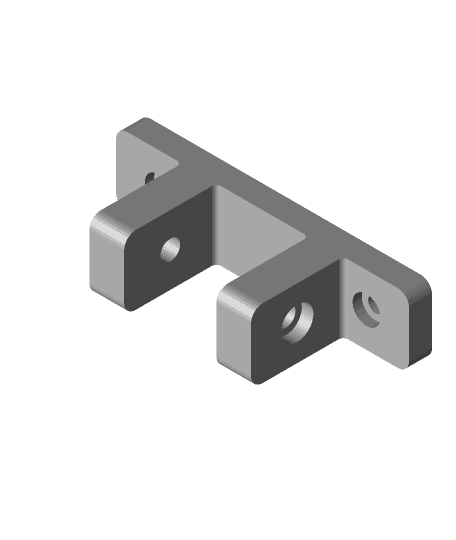

Fanatec SQ1.5 4040 Aluminium Mount Bracket

Existing solutions available on the market either put the shifter too far away, too close, or encroached into the seated area of the rig. These brackets put the shifter directly over the 4040 extrusion.

You'll need to print two - one for the front and one back. Should slide nicely onto a bit of extrusion with a width of 40mm. Print with the two prongs facing upward - no supports should be necessary.

Other hardware required:

- 4 M6 x 20mm bolts with head diameter of less than 12mm to hold the brackets to the shifter. The 20mm is important here to ensure that the screws don't go more than 15mm into the shifter, as per the Fanatec drilling guide for the unit.

- 4 M8 x 20mm socket cap bolts to attach brackets to profile.

- 4 M8 Slide nuts.

This is for a 0.4mm nozzle, adjust as appropriate to your printer:

- Increase the number of walls to 8, this creates a solid block where the bolts connect to the shifter

- If possible in your slicer, set the infill or number of walls in such a way that it creates a solid (100% infill) for the holes that the bolts go through for the profile.

These settings ensure you can tighten up the bolts plenty, without risk of crushing the plastic easily.

2 Likes11 DownloadsMay 19, 2022

2 Likes11 DownloadsMay 19, 2022

.jpg&w=3840&q=75)

.jpg&w=3840&q=75)

.jpg&w=3840&q=75)