MAKING AND USING YOUR OWN TATTOO MACHINE ON A HUMAN WITHOUT PROPER TRAINING AND APPRENTICESHIP IS DUMB. DON'T DO IT.

Screws required: 2x - M3-0.5 x 6 - Motor mount 1x - M3 x 20 - Tube vise 1x - M3 Thumb Nut - Tube vise 1x - M3 Lock washer

Extra parts needed:

-

Motor: Mabuchi RK-370CC-14230 is the best I've found so far. You will need to trim a few millimeters off the output shaft with a dremel cutoff wheel or something to get the cam wheel to sit against the motor and line up correctly. I used some duct tape to wrap the motor, but that's up to you.

-

Tattoo cartridge grip

-

Rotary tattoo cam - can be found on ebay

-

Female 3.5mm Jack

-

Male 3.5mm Jack - Use this to convert an existing clip cord to 3.5mm.

You may have to drill out some of the printed holes to make the parts fit better. I've found that it is helpful to drill out the grip hole on the clamp, then let the smooth part of the drill bit spin quickly in the hole until it heats up and smooths out the plastic. This allows the grip to slip in and be moved around very smoothly.

Any tattoo power supply should be able to run this machine.

Seems to be fine with less infill but some sections, especially the clamp, are under quite a bit of stress, so setting it to 100% doesn't hurt.

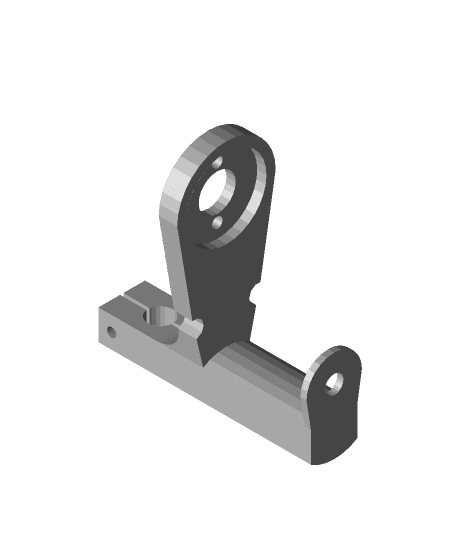

The machine should be printed laying horizontally on it's side with supports for maximum strength.

.png&w=3840&q=75)