(V1) For BIQU B1 - DIY Enclosure - Remix of Prusa's IKEA Lack Enclosure - with extra doors (opening on 3 sides)

byDesign8Studio.comModel originally uploaded to Thingiverse at https://www.thingiverse.com/thing:5137500.

Heads up! This is v1. A new, improved "v2" is NOW AVAILABLE!A new, improved "v2" of this enclsoure has been developed. Get it here: https://www.thingiverse.com/thing:5166976

If you're planning to make this, check out the discussion in comments linked right here: https://www.thingiverse.com/thing:5137500/comments#comment-6269801

I am a big fan of the BIQU B1. Of the seven 3D printers I currently own, four are B1's, and I have a BIQU B1 SE Plus on order. As you may know, a B1 is too tall to fit in the Prusa designed IKEA Lack enclosure (version 1) and their version 2 (which needs more height / headroom because of their multi-material add-on) costs a whopping 200 hours of print time because they decided to gain the extra headroom by printing plastic. I thought, "The IKEA Lack tables are only $9.99. I'll use an extra set of legs (turned side ways) to get the extra height." In short, it works, and the resulting enclosure holds a BIQU B1 nicely!

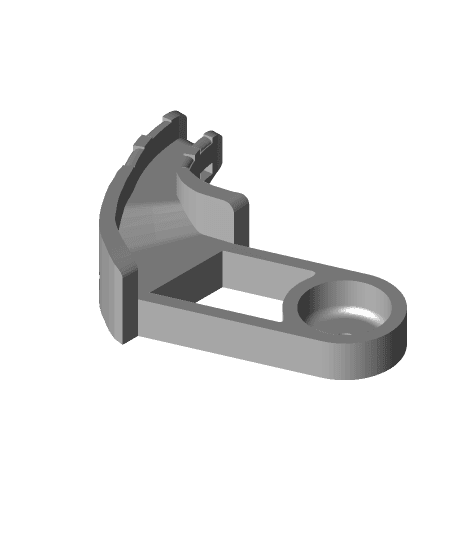

One minor caveat: just as many using the Prusa enclosure have had to print a new design of "heater bed wire strain relief part" with a 90 degree bend, in order to keep the heater bed wires from bumping the back pane of acrylic, this design also calls for that, and the good news is that my remix here already includes a part custom designed just for the BIQU B1. It's a drop-in replacement. Just use three zip ties to secure your heater bed wiring into the new part.

So, without further ado, here is...

DIY Lack table enclosure for BIQU B1 ** PARTS FOR PRINTING**Just as with the Prusa design, most of the printed parts are organized into sheets of multiple parts that are all designed to fit on the print bed of a BIQU B1. Those sheets are:

Bottom-Corners.stl Door-Knob-(x3)-and-Cable-Clips-(x10).stl Top-Corners.stl Top-Extenders.stl

Additional parts that are not ganged up on a sheet with others:

BIQU-B1-ac-heater-wire-redirect-strain-relief-bracket.stl

(The main reason the strain relief part is by itself, is so you can more easily print it in PETG, which I did, and advise you do, because of its exposure to heat from the print bed.)

ASSEMBLY TIPSAt the head of each corner, one "Top-Extender" is to sit above one "Top-Corner" — and be careful to insert your hinge into the "Top-Corner" before you snap that little assembly together and bolt it to the underside of the Lack table's top, using a big #12 lag screw (4" length). This is all done first, while the top of the enclosure in face down on your assembly area.

Once the upside-down table top has all four corner assemblies bolted on, you should be able to attach not only the four vertical table legs, but also the four legs that get inserted horizontally (to gain the extra headroom needed for a B1). I recommend inserting the horizontal legs first. This is designed for a snug fit, so have a rubber mallet on hand in case a few love taps are needed. Use screws vertically to attach the horizontally used legs to the table top, and use screws to attach them to the corner assemblies. I used some common black drywall screws (of various appropriate lengths) to do this. I used the same kind of screws to attach the vertically used legs to the top corner assemblies.

Re. your 3mm (1/8") thick plexiglass panes, which are to be sized/cut exactly as with the Prusa version 1 Lack table (440mm x 440mm for any solid panes with no door, and two 220 mm x 440 mm panes for where doors are called for), the usual and advisable practice is to insert your plexiglass panes before tightening down your bottom corners.

