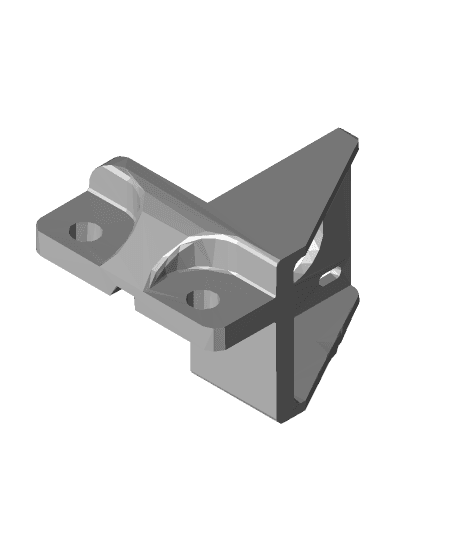

Just Modded a little for the tronxy-xy2 I have, maybe it works with xy3 and xy2 pro (please comment if it does or does not)

ORIGINAL POST: ***Update- I'm re-releasing this under the GPL and including the source files. This last model has a few small improvements as well. This part was modeled in SolidWorks2018. Thank you for all the interest!

Long bowden tubes suck! This was even more apparent after installing a volcano clone heater block on my printer. You need precise control of the filament to keep blobbing in check.

Try this experiment- print out one of the many manual extruder knobs here on Thingiverse and install it on your extruder. Make sure the filament is fully inserted in your nozzle, and cool down your hot end. Once it is cool and the filament is fully fused into your hot end, turn the extruder knob back and forth and see how much the filament can move at the extruder with no movement at the hot end. The longer your bowden tube, the worse this is.

After looking through Thingiverse for a decent direct drive conversion for my CR-10 and not finding anything I liked, I decided to model my own. This fits on a stock CR-10 using the original style hot end (I am using the Micro Swiss all metal hot end).

My design goals were- Cost as near to ZERO dollars as possible Easy and clean installation A strong and solid mount Clear view of the hot end during printing

To those with concerns about adding mass to the X axis carriage- I say this: On an i3 style printer, It is irrelevant! Even with the big full size Nema 17 motor on the X carriage, it still weighs less than the y-axis- especially on a big printer like a CR-10. For comparison, my complete x-axis carriage assembly is 559g, a CR-10 glass plate alone is 1kg. Once you add in the heat bed, y carriage, etc, it's easily 2kg. And to make matters worse, the bigger your print, the more mass your y axis gets. Last I checked Cura 4.0 doesn't offer separate X and Y speed/acceleration/jerk setting, and definitely doesn't scale settings as the print increases in mass. If you are a speed junky, get a core-xy or delta printer.

Print Settings Printer: Tronxy XY-2

Rafts: No

Supports: Yes

Resolution: 200

Infill: 20

Filament brand: PolyMaker

Filament material: ABS, ASA, PETG, Nylon

Notes: If you print in PLA, with time the print will start to deform with the motor heat, don't make that mistake