Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:5155154.

Updates2021-12-05 Uploaded a new cover with the right leg moved 2mm to the right for more even access to the hotend and to prevent the right duct from contact with a V6 heater block sock

DescriptionWhen you just need even more cooling.

This is an evolution of my Adder cover and ducts which can be found here: https://www.thingiverse.com/thing:5101148

It is worth mentioning that the efficient airflow means that a lot of air gets pushed through the ducts with 2 5015 fans. For most prints you will probably only want to use 50% fan speed in your slicer. 100% is for large prints with a wide nozzle printing at speed. If you have the fan speed too high you risk poor layer adhesion and sometimes rapid cooling of the heater block which can force the printer to abort with a cooling warning.

I put this together to help with printing on the Creality CR-6 SE with a 0.8mm nozzle and a high flow hotend. This has helped cool large PLA parts printing at high speed.

It has been tested up to 185C while printing PolyCarbonate (PC) filament.

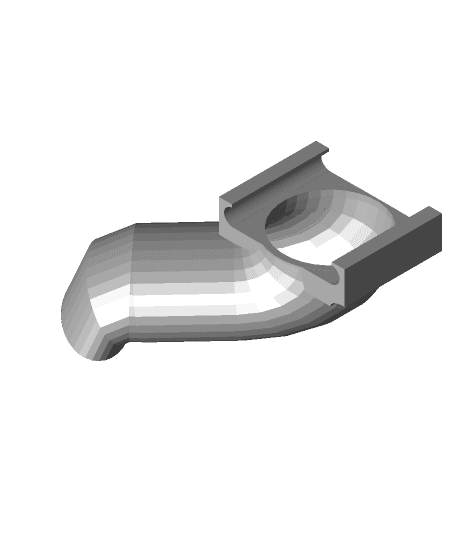

The cover is designed to take two 5010 fans. It also has a removable ducts if you want to add your own duct designs, lower the duct height (e.g. for a Volcano hotend) or to replace an existing duct if it breaks or warps.

The main cover can be printed in PLA or PETG as it's not coming that close to a high heat source. I printed it in PLA as PETG is a bit too flexible. The ducts need to be printed in a heat tolerant filament, e.g. PLA HT (High Temp), ABS, ASA, PC, etc.

Unlike other covers, you can still use the stock hotend LED (if you find the blue light useful).

The design caters for hotends with either a 3010 or a 4010/4020 heatsink cooling fan.

It has been tested on a stock hotend as well as a Phaetus Dragon Hotend (E3D v6 heater block).

The tolerances for the duct mounts are quite tight, so some sanding/filing might be necessary for a good fit and to avoid damage when fitting.

All the parts should be printed with supports touching build plate only, at the orientation show in the image listed. The main cover can be printed upright for a nicer surface finish. However, printing it upside down with supports makes for a much quicker print with the same strength, but with a poorer finish due to the supports.

With the dual 5015 fans you will need to splice or make a cable that splits the output from a single to a double JST-XH connector for both fans to connect to the single socket on the daughter board.

Note: When fitting, you need to screw on the cover to the printer before fitting the fan(s) so that you can access the left mounting screw.