Roller blind motor attachment

Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:2011164.

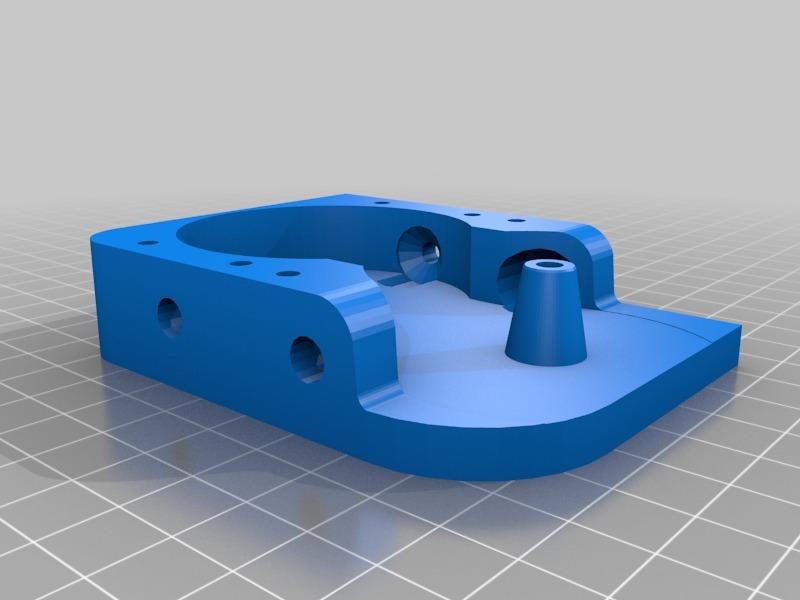

The "GidTech Window-Blackout-O-Master 2000™" attachment for a cheap roller blind from Argos. While more expensive, more substantial blinds can have a motor fitted inside the blind tube itself, cheaper roller-blinds have much narrower tubes.

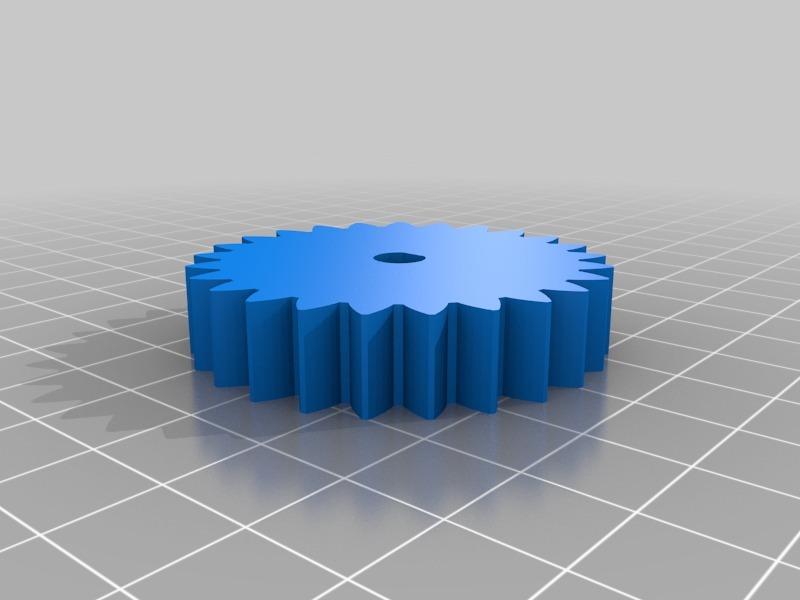

This attachment uses a 100RPM 12V DC motor - https://www.amazon.co.uk/gp/product/B01KTZXZ1G - to control the blind.

