Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:2024355.

** 20170228 : Attention -- Possible issue when in a hot environment ** I ran in a tolerance issue when printing ABS. The top part of the printer was around 50°C and the thermal expansion caused step skipping due to grinding between the stepper motor and the 2020-profile. I've added some extra room (2mm) between the stepper and the 2020-profile with a new front and back plate. Unless you only print PLA, I strongly recommend to use files FrontV2.STL and BackV2.STL !! Tested and works nicely now. See last picture for the added room between profile and stepper.

I made also a new TOPV2.STL for the cablechain mount. This one has, like the bottom piece, complete support for the bolts.

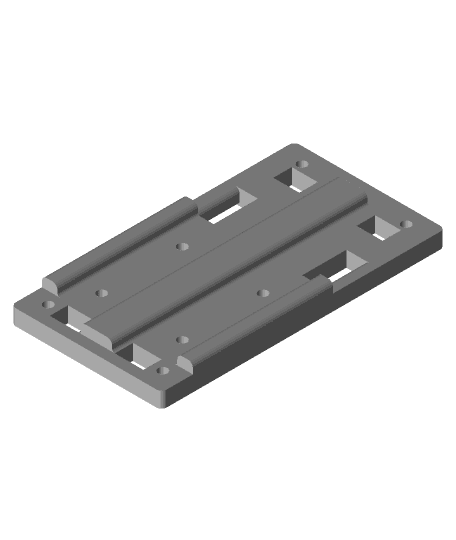

A redesigned header for the FT5. Push once to the tip of your hotend to the back/front to see what I mean with rigidity. Extra support for the bolts, extra ribs on front- and backside, higher bottom- and top part give extra rigidity to the header. Absolutely no play in Y-direction anymore. The top part has the nylocks integrated. Nylocks fit quite tight (you don't want to loose them when everything is mounted) : use a bolt to pull them completely into their seat. (see pictures) Bottom part has an integrated support for mounting a partcooler. If you have a Titan/Volcano you could use the design from the pictures Bolts to fix top part on slider are M3/12mm

Mounting is quite straightforward.

Tip : Use 3d-Tool to have a detailed look on this thing