Easy fix to an annoying problem. Somehow the printer has a 310x310 bed and the X and Y limit switches line up to the edges of the bed.

We cannot utilize the full 300x300 bed size if 0,0 is at the edge of the bed. This is a failure of the written firmware to effectively utilize the 5mm border meant to provision bed alignment variance. I am trying to avoid going down the firmware rabbit hole for now.

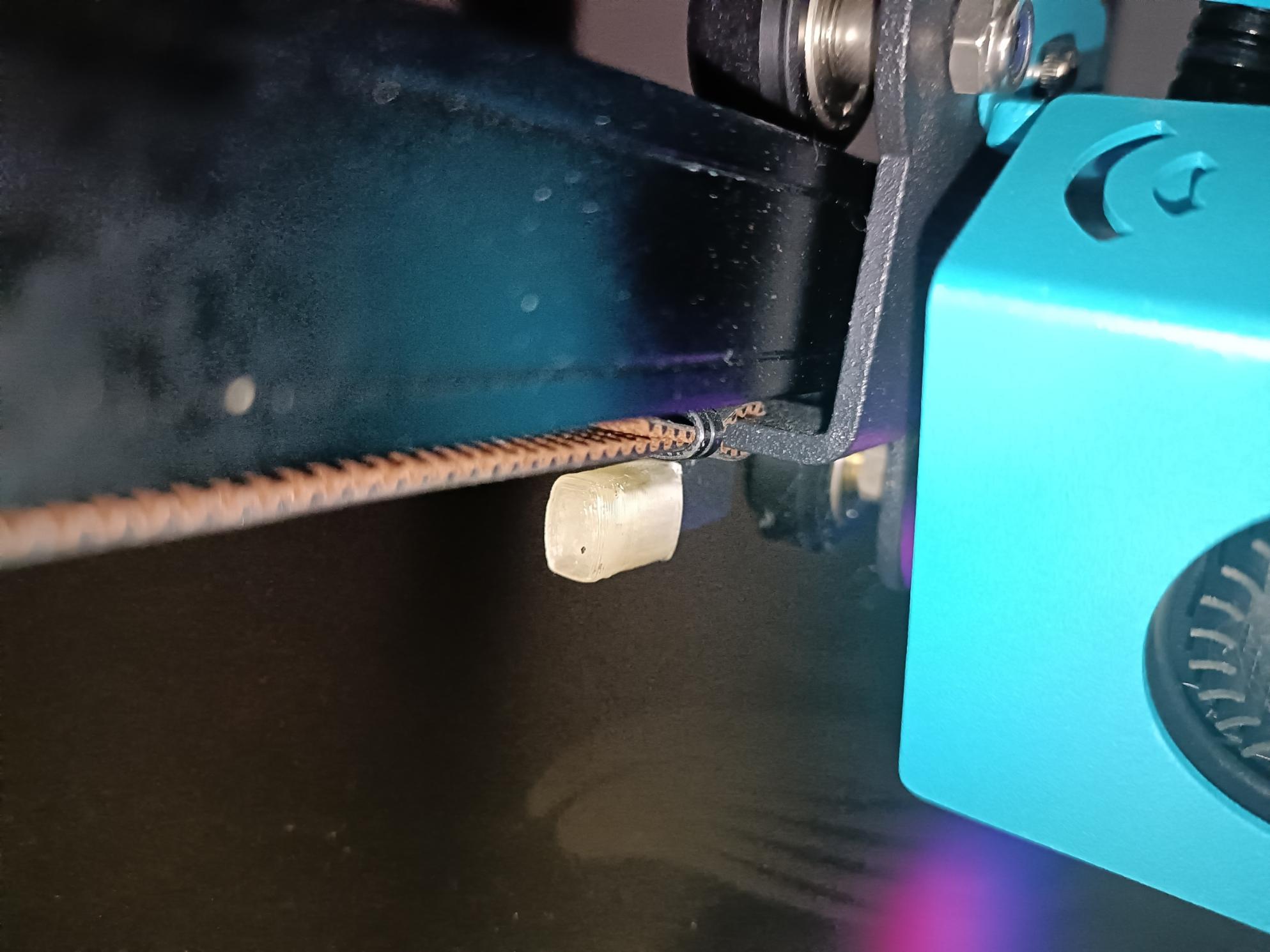

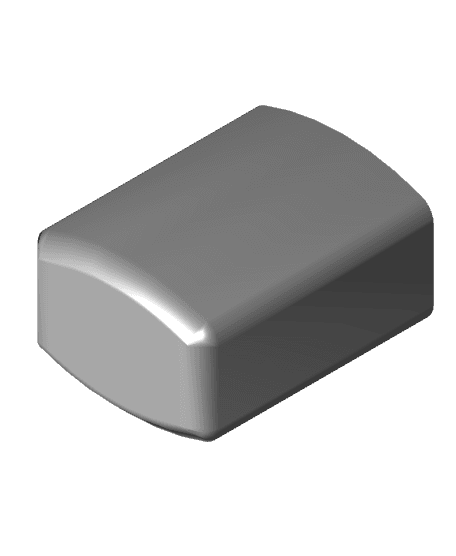

This design solves the X-axis by adding a boot to extend the trigger by 5mm.