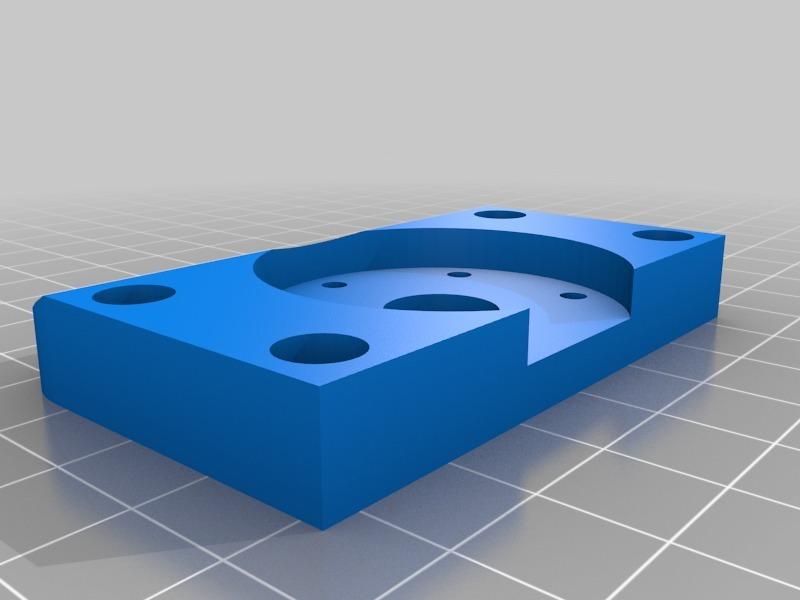

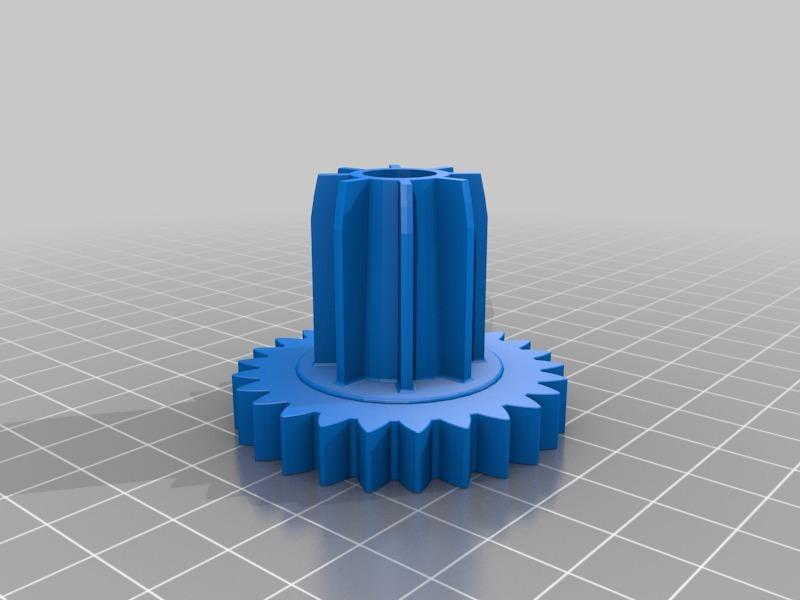

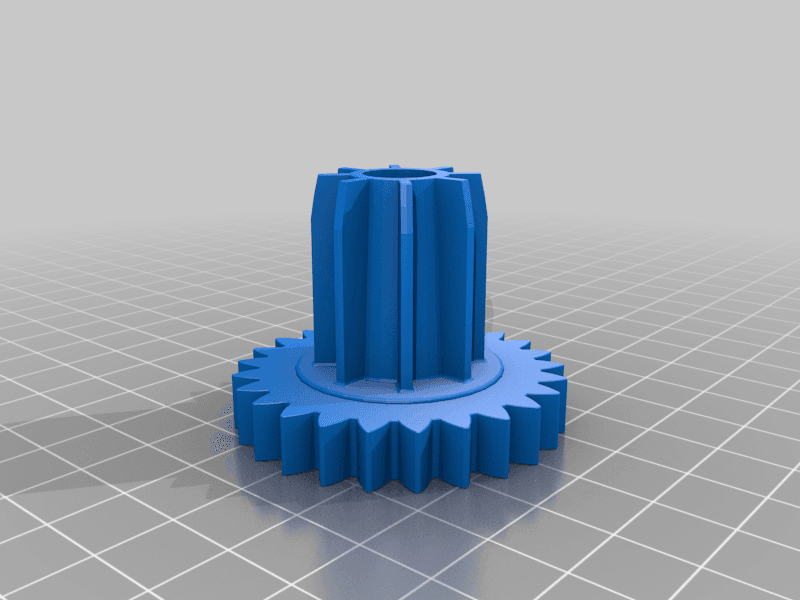

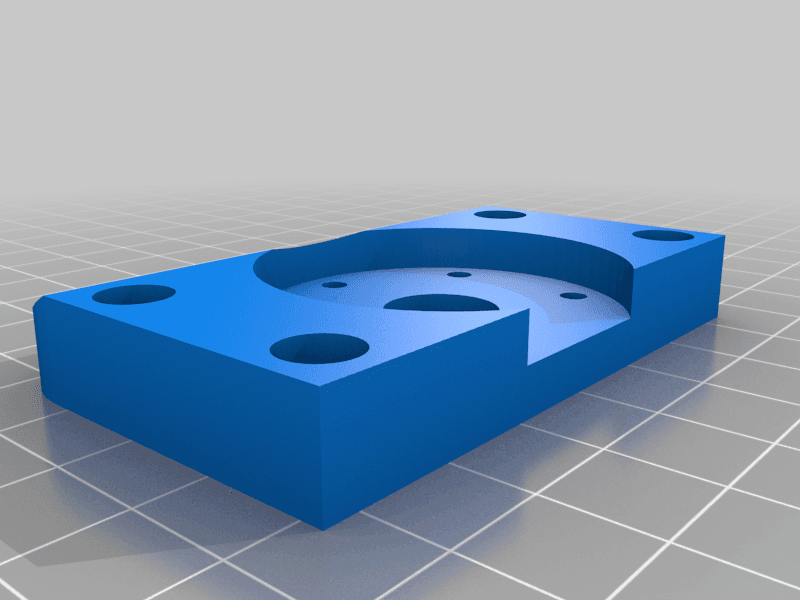

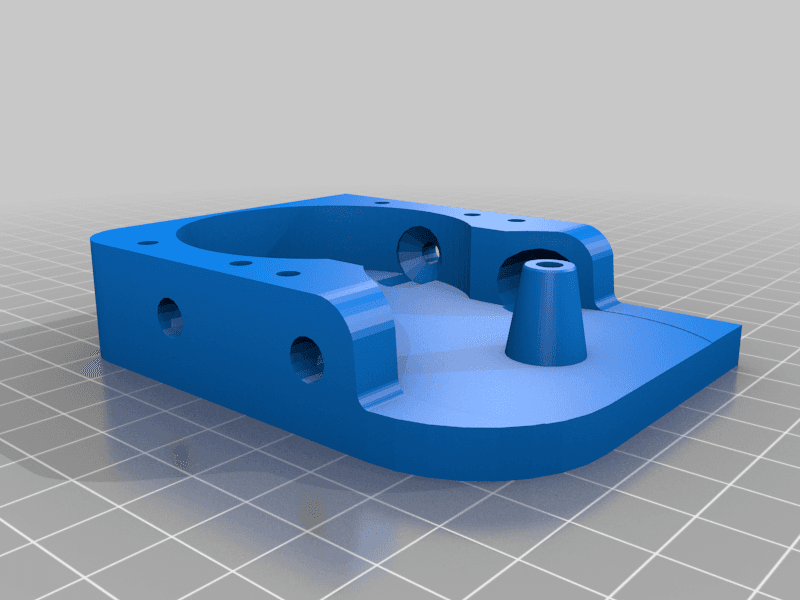