Speaking of bottom corners: Since the BIQU B1's AC power cord is apparently thicker than on a Prusa, I tweaked the Prusa-designed cable opening in the one special "Bottom-Corner" by enlarging it. My goal for the modified opening was to accommodate LED wires in addition to the thick AC power cord.

HARDWARE NOTEFour long screws are called for, longer than any used in the Prusa design, because of accommodating the additional headroom. These need to be 4" long (#12 size in diameter). An affordable way to source what you need is to buy lag screws from your local hardware / home improvement store. My design enlarged and deepened the "countersink" opening in the printed plastic part so that not only can the thicker hex head of a lag screw be fully countersunk, but also a socket head should fit in there around it to ratchet tighten the hex screw down.

THE BETTER TO SEE YOU WITH - L.E.D. NOTESAmong the advantages of using the additional set of table legs to gain the needed extra headroom, is that those legs provide a great place to attach LED lights. I like this placement better than on the underside of the top, because a continuous strip of lights can be installed without having to cut it into separate pieces (that would then need re-wired to stay attached to each other).

***So, here are several tips about LEDs: ***

If you have leftovers from some prior install of an LED strip of the kind that accepted color change commands from a controller with remote, and you just have some strip left with no more controller or remote, those leftovers can definitely be used for this kind of thing, and for me, I really just want nice bright white light in there, not a lot of crazy colors. I need to see! This is also a great way to make use of your litany of mysterious AC adapters laying around your house from who knows what that is no longer in use. Any AC adapter that matches the right voltage, for example if the LED light strip was 12v then the adapter should be 12v, and that is rated at or above the needed amps will work (any one that's rated for at or above 3 amps or more should be fine). Don't worry about it allowing higher amps. The AC adapter does not force the higher amps, it just offers them if the device wants to draw them. Trying to under power is where problems arise — the adapter can overheat. Don't try to power this many lights with only a 1 amp or 2 amp adapter! 5 amps or more is probably ideal, and 3 amps seems to work OK too. I've found that somewhere around 5'-7" of LED strip length is enough (about perfect) to get all the way around. I will try to post a video on it.

To get those leftover strands to burn all white, you want all three colors of RGB to be fully powered, and if it is a "warm white" version with an additional set of warm white LEDs, then that extra “line” needs full power too. To accomplish this (full power on all wires) you simply connect your "hot" (live or "+") wire to the "12v" wire on the lights (it will be labeled as such right on the LED strand, every few inches or so) and then connect the neutral or "-" wire to all the other leads. That gets full power to all, and you get white light.

I noticed the strips that don't say "warm white" tend to have a slight bluish tint that may or may not bother you. I did my first one with warm white, and liked it a lot, and then I wanted them all the same for consistency (I have 3 of my 4 BIQU B1’s in these and I’m building a 4th enclosure for the 4th B1), and I personally prefer the warm white kind. I think name brand is not as important as voltage and right color and it being decent quality. There's a bunch of name brands on Amazon, etc. A good kind to get, whether warm white or not, is “5050”!

Here are 2 listings of "warm white" 5050 LEDs that I bought and liked: https://www.amazon.com/gp/product/B084VPDDKN/ref=as_li_ss_tl?ie=UTF8&psc=1&linkCode=sl1&tag=httpdougjosne-20&linkId=7b75dbf4cc99a919d87892e9b44fcfdd&language=en_US https://www.amazon.com/gp/product/B084VPDDKN/ref=as_li_ss_tl?ie=UTF8&psc=1&linkCode=sl1&tag=httpdougjosne-20&linkId=7b75dbf4cc99a919d87892e9b44fcfdd&language=en_US

(note: both the above are out of stock, but it gives you an idea of what to look for.)

And here’s an example of regular 5050 LED: https://www.amazon.com/gp/product/B084VPDDKN/ref=as_li_ss_tl?ie=UTF8&psc=1&linkCode=sl1&tag=httpdougjosne-20&linkId=7b75dbf4cc99a919d87892e9b44fcfdd&language=en_US

Also, for connecting an AC adapter to a strand of leftover LED strip lighting, I found that having several tools and supplies made it super easy, with no soldering! Using clamping and/or crimping instead of soldering was just way, way better for me.

