

Here's a short video showing the device in action using a simple geared motor.

For using this gadget in Marlin, you'd have to recompile the firmware with these options enabled:

_#define FILAMENT_RUNOUT_DISTANCE_MM #define FILAMENT_MOTION_SENSOR _ For Klipper you'd need these settings:

__[filament_motion_sensor lgx_lite_encoder] detection_length: len extruder: extruder switch_pin: pin runout_gcode: FILAMENT_RUNOUT __

Make sure you modify the detection_length and switch_pin accordingly.

Credits Special credits go to Mad Hatman for the LGX-Lite model he has published on Grabcad. I had to make some modifications though, since the gears were not modeled very detailed (but I think that's mostly because it's based on the original Bondtech STEP file).