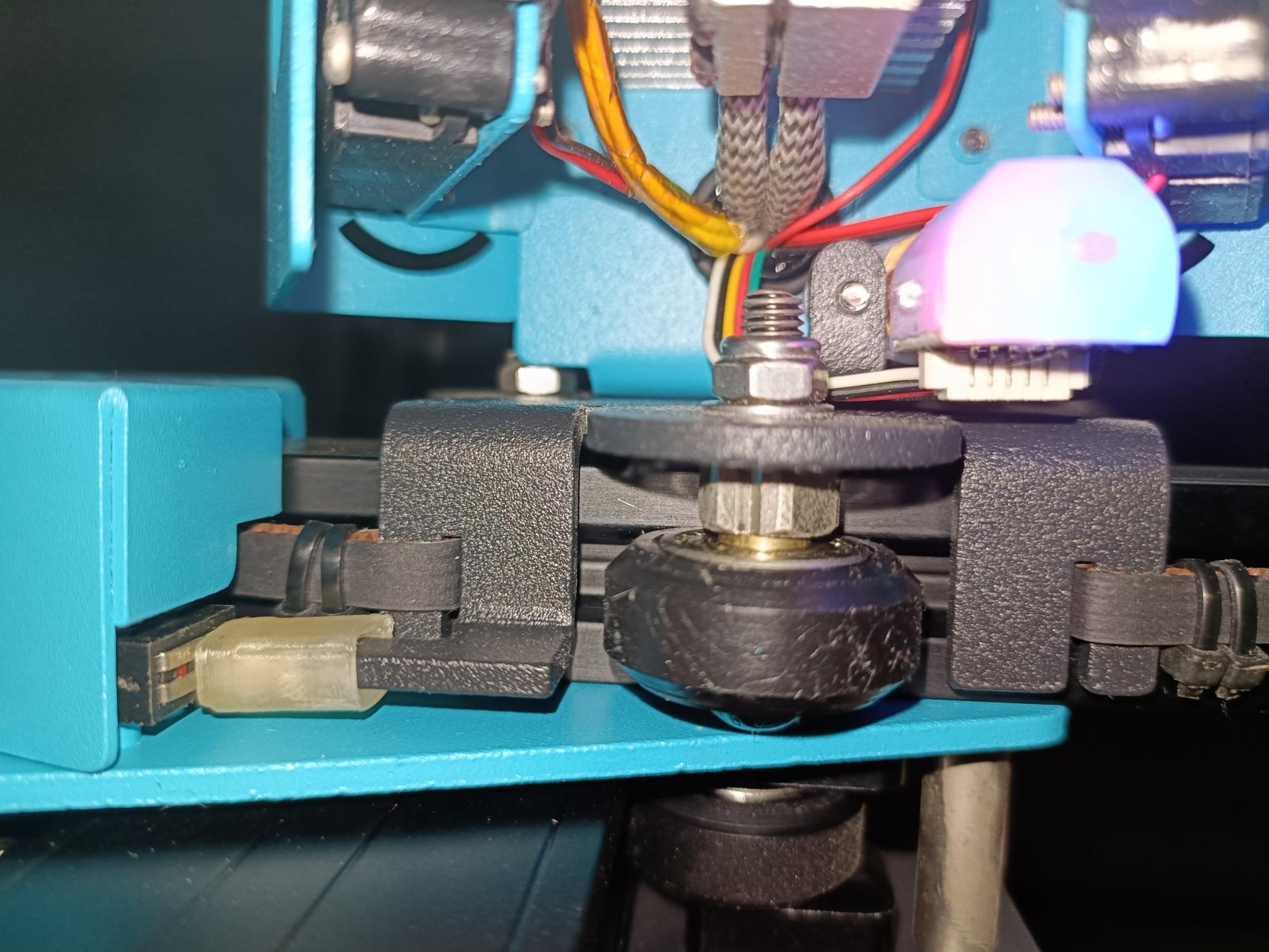

Y-axis trigger is a screw, and while easy to get a working solution, I am thinking about how to implement a fix without disassembling a lot of parts.

Customisation hacks

-

If you like shorter than 5mm, move the part down to your desired height on the slicer bed. It should only slice the 3D model that is above the bed.

-

If the part is too tight or loose, play with the scaling by 1% to 2% increment till you get a good fit.

As always, everyone's 3D print will be slightly different. Play around with the slicer to resize the part to fit.

Want to buy me a coffee? https://www.buymeacoffee.com/zer0s

Clicking on my affiliate links below will give me a small kickback if you purchase something. (at no extra cost to you)

AliExpress affiliate link: https://s.click.aliexpress.com/e/_DeAZr9P

Consolidated affiliate links of other 3D printing-related items: https://wp.me/peMLu6-j

For Amazon affiliate links https://wp.me/peMLu6-2C