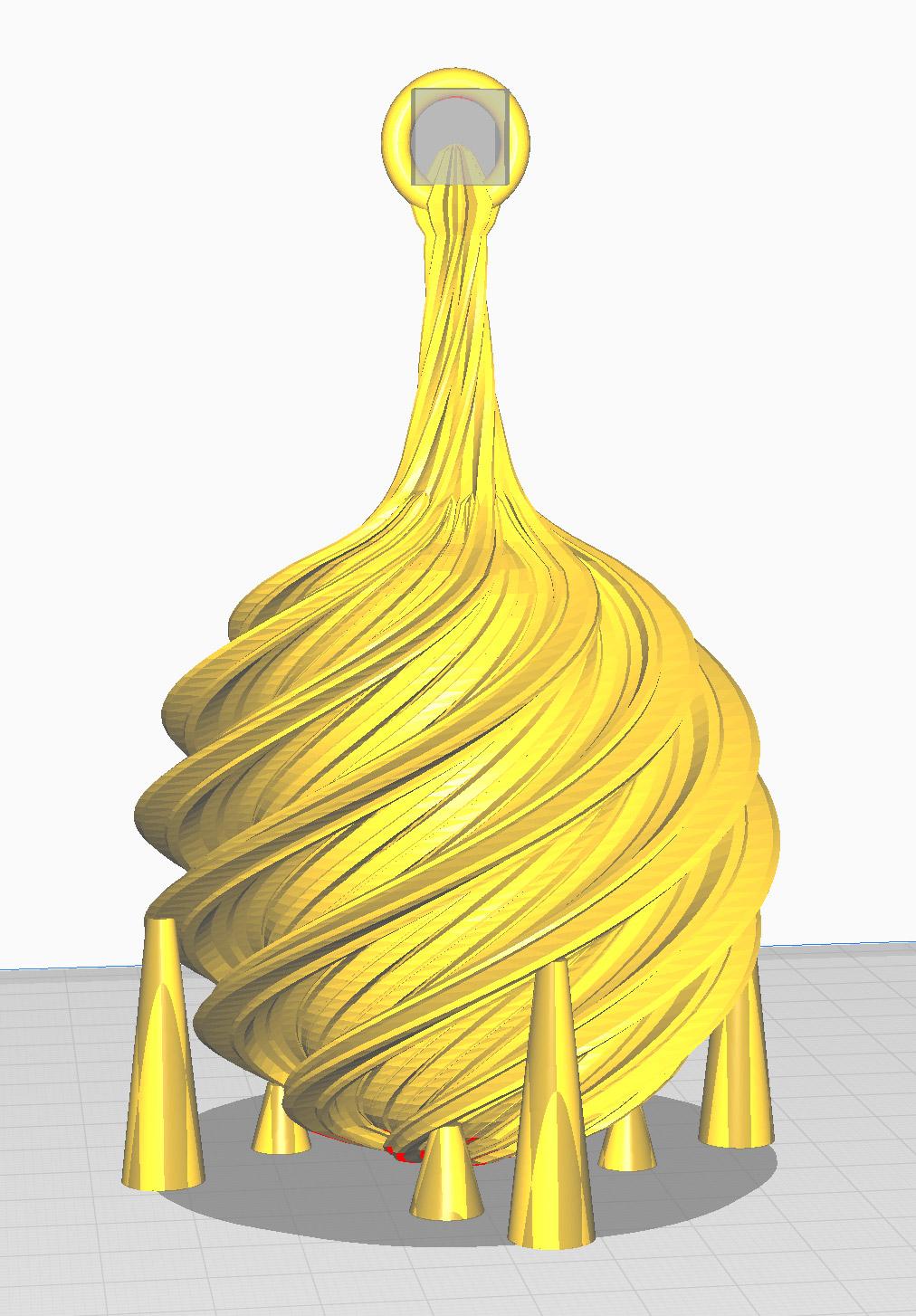

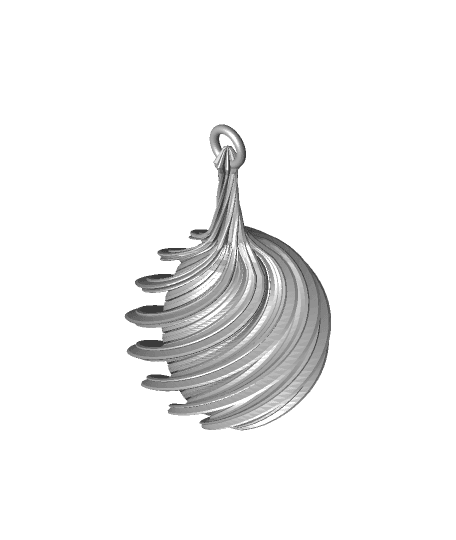

Closed Spiral Christmas Ornament

This is a new variation on my Christmas Balls with Integrated Stems.

Not for commercial use. Please see license agreement.

RESIZING These should scale up well, but I'm not sure how much smaller you could print them using a consumer FDM printer. Using a resin printer, you could probably print them much smaller.

PRINT TIME About 4 hours.

PRINT SETTINGS The trickiest parts to print is the top of the stems. Using FDM, if you don't temp, speed, flow, and cooling right, the thin parts of the stem will melt as you print. Thinner walls help. If that's not enough, try increasing the layer height. I printed at 200 C with 115% flow.

Thickness

- Layer thickness: .15 mm

- Wall thickness: 0.4 mm.

Infill This does not need any infill. JUST DON'T DO IT – especialy if you print it with transparent filament.

Speed

- Outer Wall: 20 mm/sec

- Top/Bottom Speed: 20 mm/sec

- Travel Speed: 50 mm/sec

Build Plate Adhesion I relied on the supports for build plate adhesion.

Supports I first printed with used normal supports and an overhang angle of 67 degrees and no other supports. It worked until 2 minutes from completion, when the model came loose from the bed. When I tried again, I with an overhang angle of 64 degrees and added 8 custom supports that keep the model from wobbling. I've included a screenshot from Cura of the supports.

I added a support blocker in the loop to keep from having supports added inside the loop.