This model is restricted by licensing terms.

View license.

Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:5388912.

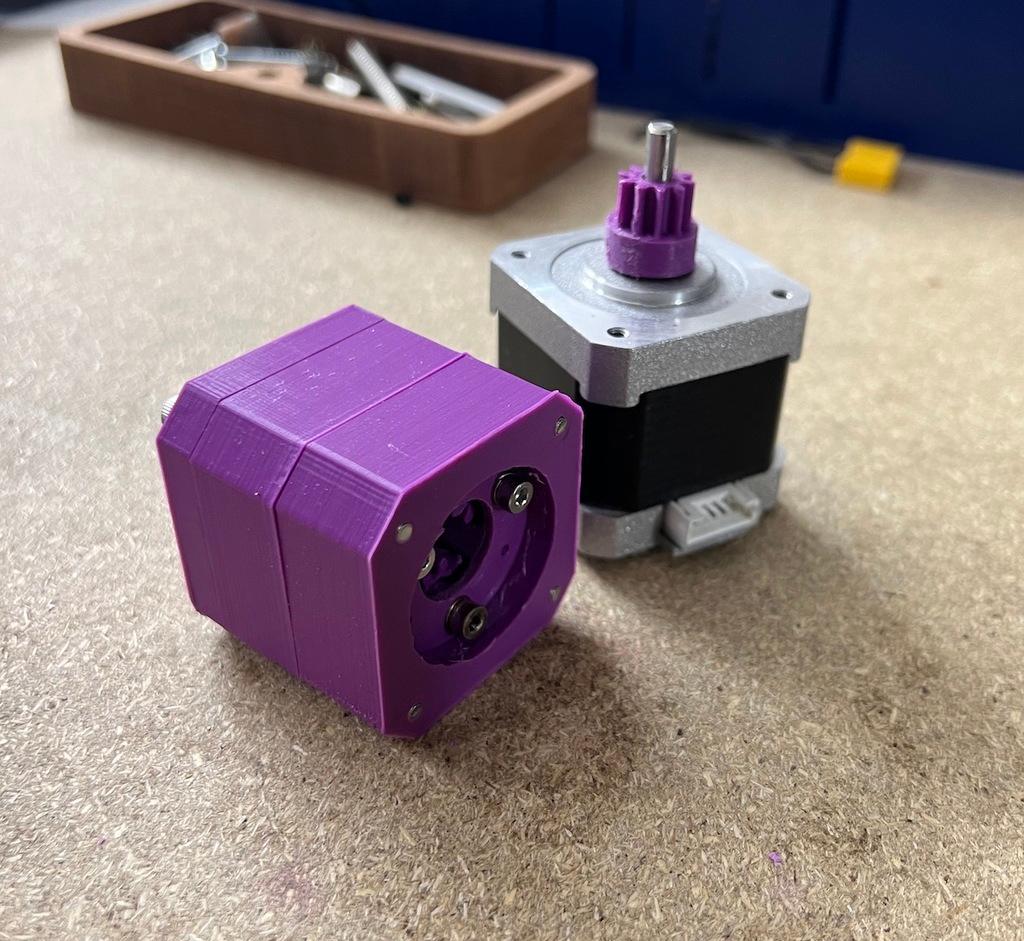

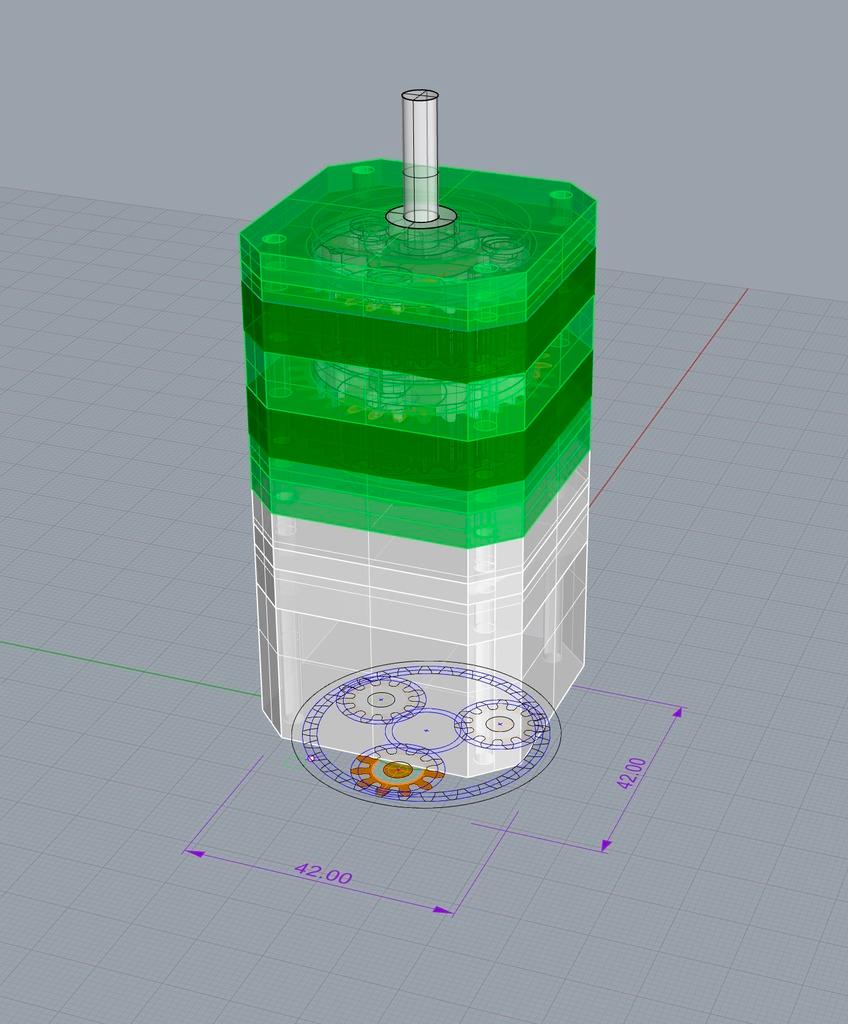

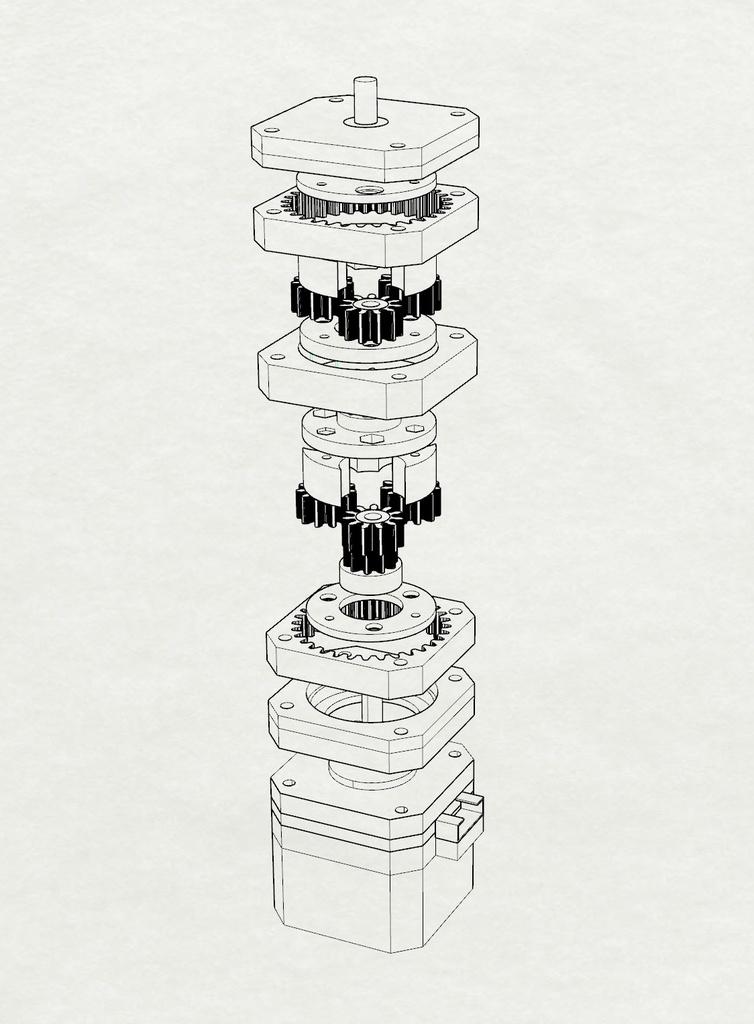

