Collapsing Master Sword with Replaceable Blade

by3dprintingworldCollapsing Master Sword with Removable Blade

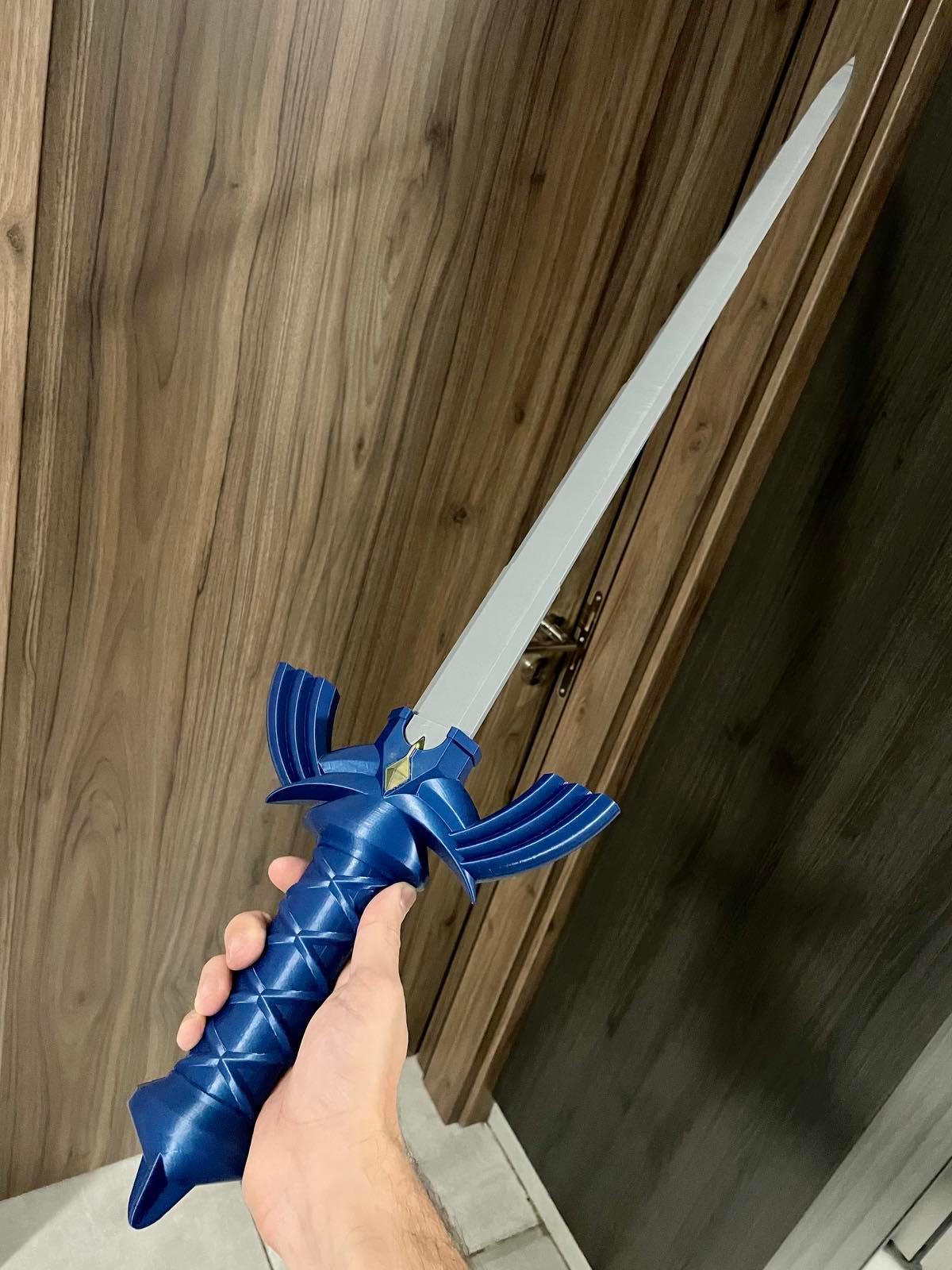

Unlike the Print-N-Place version, the pommel on the hilt of this Master Sword is threaded which allows the blade to be printed separately and inserted. The assembled hilt is 250mm long but the blade extends to a length of 870mm long in total!

