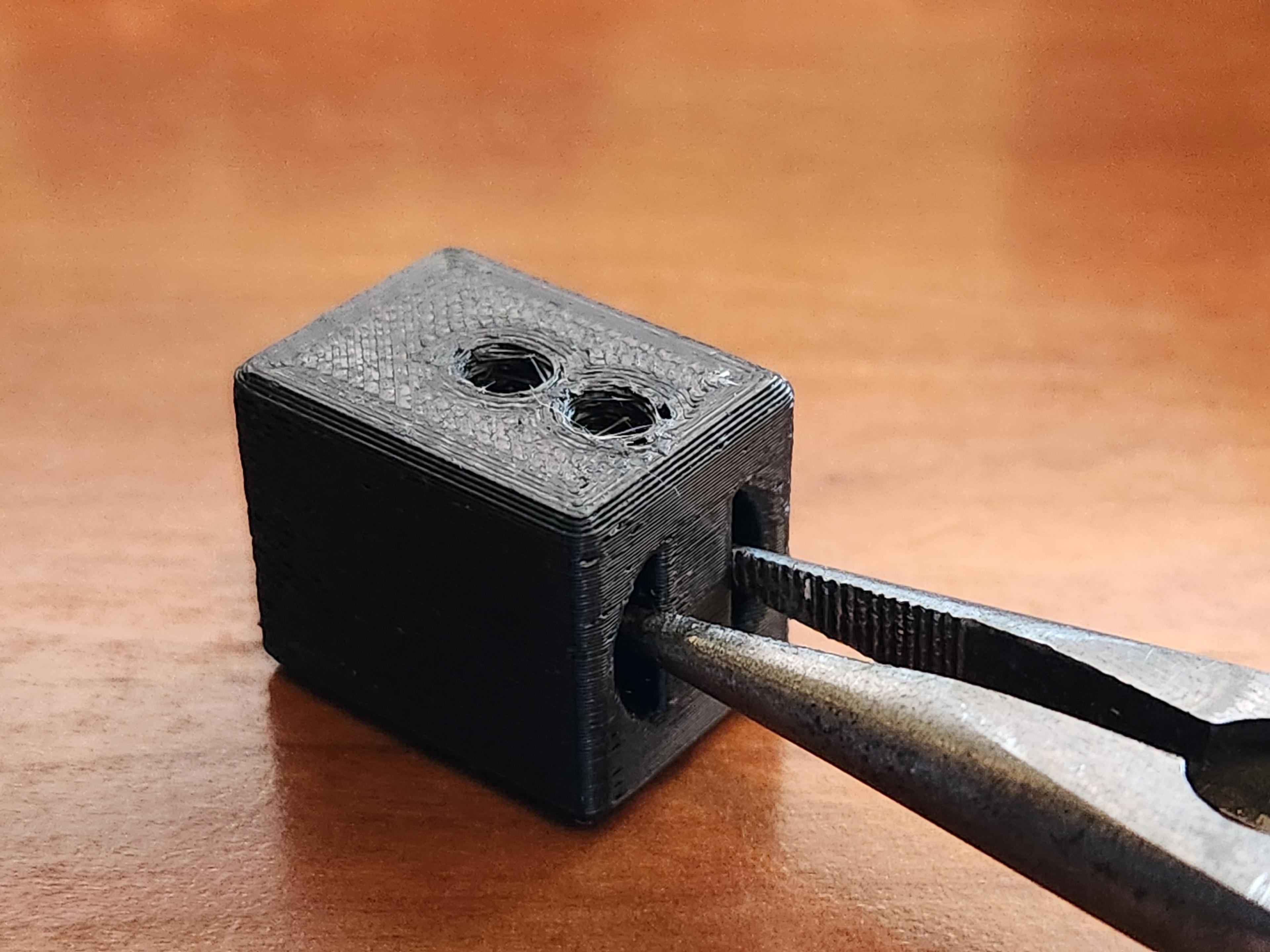

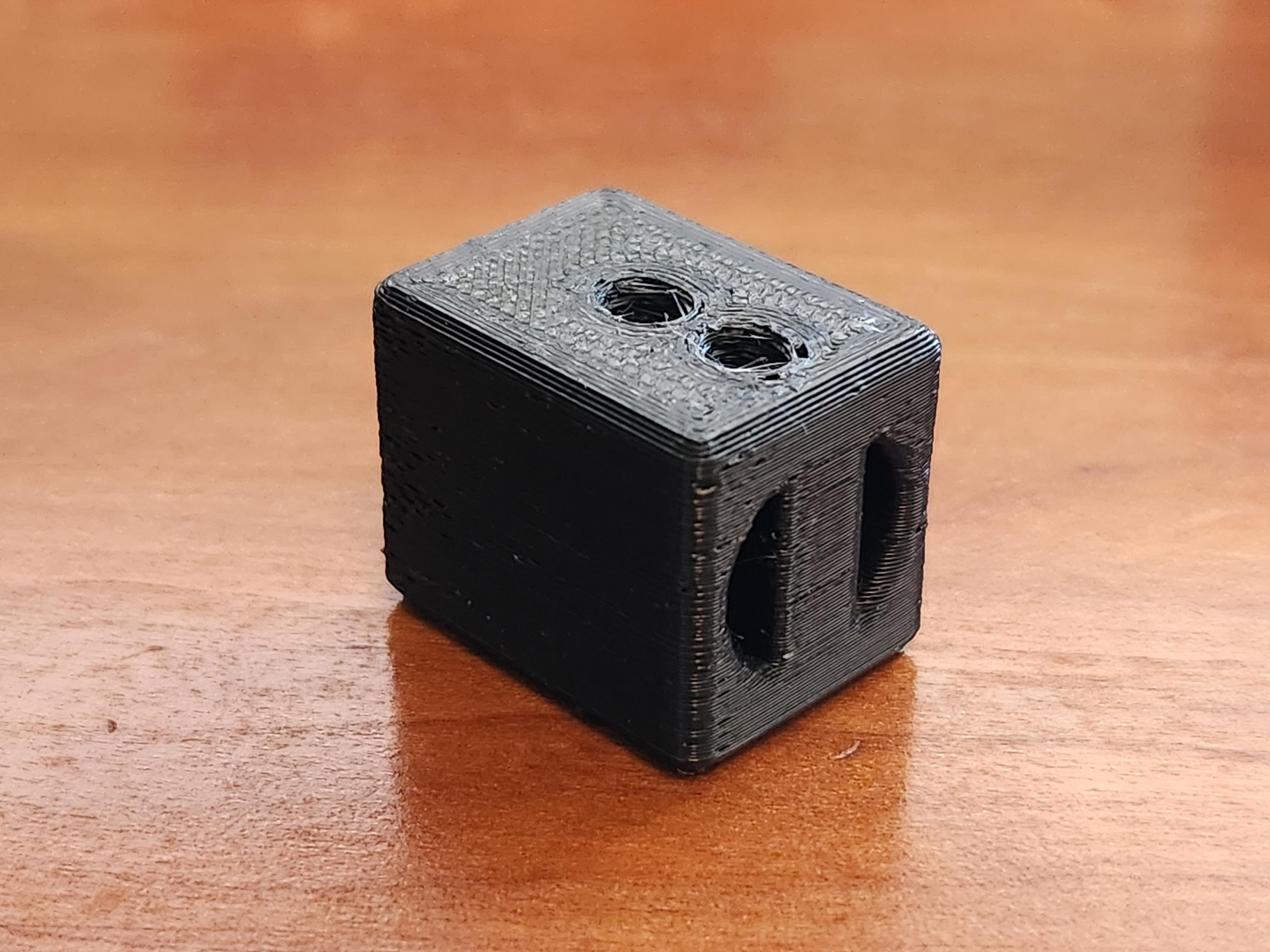

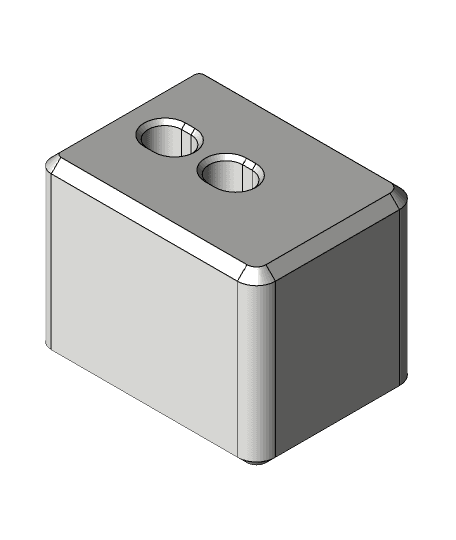

Modified the end block that goes inside the carbon fiber tube of a VzBot 3D printer. Rounded the vertical edges so it's easier to print, made the height and depth into parameters, and changed the end of the block to use a pair of cutouts that are meant to be gripped by needlenose pliers when removing. Also made the block 18mm tall so it's tighter, and left it 17.5mm deep so it's looser horizontally. The idea being that it should be loose horizontally so when testing tightness it's only the vertical clearance dictating how tight it is.

Would recommend loading the F3D file in Fusion and changing the height and depth parameters until it's loose horizontally but tight vertically. Other alternative is to print it a little taller than it should be and use sandpaper on the top/bottom faces until it fits tightly but without forcing it.

Original end block is here: https://github.com/VzBoT3D/VzBoT-Vz330/blob/master/Assemblies%20BOM%20and%20STL/Gantry/X%20Carbon%20fiber%20tube%20%2B%20rail/STLs/cf%20tube%20end.stl