Backstory I frequently use my Bora Edge Clamp to cut plywood on the floor while suspended on a 3/4" thick sheet of foam insulation board. However, the clamp's handle is too long to pivot into the proper position to firmly hold the edge clamp against the workpiece because it runs into the floor.

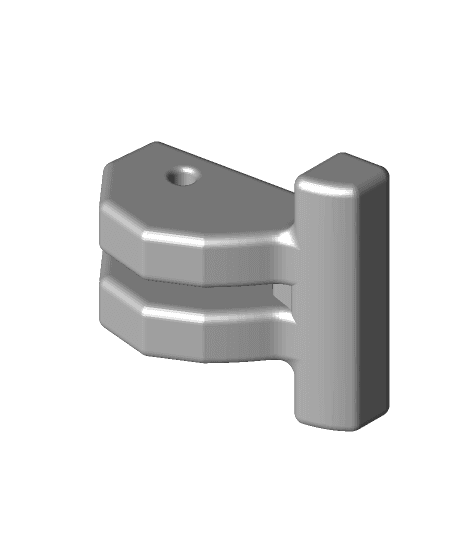

Sizes This replacement clamp handle will pivot fully vertical to apply the proper clamping pressure.

Pin Hole Diameter Tweaking Since every printer isn't the same, I'd suggest printing some hole fitment test jigs so the metal pin fits snugly then use the supplied Fusion 360 files to adjust the handle's hole. The steel pin is .155 inches in diameter. I settled on 0.166 inch for the hold diameter for my use case.

Clamp Handle Disassembly To remove the pin, first engage the clamp handle fully. Use a pair of locking pliers to hold the rod from retracting at the opposite end of the clamp. Remove pin with nail and hammer, supporting where necessary. Replace handle and hammer pin into position carefully.

More Info Thingiverse Thing #4858267