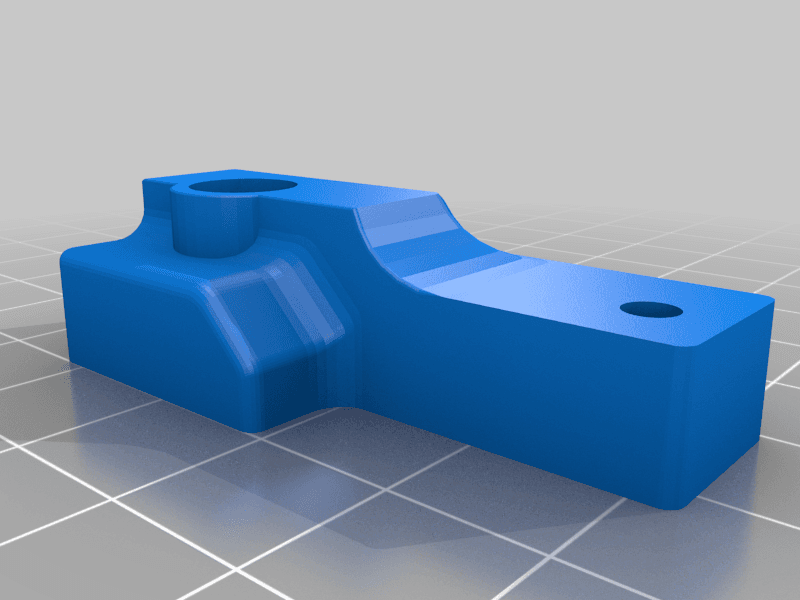

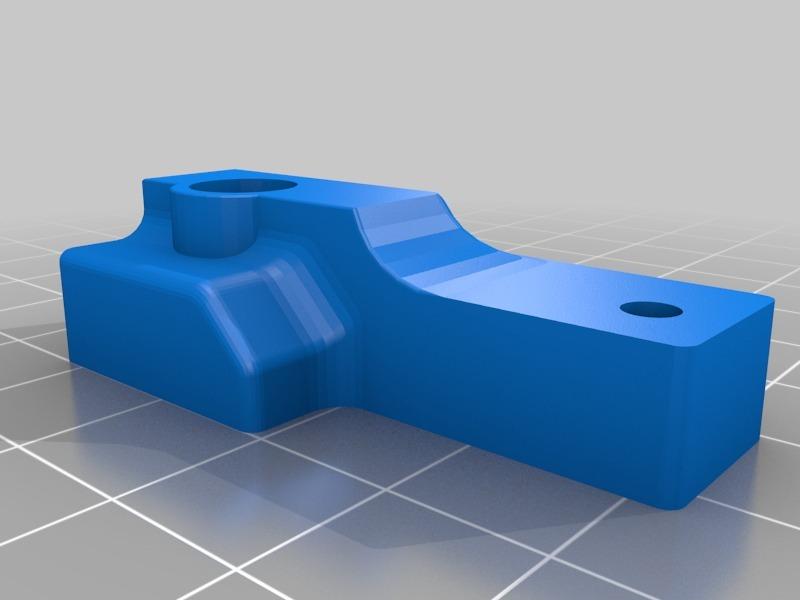

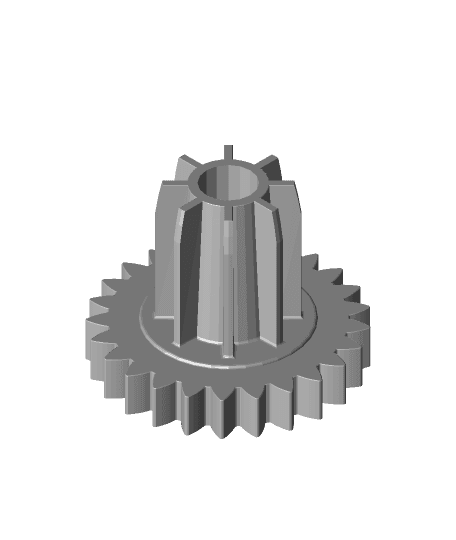

The motor plate is held on by four M3 bolts (hex-head) going into four captive M3 nuts in the base. First, screw the motor to the plate with three or more M3 screws, then bolt the entire plate onto the frame (pushing on the motor gear first).

