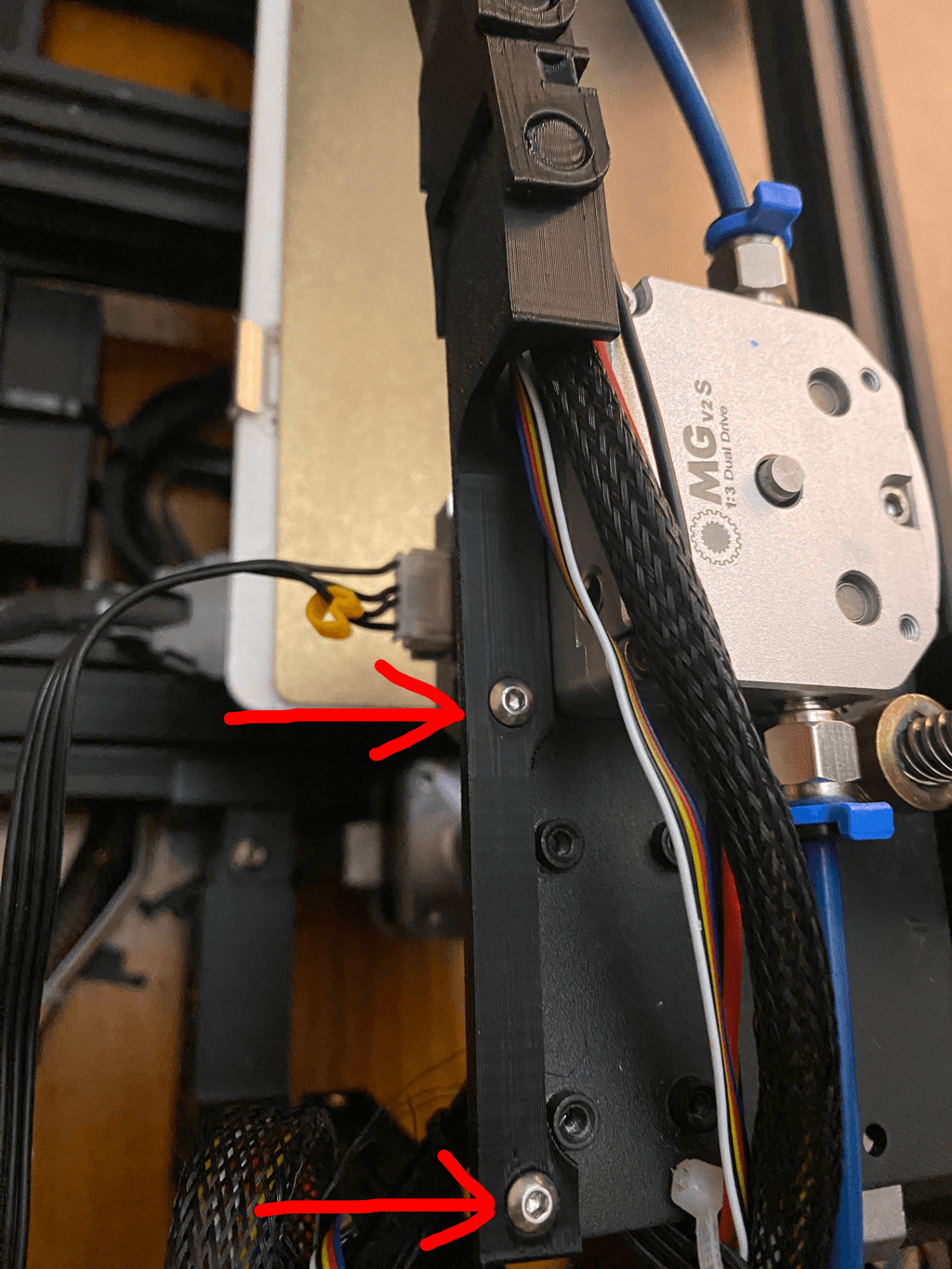

Ender 3 Max Cable Chain Solution

I should note, I haven't tried this with the stock extruder. I use the OMG extruder v2 in a bowden configuration.

