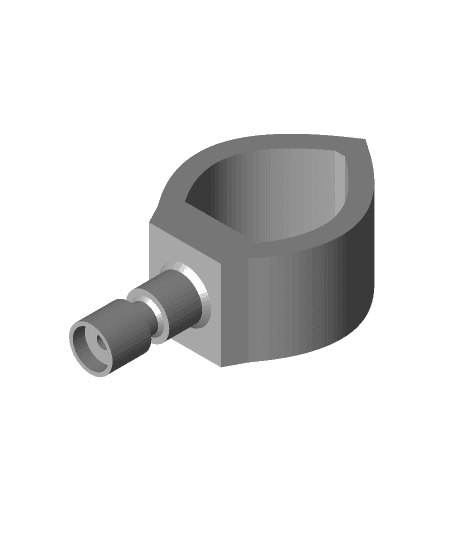

Old style Bombard oar holder (rare design paddle holder, not produced anymore)

byprintableconcreteDesign by http://www.fiberprinting.com/ - Rendering by http://www.fiberprinting.com/integral-molding/ - Photographs taken on site at http://www.budapest.homes/

Old style paddle holder for older Bombard inflatable dinghy boat. This is a drop in replacement for the older style Bombard oar holder, but is designed to be much stronger. The original piece is injection molded and only around 1,5 mm thick. This replacement part is 6 mm tick and has an integrated M4 stainless bolt in the stem for added strength, as the part is prone to split at the stem and the ring shaped section.

Part list: 1 piece of stainless steel M4 bolt with hexagonal head, 40 mm long threaded section and 43 mm length over all 2 pieces of washers with an outside diameter of 11.5 mm 1 piece of M4 nut

Printing It is best to use a more tougher material as PLA as this part is structural and is subject to great loads while paddling. A good choice would be PETG or tough PLA. Nylon would be great as well but could be a challenge to print as the part requires support under the stem. 100% concentric infill, a high flow multiplier ratio and high temperatures paired with slower printing will make the part stronger.

Post processing Remove the support, file blobs, insert the M4 bolt with washers and a nut, and tighten the nut.