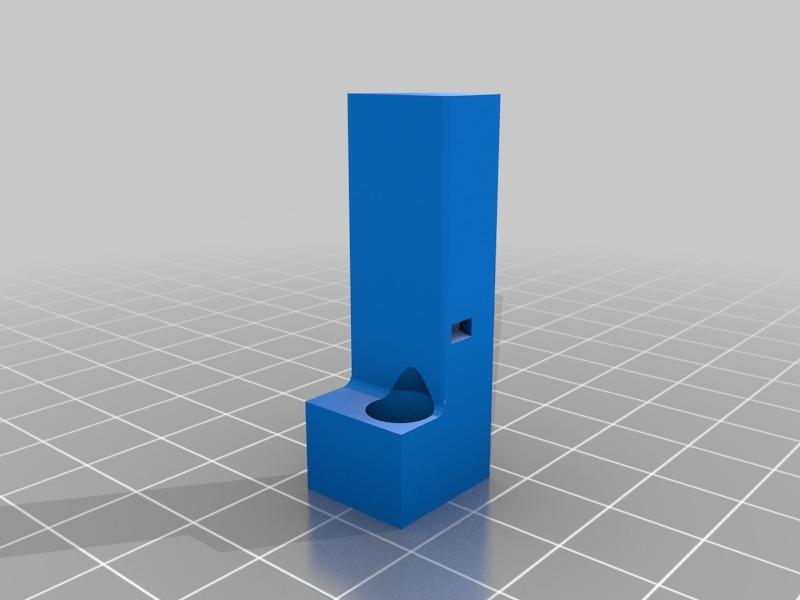

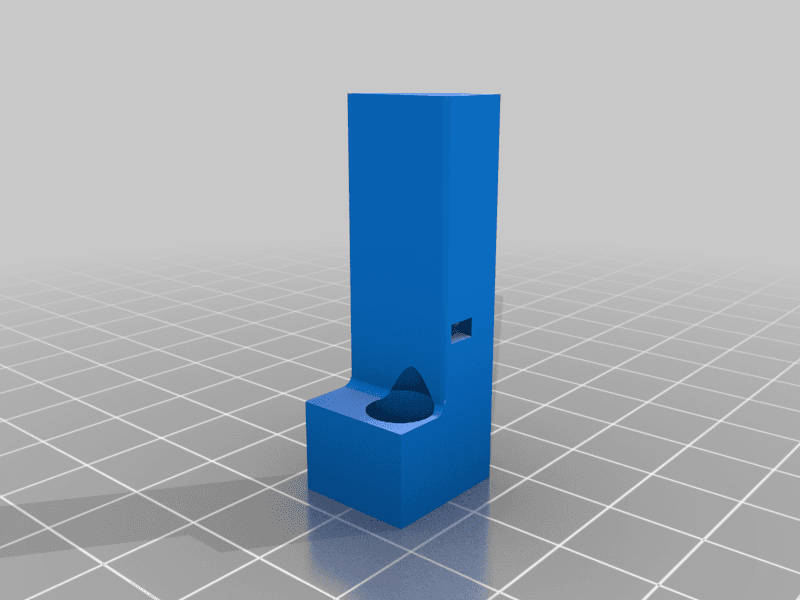

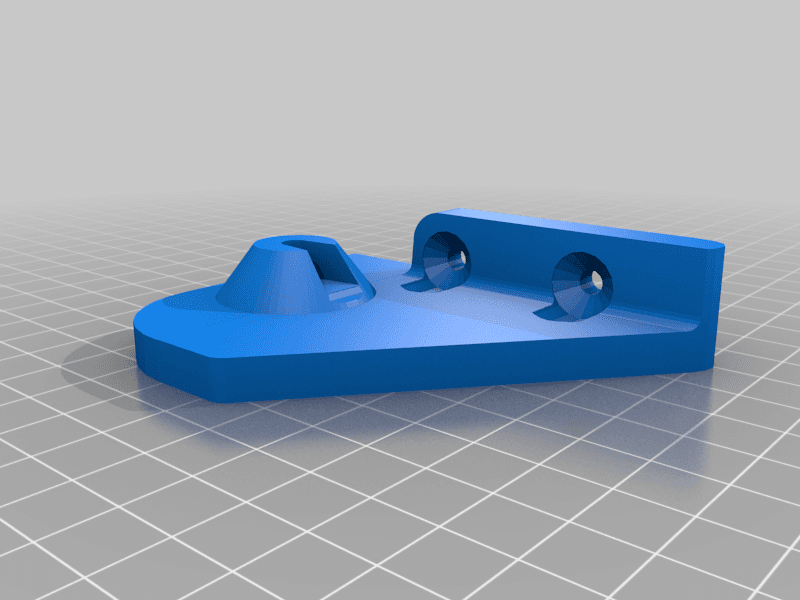

The free end of the blind uses the existing fitting for strength, but it should be straightforward to model a new one. If so, I'd recommend increasing the slot width and the diameter of the stalk.

I'm connecting this arrangement via a cheap IBT-2 H-bridge board to an Onion Omega board currently being used to control the "GidTech Blind-Tilt-A-Tron 2000™" -- http://www.thingiverse.com/thing:1051809 -- wooden slatted blind controller; it communicates via MQTT to a custom Internet of Things environment. Alternatively, the H-bridge could be connected to an Espruino, an Arduino, an ESP8266, or similar.