This has been tested with a direct drive set up as well, and works with the motor mounted in any direction except for the right.

I've spent the better part of 6 months printing, and reprinting many different iterations of drag-chains, or cable chains, for the Ender 3 Max. I think I came up with a pretty decent solution. I have removed my filament runout sensor, but this should still work with it.

This package contains 4 files.

- Hotend Connection

- Extruder End Connection

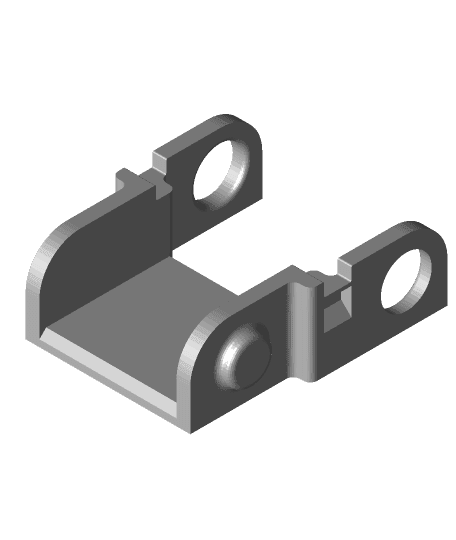

- Cable Chain Link

- Cable Chain Cap

I HIGHLY recommend printing these parts in ABS, or a similar high temperature resistant filament. PLA will end up sagging, and failing over time.

All of these parts are oriented in the correct printing position aside from re-centering the models.

No supports are needed. *The cable chain end links printed fine with NO SUPPORT in all 30 different test prints I did plus all the chain links. They will print fine with NO SUPPORT.

Print the following amounts:

Hotend Connection 1 Extruder End Connection 1 Cable Chain link 15-20 Cable Chain Cap 15-20

You will also need: m3x8 x2 m3 nut x2

Recommended Print Settings Filament: ABS, ASA (any high temp resistant filament.) Resolution: .2 Infill: 40% (Triangle, Gyroid, Cubic) Supports: None

STEPS:

-

Hotend connection is designed to slide into the top, back part of the stock Ender-3 Max x-carriage. The cable chain connection should be on the right side of the x-carriage plate. [The side closest to the LCD] It'll be a tight fit, but it is meant not to move.

-

Extruder End Connection. Remove the 4 screws holding the filament runout sensor on, and remove sensor. Place extruder end connection on the far left side of the extruder arm mount and line up the two screw holes. Insert screws and secure with nuts from the bottom. This piece is designed to be a bit flexible to be able to route your cables into the chain. Be gentle, this piece may also be a bit fragile.

-

Replace filament runout sensor

-

Link 15-20 cable chain links from the extruder end connection to the hot end connection. Connecting links to the Hotend Connection and the Extruder Arm Connection are going to be very tight. They are designed to be pretty firm to help them from popping off easily. Print extra pieces incase anything breaks. Be careful connecting to both Extruder end and Hotend side.

-

Add 15-20 cable chain caps to secure your cables inside of the chain.

That should be everything. Let me know if you need help.

This is based on a few different designs found on thingiverse, and here on thangs. I'd like to credit "OpenDorrPolicy " for the base hot end design, and "neilbalch" for the cable chain link and caps. Check out their designs!

The Hotend Design was initially designed by OpenDorrPolicy on thingiverse. I remixed the creation to make it thicker, denser, fit better, and re-designed the holes to fit the chain links.

The Chainlinks and chain caps were based on a design I found from neilbalch, here on thangs. They are unaltered. They are the most superior printed cable chain design I have been blessed to come across. I recommend them highly for any cable chain need.

The Extruder Arm Connect was designed entirely by me in Fusion 360.

**This is a work in progress. While this part is functionally complete, I am in the process of designing it to look a little better. The cosmetic design will change over time