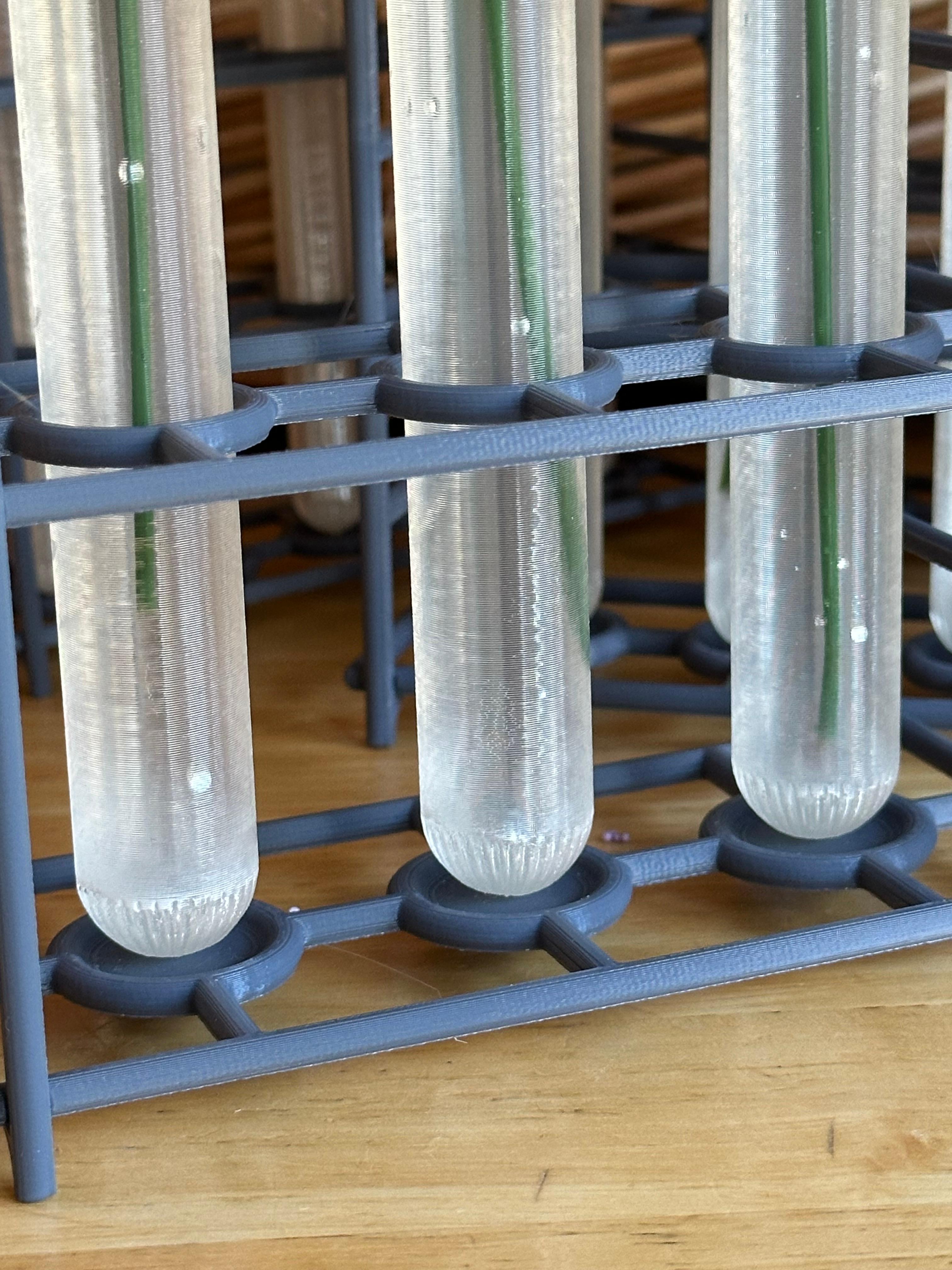

These “Test Tubes” can be used as flower holders, seedling holders or as a toy chemistry set!

See here for video: https://youtu.be/Yl8F2EzHjo4

The models feature a special design feature that allows them to print in spiralized mode to optimize optical clarity. With careful printing and a bit of post-processing these test tubes can hold water!

Download includes five standard test tube sizes: 6ml (75x12mm), 10ml (100x13mm), 19ml (125x16mm), 36ml (150x20mm), and 55ml (150x25mm).