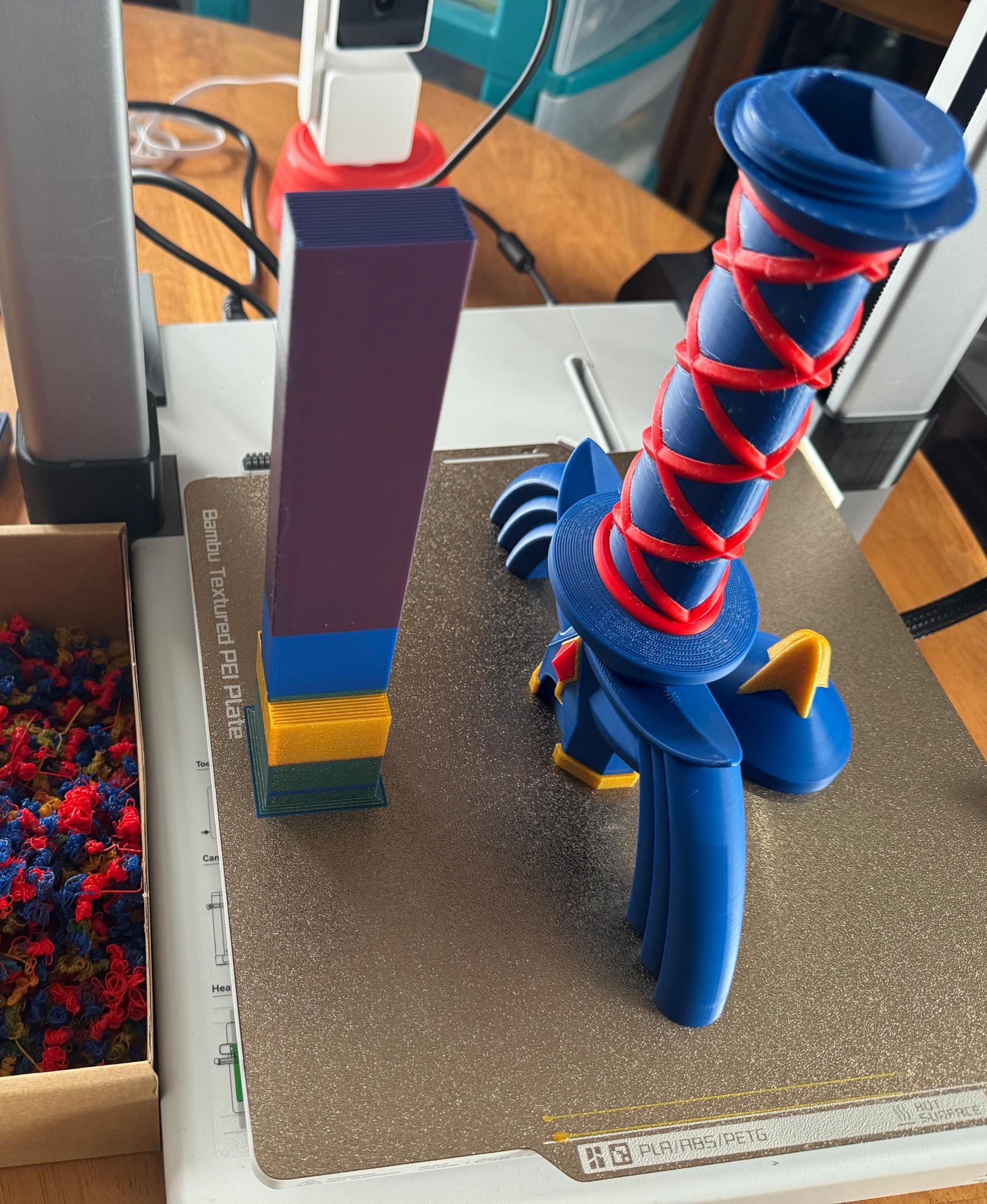

Printing The hilt and pommel do not require supports. The blades can be printed concentrically as an assembly or individually in vase mode. If you plan to print concentrically, a single stl contains all the blades. If printing in vase mode, there is a stl for each blade. Note the vase mode stl’s are supposed to be solid so the slicer knows not to make an internal perimeter.

Vase Mode I prefer printing the blades in vase mode as the result is a much cleaner and easier print that can easily be scaled. If you print sequentially, it’s faster too. If printing at 100% scale, set the line width to .85mm. If you plan to print it smaller, scale the line width down by the same about. If printing in vase mode you can scale down to a minimum of 55% with a .4mm nozzle. For vase mode turn top and bottom layers on for the first blade, but turn it off for segments 2-5. You will notice that the vase mode files are solid, this is so your slicer knows not to try to build a inner perimeter.

Concentric When printing the blades concentrically use a .4mm nozzle and set the line width to .42 so the blades are two shell thick. If you would like to scale it down try printing the vase mode version instead. Before printing the blade assembly make sure perform the test print found here This print is sensitive on the layer seam and might need to be tuned so the blades don’t fuse.

Test Print The test print is a total of 24mm high so I change retraction settings every 8mm. Then I compare the changes until I achieve the best result. Each printer is going to be different but in my case I used a negative “extra restart” distance to reduce the size of the layer seam.

Detailed printing instructions can be found on my website

Note: Assembled 3mf file for reference only

Printed with 3D Fuel Cobalt Blue and Silver Pro PLA

Printed on the Muldex rep-rap IDEX printer.

Master Sword Versions Print-N-Place Dual Extrusion Three Color

Note: Assembly model for reference only.

Having troubles printing or want to show off your prints? Join our Facebook Group.