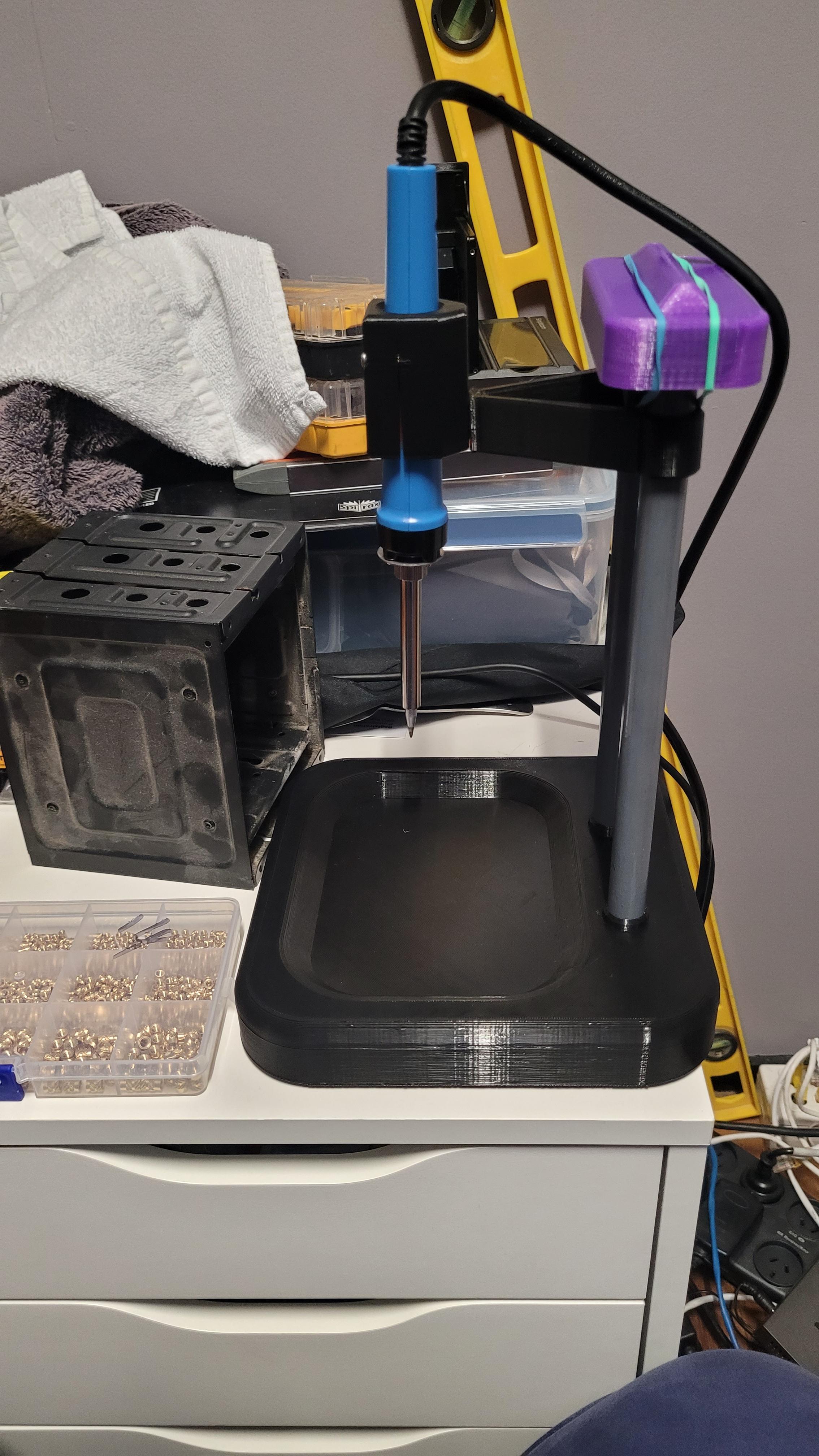

Budget Heat Press Insert Tool (Cheap & A bit Janky)

byKhalm Down HobbiesThis is a super cheap budget version of my Heat set insert tool. It uses simple cheap components and easy to print models in order to make a solid platform for repetitive heat set inserts or other Press style tasks. The build process is very simple and all of the parts make clear sense how they go together. The tolerances on all parts might need to be tuned based on machine but my tuned and untuned machines were able to knock out the V1 version for it to be functional. In my version I’ve used Rubber bands to add spring actuation and am using Singer oil for the slides, I would recommend grease for the slides but rubber bands seem to work well. BOM Complete as follows: 2x 16mm Curtain rods (offcuts at 270mm in my case) 2 x M3 x 12mm Hex Sockets 2 x M3x16mm Hex Sockets 4 x M3 Heatset Inserts 2 x Rubber Bands 4 x Sticky rubber feet 1x soldering iron (Mine based in Duratech TS-1554)

Printed parts as follows: Printed Base, Top, Mount are relatively ubiquitous. Clamp back and front were made to suit the TS-1554 which is a cheap soldering iron sold by Jaycar here in Australia.

** V1_1 updates to a couple of parts including 1mm widening of mounts, 0.1mm tightening of clearances around the slide. Updated to Top piece rubber band mounting and other minor improvements to improve printing performance. Please if you make any changes or mounts for this chuck them in the remix tab and if you find anything needing some revising comment on it. Makes are always awesome to see as well.?

Print Settings: I printed this in Esun PLA+ at 3 walls 3 top/bottom with 5-20% infill depending on the part. In my case this Iron doesn’t have heat creep issues so I have not had any concerns about the materials used. Printed all in the orientation that I have exported them with no supports on anything and no brims or rafts needed.

V1_1.png&w=3840&q=75)