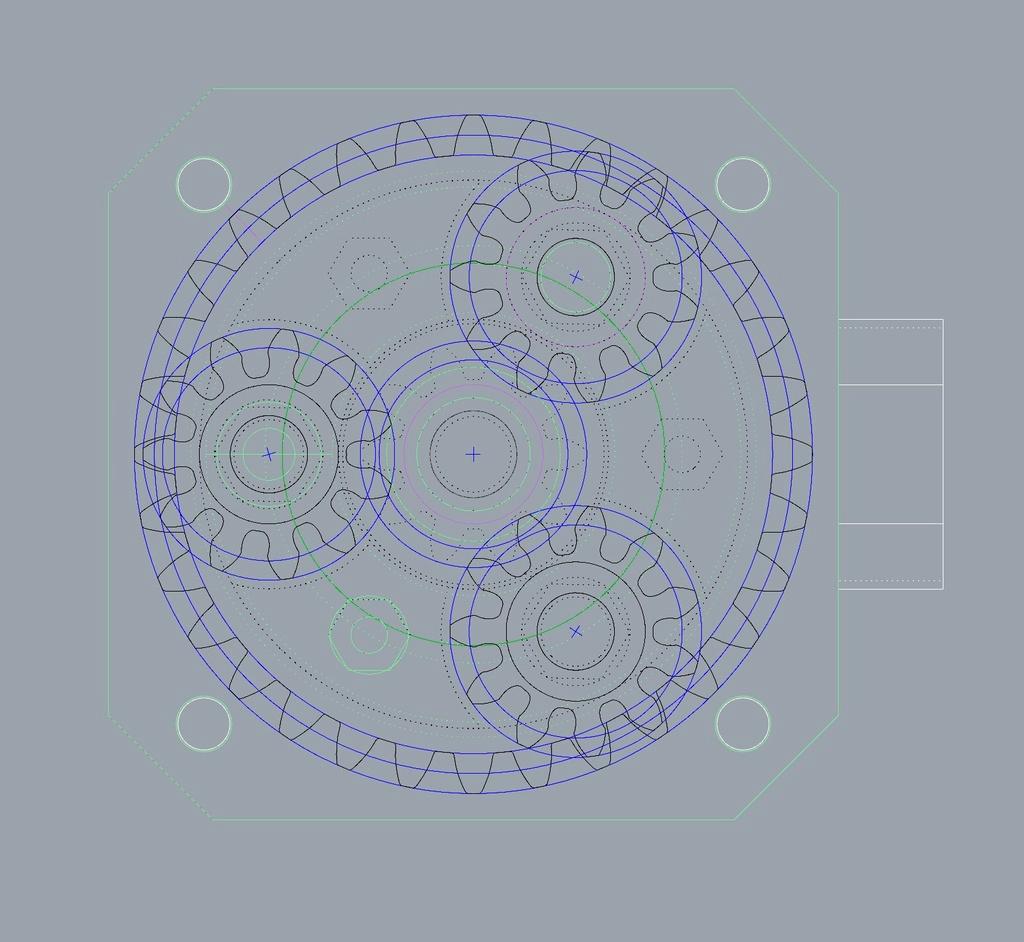

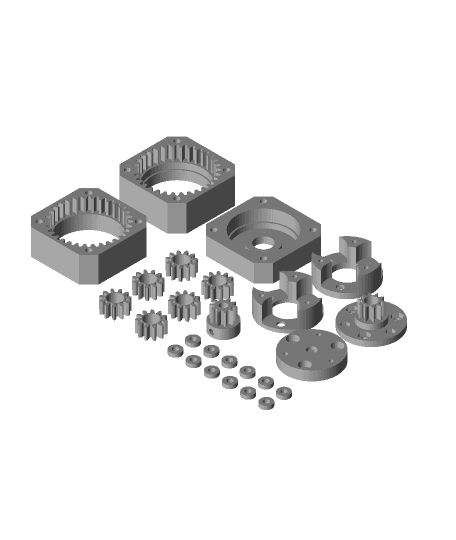

Here’s a design for a 2-stage planetary gearbox with ~ 10:1 reduction.

It’s around 40mm tall and fits nicely on top of the Nema17 stepper motor, joined with some (>40mm) M3 bolts.

The gearbox works just fine under the load and provides a decent torque, but I haven’t stress-tested the gearbox yet. Intuition suggests that thinner parts of planet gears should give up first, and therefore a smaller bearing would be more optimal (more in ‘Todo’).

