REMIXED FROM: https://www.thingiverse.com/thing:4927953

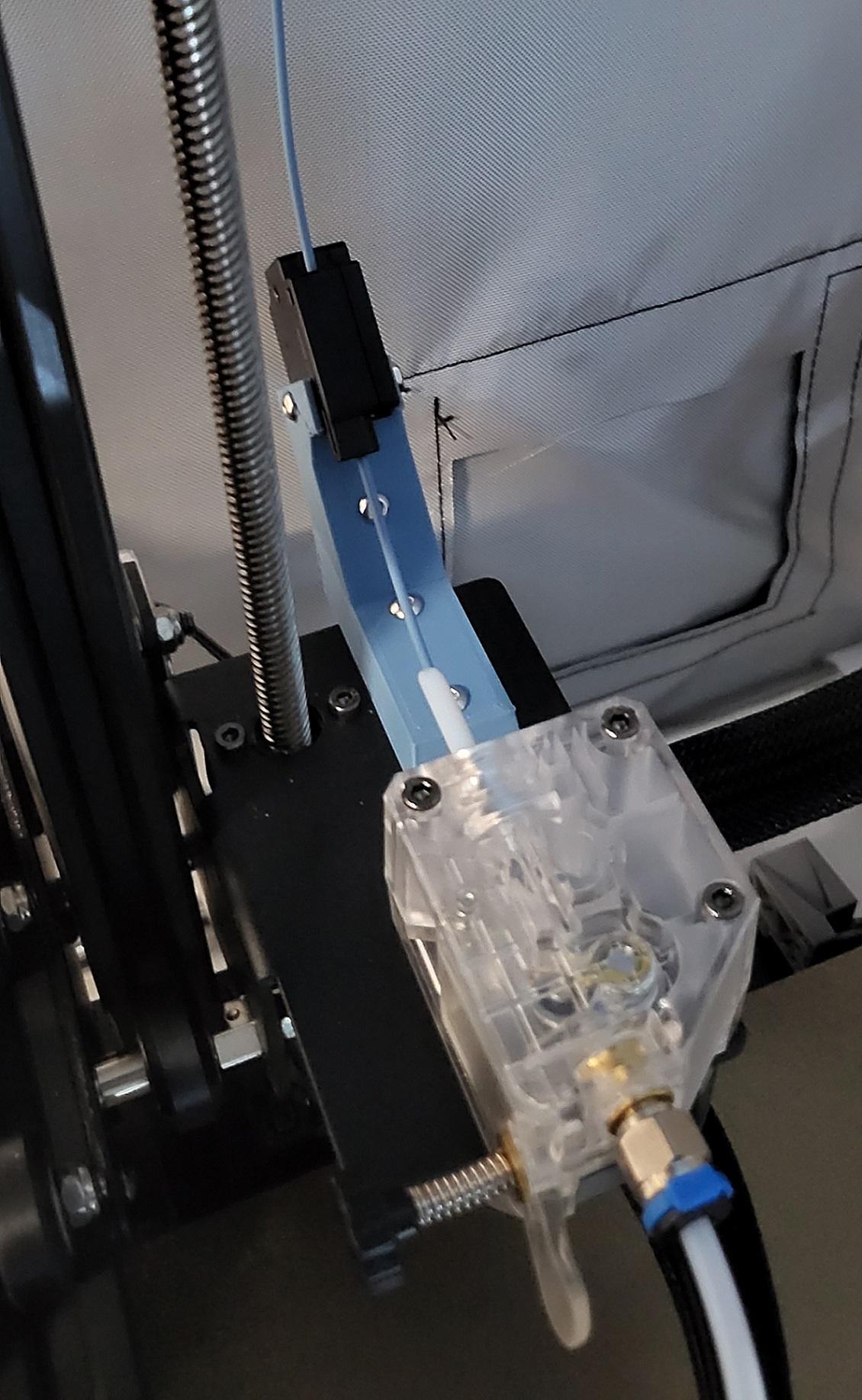

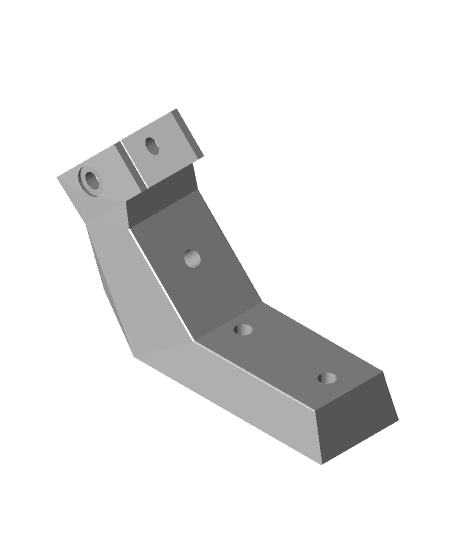

This is my remix of the stronger Vyper filament runout sensor adapter, modified to be at a 45 degree angle for top-mounted filament configurations.

Due to enclosure size restrictions, I had to mount my filament spool on the top of the gantry. I didn't like the 45 degree adapter options available, as the filament runout sensor is attached by a single screw on a flimsy plastic arm out of the box. I had some concerning noises during retractions.

The following modifications were made to the original design:

- Extended sensor mount point and angled upwards 45 degrees

- Added additional M3-sized (3.5mm) screw hole on 45 degree offset

- Expanded size of filament sensor arm channel (it's now enclosed)

- Flattened bottom to eliminate need for any supports

To install, I used the following:

- 2 x M3x20mm screws

- 2 x M3x16mm screws

- 2 x M3 nuts

To attach to the Vyper:

- Completely remove existing filament runout sensor, including the metal tab it attaches to (2 screws total).

*** Note that this will drop the X-axis gantry control board below, as it is only held in place by those 2 screws. Be careful!

- Attach the filament runout sensor to the printed adapter using the 2 M3x20mm screws, and 2 M3 nuts.

-

One screw will go through the normal mounting hole, the other will go through the side hole that was previously unused.

-

Don't secure either too tight, just snug!

- Attach the entire thing back to the X-axis gantry using 2 M3x16mm screws. It should sit flat on the gantry plate, and the screws should hold the control board snugly.

Note that I had previously cut short my Bowden tube going into the extruder assembly, so I'm not sure that's a necessary step for everything to fit correctly.