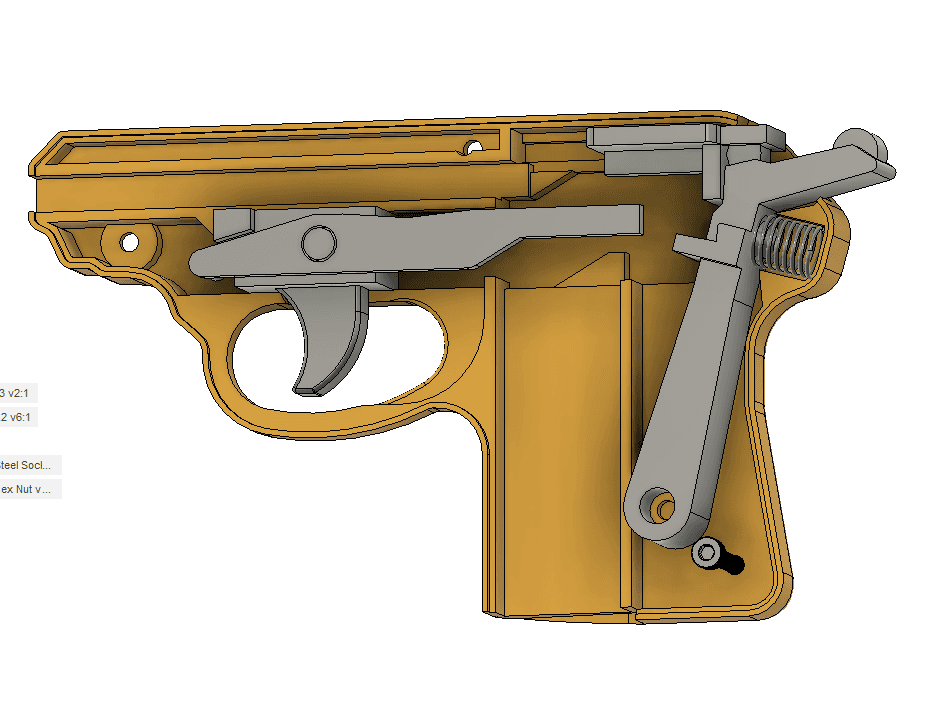

CANDY GAT - THE 3D PRINTABLE CANDY SHOOTER

THIS IS A CANDY DISPENSER AND NOT A WEAPON. THE ONLY BODILY HARM IT COULD DO IS IF YOU CHOKE ON THE CANDY OR PRINT IT IN BLACK AND POINT IT AT SOMEONE. PLEASE DONT..

Inspired by the original which is long discontinued - A challenge to myself to make a 3D printable version of the candy shooter.

After many months and a few spools of material I was able to create a version which does work reliably with almost no tuning needed. Print, assemble, and have (safe) fun.

Depending on your printer settings, you may need to spend some extra time ensuring the parts are deburred and free of any defects.

DO NOT PRINT IN BLACK, GRAY, OR ANYOTHER COLOR WHICH MAY CAUSE THIS TO APPEAR TO BE A REAL FIREARM. DO NOT USE IN PUBLIC. ADULT USE ONLY. DO NOT GIVE TO CHILDREN. DO NOT DISPLAY IN PUBLIC. Please don't get me put on the news for the wrong reasons. This is a toy but intended to be used responsibly by adults.

ADDITIONAL PARTS: There are additional parts which will be required for this to be functional:

- pez dispenser

- compression spring [I used a 3/8" (9.5mm) diameter x 51/64" (20.2mm) length]

- extension spring [13/64" (5.2mm) diameter x 37/64 (14.7mm) length]

- (3) M3 x 20mm hex socket screws

- (3) M3 nuts

I bought the springs from Home Depot https://www.homedepot.com/p/Everbilt-Spring-Assortment-Kit-84-Pack-13554/203133714

The screws can be bought at home depot too https://www.homedepot.com/p/Everbilt-M3-0-5-x-20-mm-Zinc-Plated-Steel-Socket-Cap-Recessed-Hex-Screw-3-per-Bag-803208/204281930

MODIFIACTION TO THE CANDY DISPENSER: Video -> https://youtube.com/shorts/INC2RlQcEgQ To make the candy "mag" you have to remove the top of the dispenser and cut the plastic "spring" off - level with the web of plastic the candies push against. It should end up about 9/32" (7mm) above the outer shell. You then need to cut a slot in that web about 3/16" (5mm) wide so the "sender" can pass through (which is 1/8" (3mm) wide)

TROUBLESHOOTING: "The trigger is not moving back and forth smoothly"

- Make sure the hammer and sender are moving freely when pulled back manually

- Make sure the printed parts are free of any extra material. Deburr the edges if needed.

- Look for any signs of something rubbing and address. I have noticed that sometimes the trigger block can dig into the track it travels in. If that happens, add a small chamfer on the trigger where it is rubbing. It may be helpful to use a small amount of food safe lubricant to the top of the trigger block.

- Make sure the front of the TrigMech_Left and TrigMech_Right are going all the way together (no gap in the front bar)

"The trigger is moving all the way back but it is not firing at the end of the travel"

- Make sure there is no extra material on the "ears" of the hammer.

- Make sure the corners of those features are smooth and have nice edges. Over or under extrusion may ruin the timing of the trigger release

"Everything is moving as it should but why is the trigger pull so hard?"

- Well it is a bit of a balancing act to make sure it's not too hard to pull the trigger and yet make the candies fling out with some force. I think the spring I chose is a good balance after much testing but you are welcome to use a weaker spring. You could even cut a couple coils out of the existing spring to reduce the force needed but try to stretch it out a bit so it doesn't fall out of place

"Something else is wrong"

- Please contact me with any issues. I'm happy to help you get it working properly. If necessary, I'll make changes to the 3D model in a timely fashion and update them on this page

3D PRINTING SETTINGS I printed out of PLA at .2mm layer height and 75% infill.

Supports are required for the shell and hammer

Private use only please. See license for more details. If interested in selling prints of this, please contact me