Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:4854052.

<strong>Parts in this Dual Air Duct Thing is made for the Swiss3DC Starlex All Metal Hot End No Screw, No Tool Hot End. </strong>

The only different part to adapt the Original Ender3_V2 (same base plate for Ender3; Cr10; Cr10S) Hot End, is to change the Green part shown below, it is called the Spacer 10mm high instead of 9mm. For the fans, it's up to you. Check this Thing for full set of parts: https://www.thingiverse.com/thing:4791834/

This <strong>Dual Air Duct</strong> is adaptable in many ways. Originally designed for the Ender 3-V2 model, reusing the 4011mm Original axial Fan as Nozzle cooling. The original fan is loud, you will probably wish to change it with a quieter one and higher performance 4020 axial fan! Many options are available. I like flexibility in designs. Pick up the parts you need and print.

<strong>No tool nor screw needed</strong> to mount this Dual Air Duct, either for the fans and the support on the X carriage of the Ender3_V2 and same.

Air Duct itself is <strong>WITHOUT support</strong>. I made it out of PetG and PLA basic 0.2mm Cura setting but can probably be made with any other material brand as it is far enough from the Heat Block. The Dual Air Duct Support, part clipped on the X-Carriage plate and a little clip would need small support.

The stl files are standard parts needed to mount the Dual Air Duct on the X Carriage of an Ender3_V2, Ender3, Cr10, Cr10s... X plate mount.

Designed for 2 40x40mm fans, one axial, one radial, the Heat Sink Fan and the Nozzle Fan with a wide Dual Air Duct for best air flow and part cooling.

Lowering the power for the Heat Sink Fan makes it quieter. I used a 1K Ohm 10 turns adjustable resistance, as a "tension divider". It works great with no overheating and Heat Sink cool enough for my 12h prints.

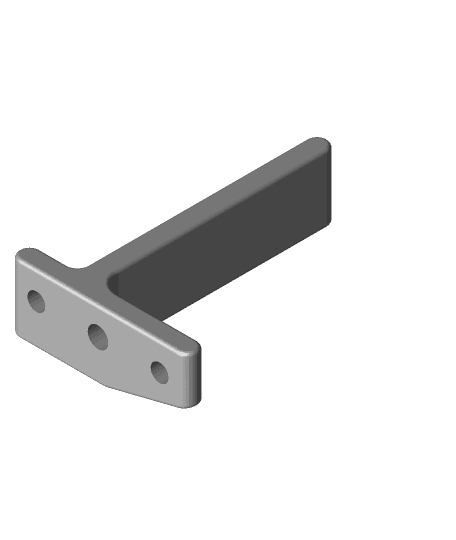

The <strong>Air Duct Support </strong> is <strong>clipped to the X Carriage</strong>, on the two wheel axis, made for 40mm inter axis wheels and 2.5mm steel plate thickness. There is a hole at the back facing a threaded original hole in the plate, in case you want to secure it. I never did. <strong>Tiny support</strong> will be needed here, for the wire clipping axis.

Depending on the type of Hot End you have mounted, <strong>you can choose the height of the Spacer</strong> that will come between the Air Duct Support and the Dual Air Duct, (for the Bowden original Hot End, the 10mm Spacer is needed) Changing this Spacer permits to have the nozzle air flow at the correct height. FYI, Air flow tends to follow the external wall curve, this is where most air "pressure" goes. The air flow will make kind of a V shape, under the Nozzle.

The <strong>Dual Air Duct has an internal median wall</strong>, to spread the air at the output more evenly. It's output is wide to manage a high air flow with low pressure on the filament and cooled parts. Wide also for multiple Hot End mount, if it needs to be further away from the carriage plate.

<strong>Something never seen before</strong>, for easy access to the Hot End, the <strong>Dual Air Duct is mounted on an axis</strong>, lifting it slightly then rotating. It is all what is needed to have a wide access to the hot end. Depending on your printer precision, and print quality (flow amount, Stepper motors settings) there can be more or less play in the printed shaft axis,<strong> first print 2 </strong>of the <strong>Sample Shaft Prints</strong>. (I might need to adapt the size by 10th of a mm depending on your feedback)

The top 4011mm Fan for the Nozzle is the original Heat Sink Fan, with 32mm inter axis holes. A simple U shaped Clip stl provided will hold it in place. Different Clips Height are available. As the original fan 4011 is a little weak, I have replaced it with a 4020mm fan, 24Volts from SUNON. Update, at low speed = low voltage value 86/255, it tends to stop, quality matters?

Also never seen before, a <strong>Special Fan Plate with a V shape mount</strong> has been designed for <strong>Multiple Heat Sink Fans</strong>, it can be any flat Axial Fan, 30 or 40mm fan, most Radial Fans 40x20, 4015, 5020, 5015mm depending on the printed part you have chosen.(50mm fans there are ok with standard Hot End, Nozzle end tip at 72mm from top of the X carriage plate) Insert the Heat Sink Plate part into the V shaped mount. Height is adjustable, little locks will maintain its position. Not all fan options have been designed yet. Check various parts on Thing: https://www.thingiverse.com/thing:4791834/

I do not have a <strong>BL touch</strong>, but I have designed the Air Duct Support with a <strong>ready to mount BL Touch</strong>, adjustable in height. A Eccentric shaft is designed to hold in place the BL touch, at the chosen height.

This is my first share, be indulgent with my concept, light adaptation might be needed depending on your feedback. A TIP is always a nice way to say thank you for the job done.