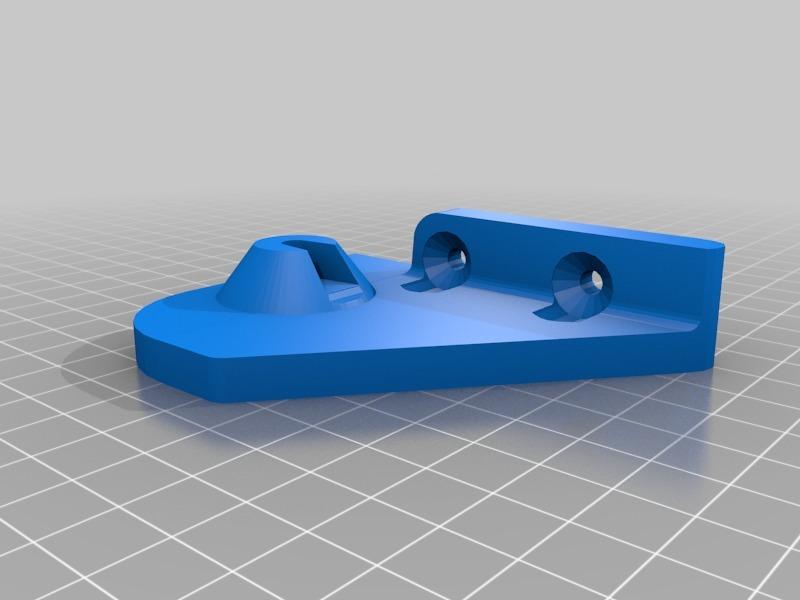

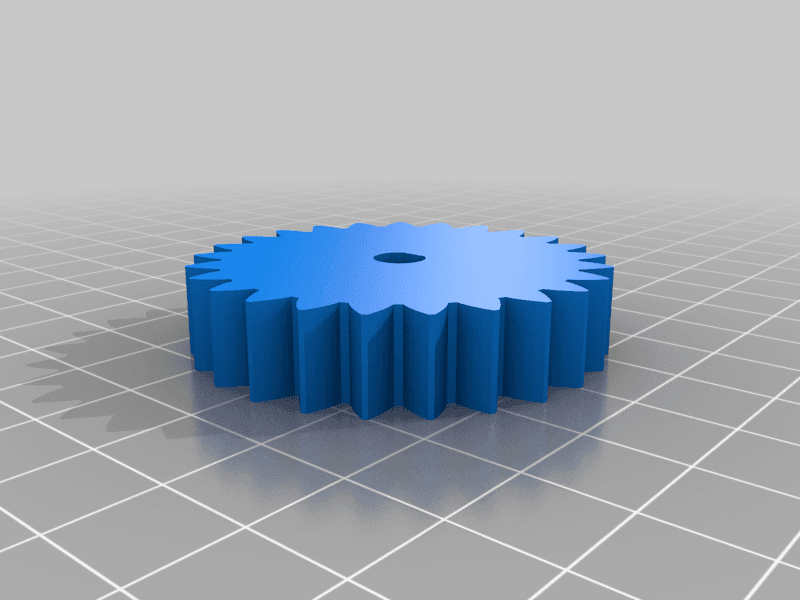

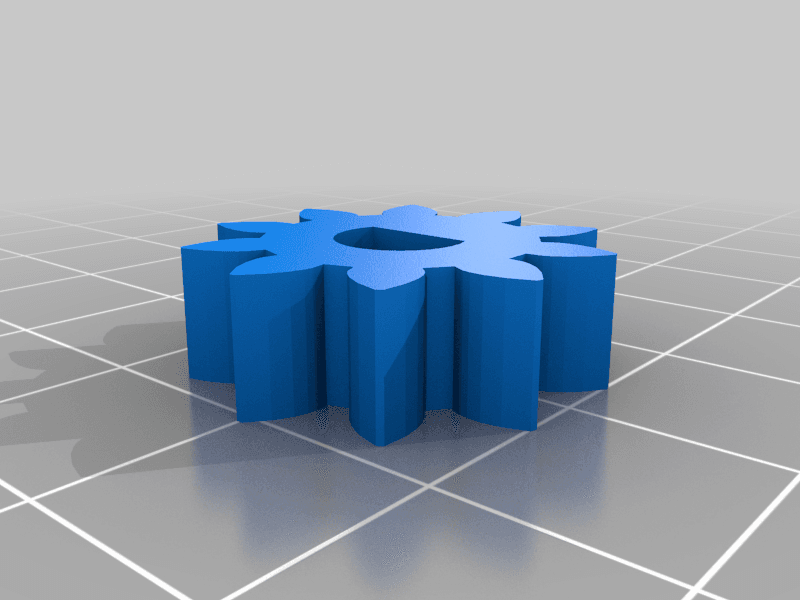

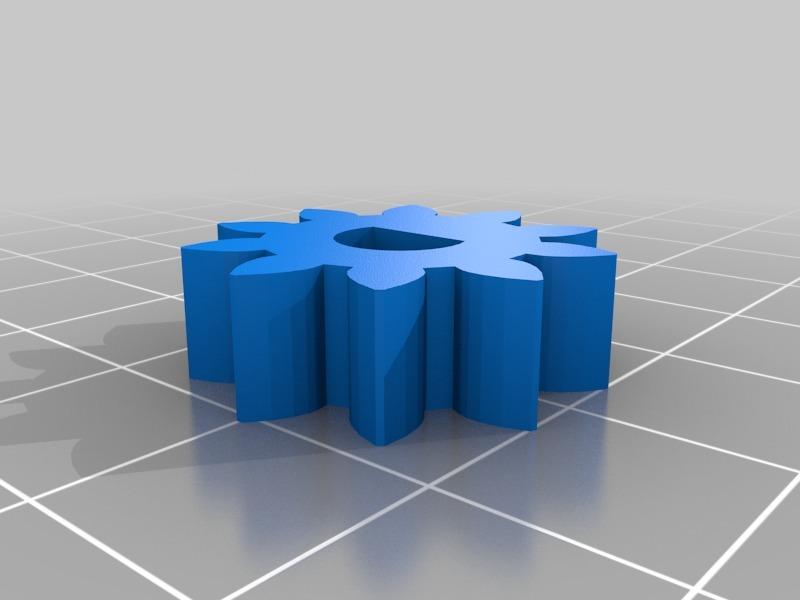

You could control the motor with simple up/down buttons or a DPDT rocker switch, or you can use the otherwise-unused "accessory port" holes to mount limit sensors. I've included a partially-developed mount for copper wire brushes to contact against conductive copper tape stuck to the blind; or Hall effect sensors to sense adhered neodymium magnets. However, my favoured approach is the included rotary encoder attachment and third gear wheel so a microcontroller can receive a stream of pulses to maintain blind position.