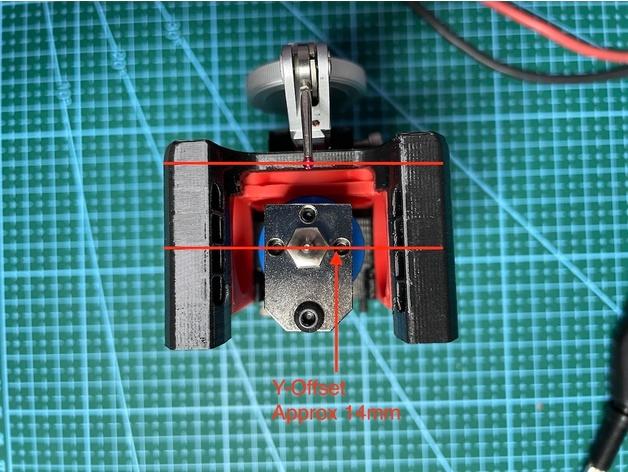

The idea here was to get as close to the nozzle as possible, in this case it is roughly 14mm Y offset from the nozzle.

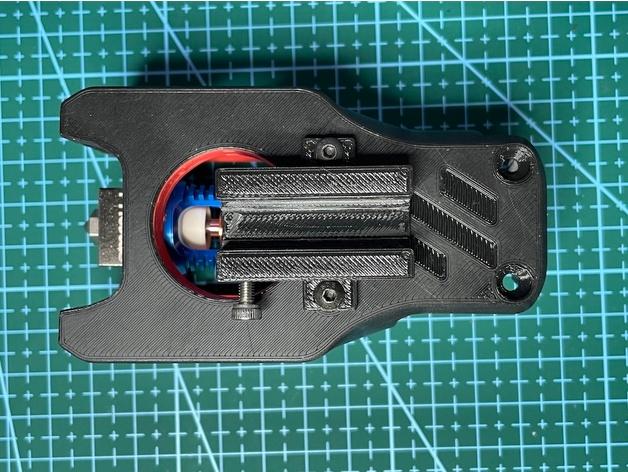

I used the m3 grub screws with nylon inserts (see the image) to prevent scratching the body of the dial indicator, although in the main picture a cap head M3 screw is shown.

The indicator 'mitre' joint might be a bit tight initially, you need to slide it up and down until it moves smoothly.

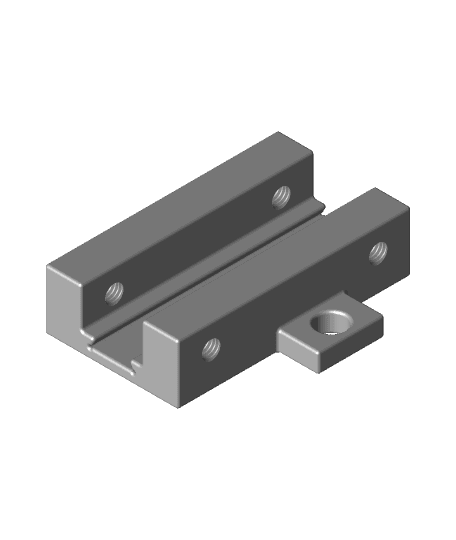

After mounting it to the head with 2x M3 x 40 screws, you can adjust the angle of the probe and slide up/down to adjust the height so that it's just below the nozzle height.

I then created 1/2 dozen macros to move to the bed-screws position using the Y 14mm offset, I have not tested yet but probably the BED_SCREWS_ADJUST can be used by modifying the coordinates to allow for the 14mm Y offset.

It worked great for me, I was able to get pretty much zero error at the 3 points, however the magnetic bed is not flat and it would also be possible to do a manual bed mesh using this setup, but I have not got around to that yet.

Please let me know any suggestions or comments.

Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:4949659.