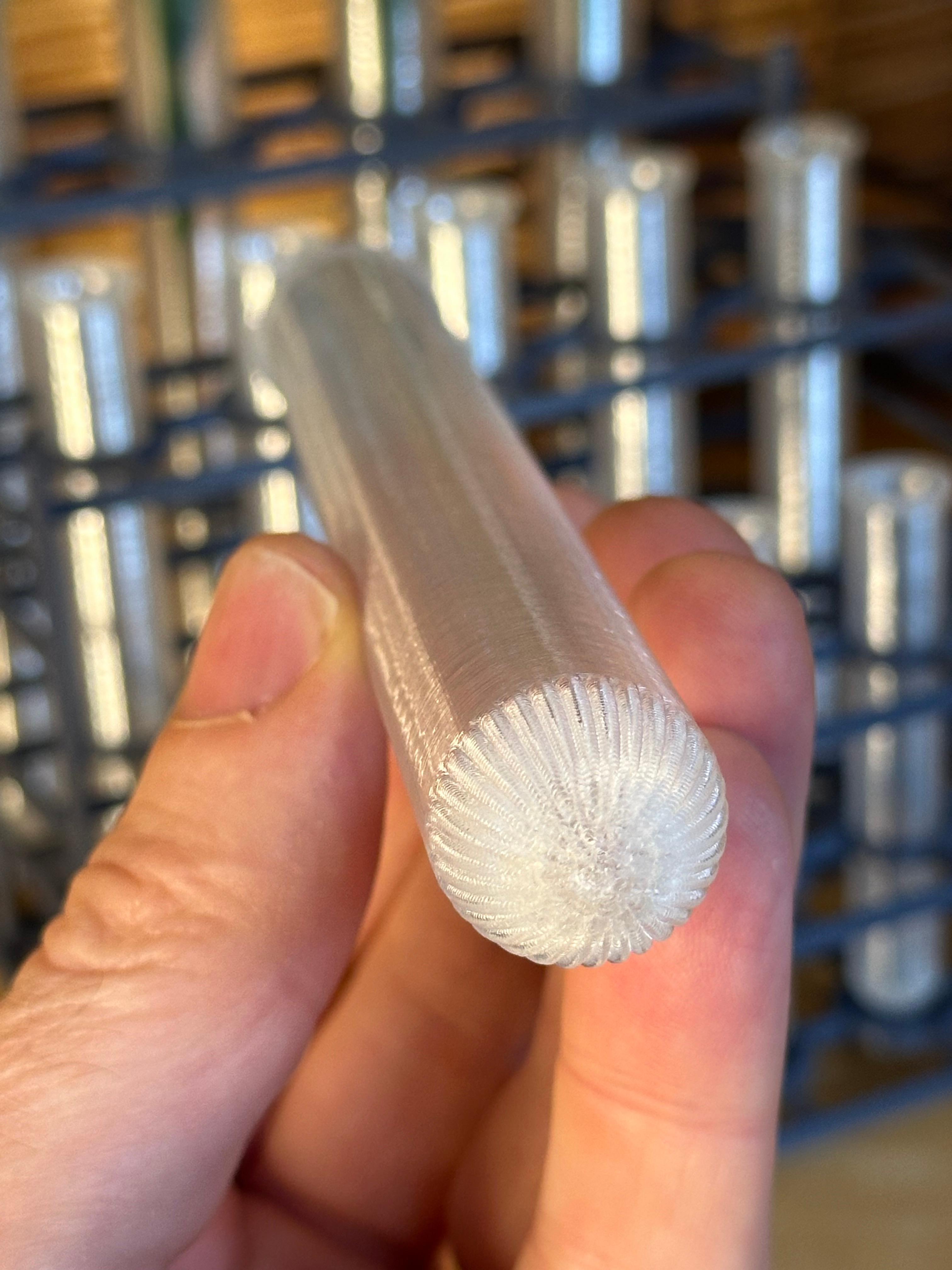

If you were to print a standard test tube shape in spiralized printing, the curvature on the bottom would result in poor layer adhesion, resulting in a weaker print that would not hold water.

If you look closely at these models, you will notice that there are a series of slits in the rim and curved bottom. When sliced in “spiralized mode,” these slits create a toolpath that traces back and forth over itself creating a stronger and more watertight surface than you would get otherwise.

There are 3 versions of each size. These different versions optimize the toolpath for different nozzle sizes. If you are not getting a good print with one, try a different one.

Print the files in spiralized mode as oriented with the bottom up. Set your “Bottom Layers” to zero and avoid using brim.

The small sizes are more likely to be watertight right off the build plate. In my testing, about 50% of the larger sizes are watertight right off the build plate. There are a few things you can do to make your test tubes watertight.

Decreasing layer height, raising the nozzle temp and increasing the flow rate a bit will result in better layer adhesion with fewer gaps.

The best and most reliable way to ensure watertightness is to apply a thin layer of gap-filling CA glue to the bottom of your finished prints. A well printed and sealed test tube will hold water indefinitely.

More rack designs are available here: Modular Wire Test Tube Rack: https://than.gs/m/988496 Solid Test Tube Holders: https://than.gs/m/995359