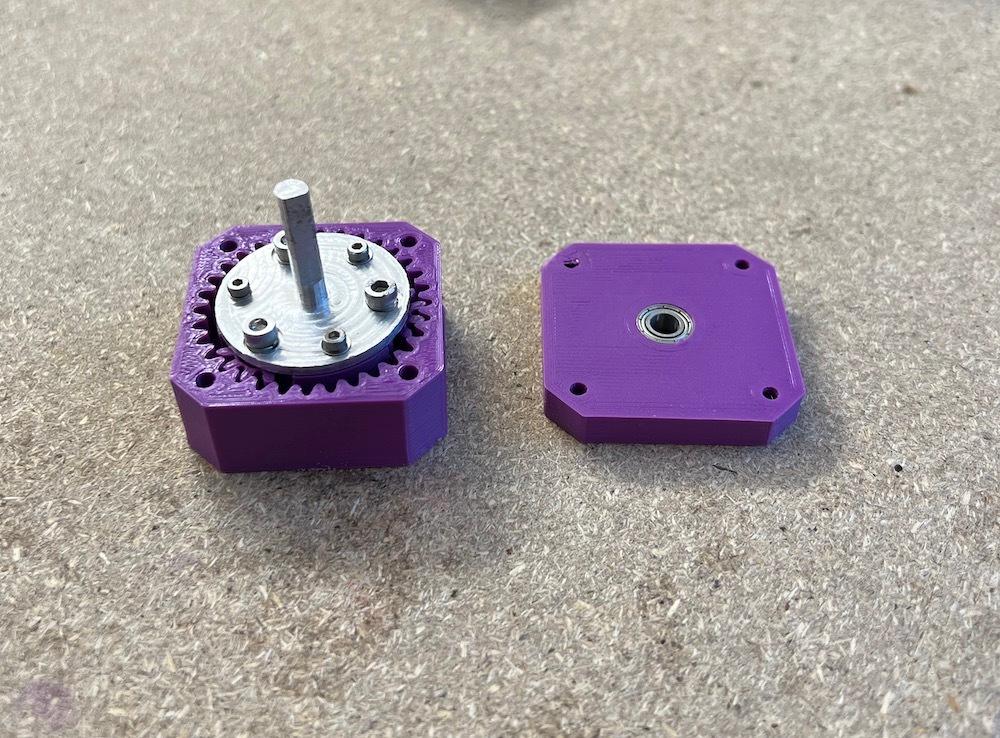

There are two versions of the gearbox top cover depending on whether you’ll be using a milled shaft or an M5 bolt for the output.

Don’t hesitate to write suggestions and ask questions!

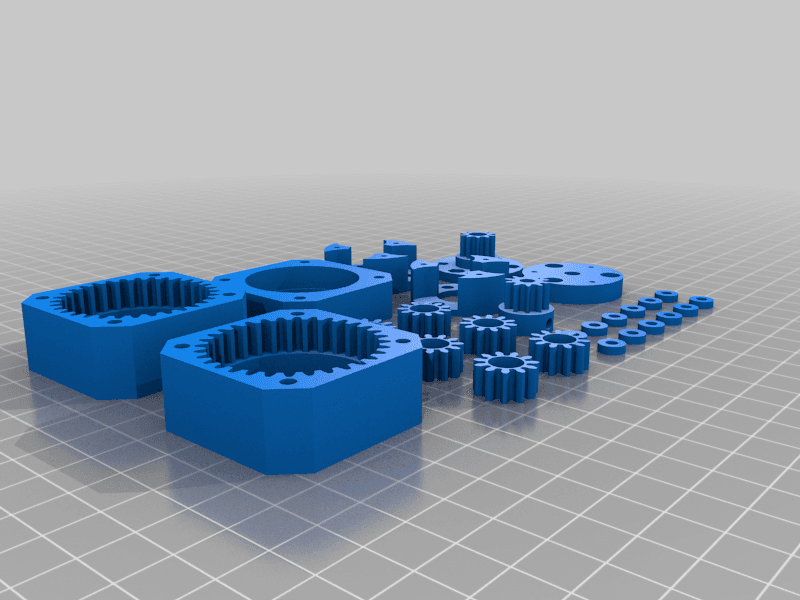

Parts:

- M3 bolts and nuts

- M2 bolts and nuts

- M2, M3 washers

- MR 105 ZZ bearing (for output shaft)

