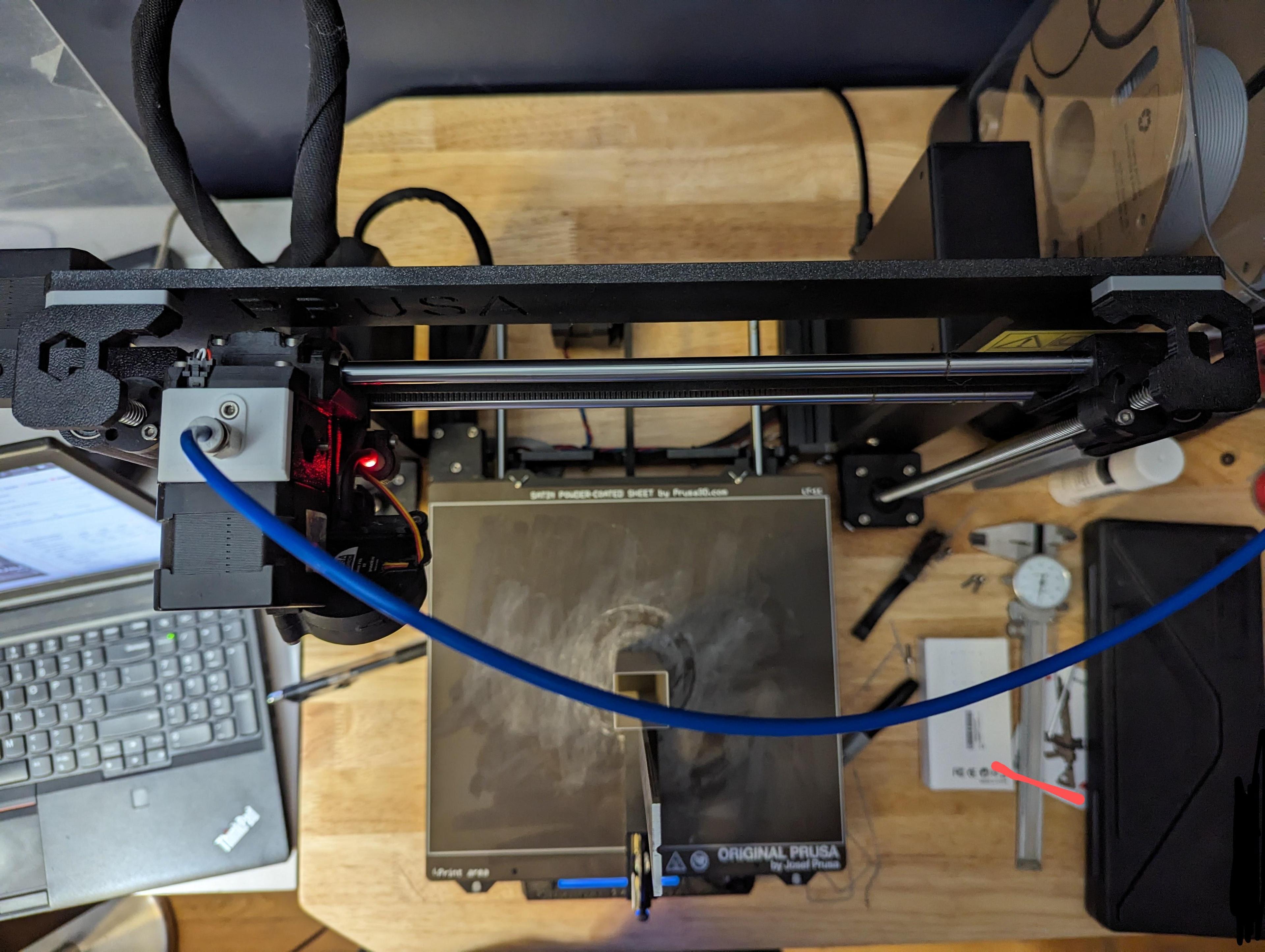

If your Z axis is out of square in the Y-Z plane (leaning towards the back) then this spacer might be useful for you. I just extruded it from the profile of the top bracket released by the manufacturer.

You can calculate the thickness with a simple linear relation. Print a tall rectangle, place a square against the base and use a caliper depth gauge or whatever to measure the deflection at the height of the measurement from the build plate. Then using the length of the linear rod (~12.25") you can get a spacer thickness in inches with (deflection / measurement height) = (spacer thickness / linear rod length). Or use a protractor and trig like a fancy person.

Make sure to use longer fasteners and not strip the threads in the frame. I had some M3x12s that worked well but slightly longer would be better.

One degree off might not seem like much but my parts couldnt be assembled as a result!