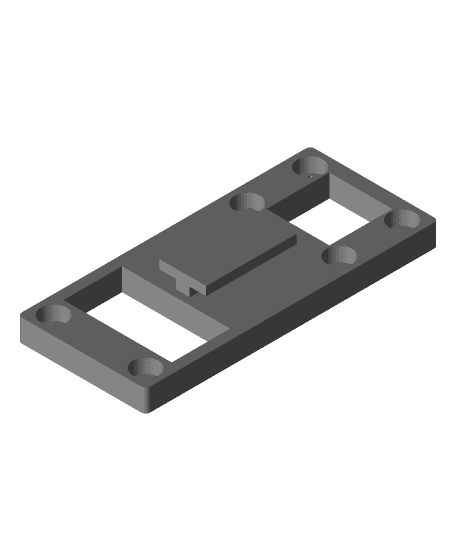

I had a need to mount my Big Tree Tech Smart filament sensor on the upper extrusion for my ender 3. I hope this is useful for you too.

-

Make sure your printer has the dimensional accuracy required to print this thing. If the t slot part don't fit then I suggest you tune your printer. Teaching tech has a whole website dedicated to this.

-

With Version 2 I ditched the tinkercad abomonation I created last time. This time all pars were designed by me from the ground up. I recently made a V Groove Mount for the Smart filament sensor and became very familial with this things dimensions. The tolderances in this new version are much tighter and the device should move around even less than before and be easier to print.

-

You should print this as shown in the cura image or as shown in the 3mf file. You should set supports tom Standard, everywhere and Support Density should be around 5%. You should be able to scrape the support material out with a snall flathead scre driver bit like I did so you want there to be very little support material.

-

*The CAD files are included, but please do me a favor and don't sell my work, V2 is all original. Instead, if you like it send me a couple bucks for filament

-

If you are having constant filament runout alerts, Try setting the filament runout distance to a higher number, like 25. This is happening because the sensor only detects when filament is pulled through, if there is slack between the output of the sensor and the input of the extruder then you will get a false alarm. Raising the runout distance gives the extruder more time to take up the slack that accumulates when the hot-end moves along the X axis.

Marlin: define FILAMENT_RUNOUT_DISTANCE_MM 25

Bigtreetech TFT fil_runout_distance:25

Print Settings- Use a raft, for the lov of god, use a raft.

- I printed at standard quality (.2) on a .4 nozzle using a Phaetus Dragon with a knockoff BMG extruder + My other smart filament sensor V groove mount case

- I highly suggest using a raft. Seriously, you should be using a raft every time. In case no one told you.

- You can use a very fine flathead screwdriver (about 2mm wide) to scrape out the supports, as long as the support density is less than 5% or so.

- I used fusion 360 for the whole thing.

- I recently became familial with the drawings for the Ender itself and am working on an SKR + RRF case at the moment, so I thought I would revisit this old project evenm though I dont use this mount anymore I use this one