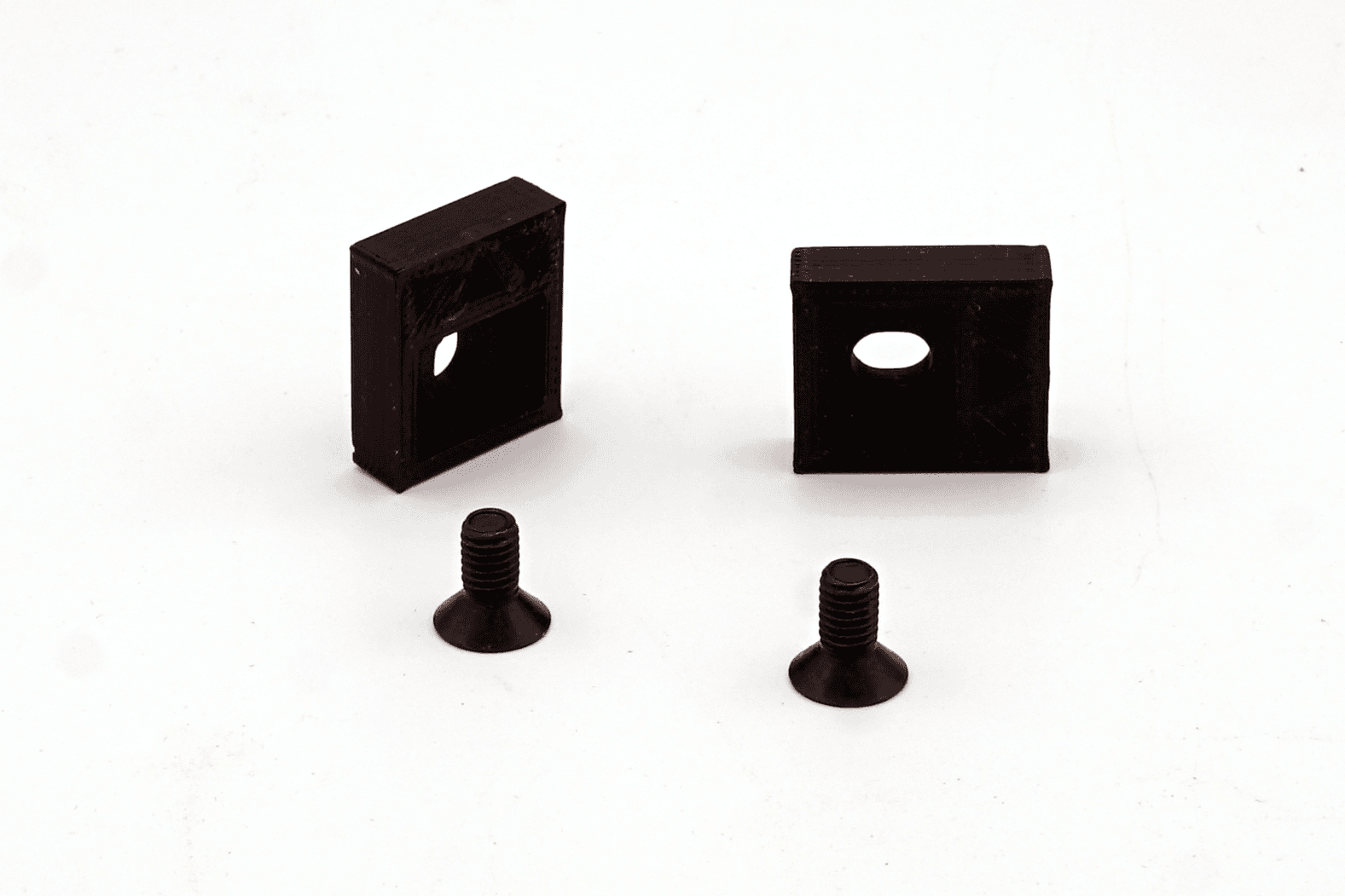

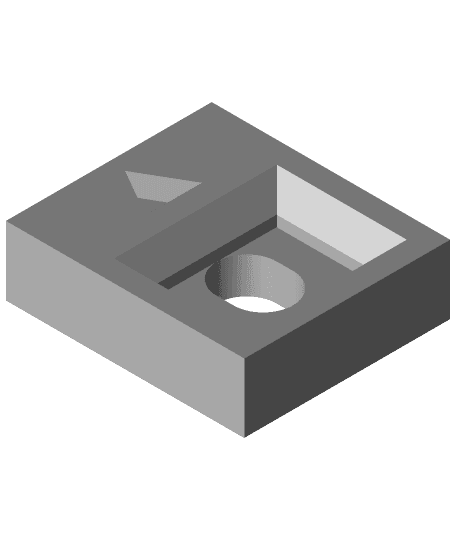

This is a low-profile 3D printed clamp (1/4" tall) that presses into your stock material from the side when a 90 degree countersink bolt is screwed through it.

The entire clamp is 1/4" tall, so it is great for thin pieces of stock material that need to be carved/machined on the entire top side.

This clamp is for use with CNC routers that have wasteboards/tables with M5 threaded inserts, like these: https://amzn.to/3wUoazT or aluminum extrusion with T-nuts.

The total movement of the clamp is 1.5mm. This isn't much, so it is recommended to pair this clamp with the low profile sliding right-angle jig. This jig allows you to press the stock material right up against the face of the material, then all 1.5mm of travel will translate to holding force.

The arrow should point towards the stock material.

Materials: It is strongly recommended to purchase this bolt from McMaster-Carr because its 90 degree profile is what actually forces the clamp forward when it is tightened: https://www.mcmaster.com/91294A211/

3D Printing Parameters: -100% infill -Due to the small features and high clamping forces, it would be optimal to SLA print this model out of a tough resin

Check out this video see my 3D printed work holding in action: https://youtu.be/cU-LR5Mn9fY