Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:4740454.

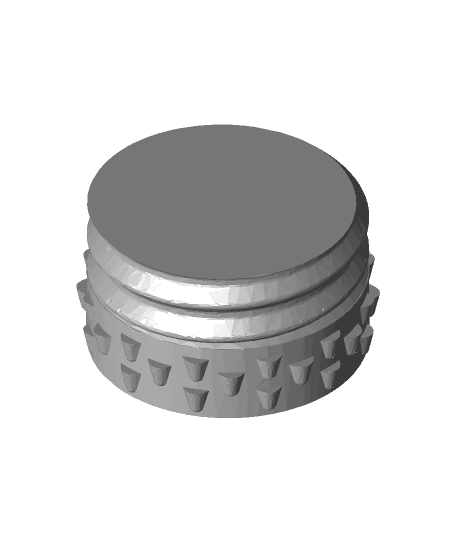

This is a mashup of TempusEdaxRerum's clever dimpled vase-made desiccant cup, and mitchell_cj's equally ingenious screw-together model. I found the dimple holes on the former to be a bit too big, and my cheap desiccant beads would occasionally fall out. I also wasn't a fan of the snap-on lid. The latter only had air holes on the top and bottom. Neither had a particularly efficient (printing-wise) base hole pattern. So I combined the best features of each and added my own slotted bottom. The slots are spaced to slice perfectly with a 0.6mm line width.

Thingiverse is being thingiverse and not allowing my to credit both sources right now for some reason, so here's direct links:

https://www.thingiverse.com/thing:2538528 https://www.thingiverse.com/thing:2843807

Slicing settings:

Vase mode, obviously. It's called "spiralize outer contour" in Cura. Set your line width to 0.6, your layer height to 0.28 (or thereabouts, depending on your ideal Z increment), and your flow rate to 140-150%. Yes, this is overextruding, but that's what you want in a sturdy vase mode print. You'll probably want to crank up your print head temp a bit to compensate for pushing that much filament (I went to 190C for PLA that normally prints at 180C). Print slow - with my CR10 knockoff I printed at 40mm/s with 15mm/s for the first layer. 2 bottom layers is sufficient, but I print 3 just to give it a bit of extra rigidity. Vase mode requires top layers be set to 0, and wall line count is irrelevant.

Print one copy at 100% size, then print another at 105% size. They should screw together perfectly.

Each half uses about 8g (2.5m) of filament and should only take 15-20min to print. Fits in any most spool holes, and it's a great way to use up that last little bit of filament from a spool.

EDIT: I found that one of my spools (TTYT3D silk) was just a bit too small to fit the 105% half of the cup. I logged in to make a note of this, and saw that user Ashnak had already discovered this issue the hard way. Sorry.

At 105%, the larger half is just a hair under 56mm in diameter. If you have a spool with a hole smaller than that, you'll have to scale down the model to fit. The key is to have a 5% differential between the halves. So just scale down the big half until it fits your spool, and then print the small half 5% smaller than that. For my TTYT3D spool, I printed the two halves at 95% and 100% and it fit.