Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:1357140.

Update: 25/05/2021

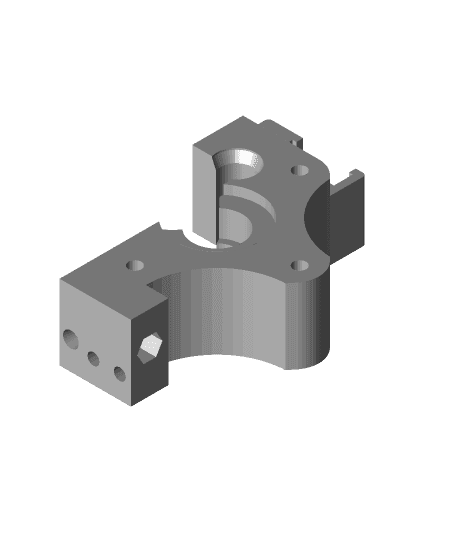

-Hinged Extruder body 1.2 filament path after drive gear tapered for easier filament insertion -Fitting block 1.2 alignment correction

Update: 30/10/2020

New Extruder with Hinged Lever for overall better reliability and ease of use. Also new knob with thicker hub.

Hinged Extruder body.stl lever.stl manual feed knob.stl

Hinged Extruder.scad for customization

NOTE: STL FILE INCLUDED IS FOR EXTRUDER GEAR DRIVE WITH 8MM OD (gear_diameter=8;)

PLEASE CHANGE THE VALUE in the first variable in the SCAD file >> gear_diameter if you have a bigger drive gear.

gear_diameter= [your gear OD size];

Update: 3/17/2016 Added Counterweight Suspension System for the Flying Extruder to minimize additional load on the stepper motors. This makes the whole extruder virtually weightless. Please print new_plate. This moves the suspension point at the center of gravity of the motor and is adjustable. Check out new files and video. Thanks!

You will need a slightly longer bowden tube since you will raise the extruder. Get rid of the old knob and replace it with a M3x25mm screw and washer and cut a piece of rubber tubing to act as a spring to push the lever on to the filament.

Flying Extruder kit for the Kossel Mini. Can be used with any delta as well. See video below to see it in action.

I would like to give credit to WASProject of Italy for their Suspended Bowden from which I derived the design for this Flying Extruder. http://www.wasproject.it/w/bowden-sospeso-di-wasproject/

DO NOT print plug.stl It is used for the SCAD file, for "tapping" a 1/8 BSPT thread. If your fitting is different, use this https://www.thingiverse.com/thing:227192 to make a different plug.

SCAD files are included for your customization. (Nema 17.scad file is from Johann's Kossel Mini files)

You'll need: M3 x 16mm screws for the nipples M3 x 35mm screw for idler adjust M3 flat washer to insert in slot at back of extruder body M3 nut to insert at bottom of back of extruder body (to mate with idler adjust screw) M3 x 24mm x 3 screws for mounting motor M3 x 12mm x 2 or similar course thread screws to fix plate to body Clear epoxy or CA to glue fitting block to body Bearing 16x5x5 for idler Bolt M5 x 16mm for idler hub (A simple 5mm dia x 20mm rod will also do. I used a 5mm rivet) 3/16" ID x 100mm x 3 rubber tubing for suspending the plate to the nipples

If you like it and find it useful, I'd appreciate a small tip. https://paypal.me/boksbox/1USD