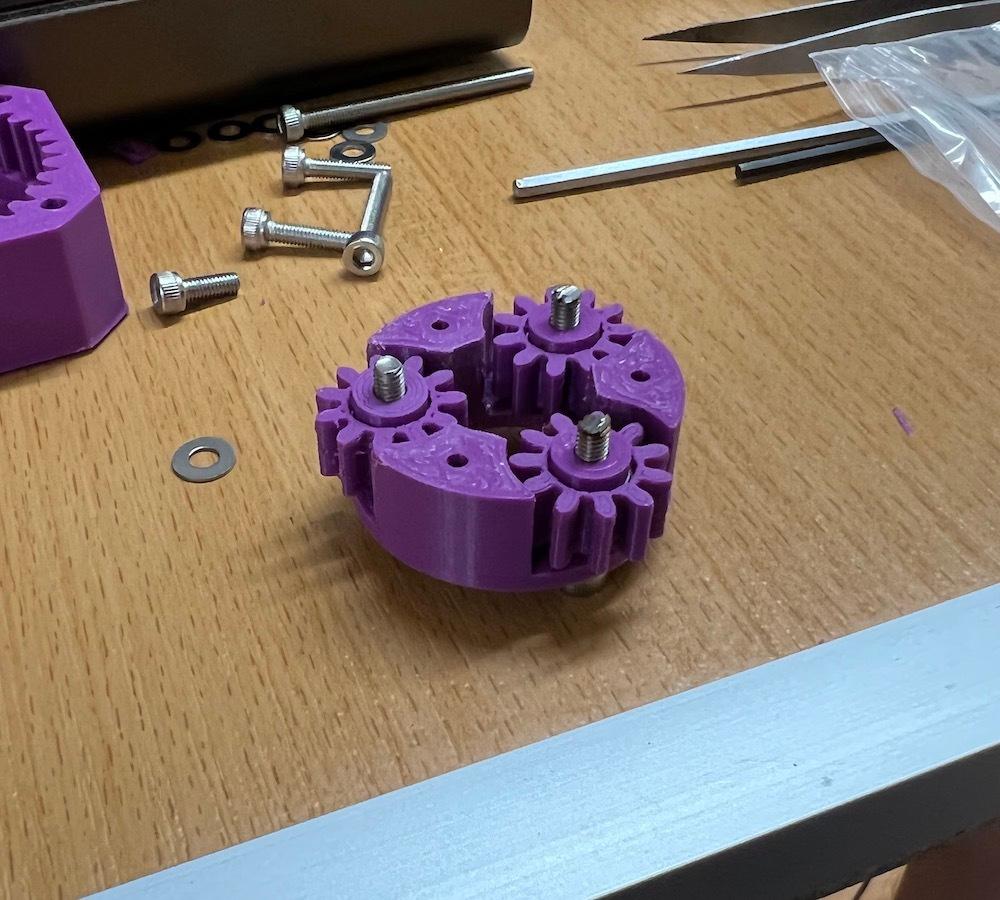

- 6x 693ZZ bearing

- 2x M3 5.35-5.5mm wide (and 1.8-2.0mm thick) square insert

- M3 grub screw

- Loads of grease

Assembly:

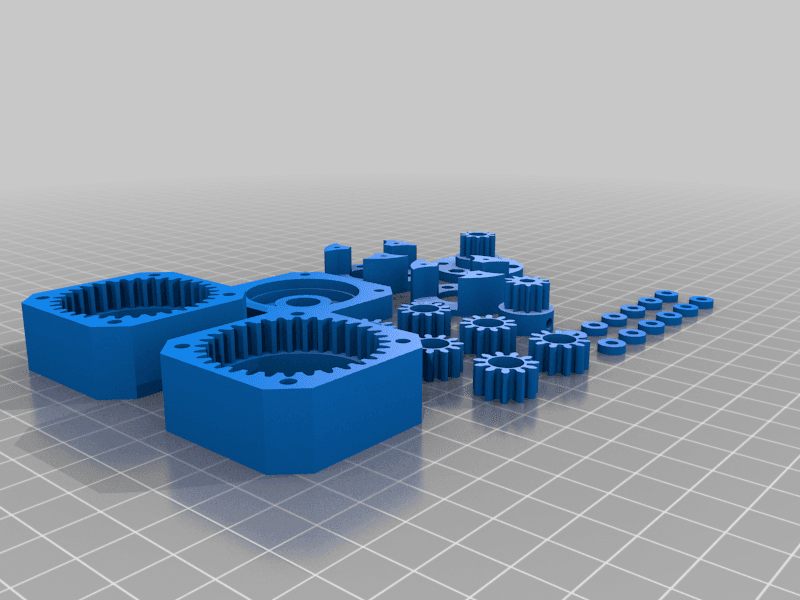

- Print the parts

- Adjust the height of the first sun gear on the stepper motor and fasten it using square inserts and grub screws

- Press-fit MR 105 ZZ bearing into the top part

- Gently press fit (heating up the part slightly may help) 693ZZ bearings into planet gears.

- Join planets and spacers using M3 and M2 bolts (adding washers in-between bearings and enclosure.

- Join everything with ring gear/case using M3 bolts adding a lot of grease.

9 Likes90 DownloadsSeptember 8, 2022

9 Likes90 DownloadsSeptember 8, 2022

This model is restricted by licensing terms.

View license.