First, to make a connection that can be easily withdrawn and re-connected as needed, I ordered a bag of these beauties:

https://www.amazon.com/gp/product/B084VPDDKN/ref=as_li_ss_tl?ie=UTF8&psc=1&linkCode=sl1&tag=httpdougjosne-20&linkId=7b75dbf4cc99a919d87892e9b44fcfdd&language=en_US DC Power Connector 20 Pairs CCTV Power connectors 12V Male+Female 2.1x5.5MM DC Power Jack Plug Adapter Connector for CCTV Camera and LED Strip Light

…Those things are super handy to have!

Secondly, when I screw those (above) down onto the + and - wires, I'm tightening not onto bare wire, but rather leads that have ferrules crimped onto the wires. Much safer and better. For that I used this wonderful batch that comes with the amazing tool and a huge supply of different ferrules (barrels) for this job and lots of others:

https://www.amazon.com/gp/product/B084VPDDKN/ref=as_li_ss_tl?ie=UTF8&psc=1&linkCode=sl1&tag=httpdougjosne-20&linkId=7b75dbf4cc99a919d87892e9b44fcfdd&language=en_US Ferrule Crimping Tools Wire Pliers - 1800 PCS Wire Ferrules with Crimpers Pliers Kit for Electricians, Adjustable Ratchet Tools with Terminals Connectors AWG 28-7, 0.08-10mm²

…Also, being able to connect wires to wires without soldering, using the following either “permanent” or “removable” ways, is super handy:

First, for “removable” and with no crimper tool needed, these are awesome:

https://www.amazon.com/gp/product/B084VPDDKN/ref=as_li_ss_tl?ie=UTF8&psc=1&linkCode=sl1&tag=httpdougjosne-20&linkId=7b75dbf4cc99a919d87892e9b44fcfdd&language=en_US XHF Conductor Compact Connectors UL Certification Lever Connectors Nuts Electrical Connectors Wire Terminals for 2 Circuit Inline Splices 28-12 AWG (SPL-2, 50PCS)

And for “permanent” crimping to connect (without soldering) wire to wire, with use of a crimping too, these Butt Splice Crimp Connectors are super handy:

https://www.amazon.com/gp/product/B084VPDDKN/ref=as_li_ss_tl?ie=UTF8&psc=1&linkCode=sl1&tag=httpdougjosne-20&linkId=7b75dbf4cc99a919d87892e9b44fcfdd&language=en_US Butt Splice Crimp Connectors Insulated Electrical Straight Wire Terminal Connectors 10-22AWG

If you search Amazon for "LED clamps solderless" you find lots of affordable "clamp" / "clip" options to consider!

And finally, here’s a great wire stripper and crimper tool I am really liking:

https://www.amazon.com/gp/product/B084VPDDKN/ref=as_li_ss_tl?ie=UTF8&psc=1&linkCode=sl1&tag=httpdougjosne-20&linkId=7b75dbf4cc99a919d87892e9b44fcfdd&language=en_US Wire Stripper ,24-10 AW/ 34-3 Gauge/ 0.2-6 mm 8 Inch Self-adjusting Cutter Crimper Multi Pliers,With cutting,crimping,stripping function, Equipped with multi-function screwdriver tools

Oh, almost forgot, here are two listings of wire I bought and like - used on this and other projects:

*note: all links I post are affiliate links.

BUILD VOLUME Z HEIGHT REMAINS INTACTOne other note on the extra enclosure height needed to accommodate a B1: The B1's advertised build volume height is 270 mm. In my B1 inside this enclosure, I'm able to get 270 mm of Z height. So if you're concerned about it, I'm not experiencing any loss of build volume height.

DRY BOX OR TOP-MOUNTED SPOOL HOLDER?Finally, regarding filament placement: remember that the Prusa design offers an adjustable filament spool holder for the top. I'm not using that personally, because instead I will be using my existing, excellent filament dry box design, which is another remix I plan to post soon. If you want the adjustable filament spool holder for the top, just head over to the original Prusa design and grab it.

Oh, and as promised...

HOW I PRINT MUCH QUICKER WITH STOCK HARDWAREHere are the two videos that give details on how I print much faster with stock hardware (changes to slicer settings only):

"BIG nozzles - HOW they (can) make your 3D prints STRONGER" by CNC Kitchen Nov 23, 2019 https://www.youtube.com/watch?v=QfASQ8VgAbk&t=670s

"Print FASTER: Tuned Profiles or Drilled Nozzles?" by Thomas Sanladerer Sep 25, 2020 https://www.youtube.com/watch?v=6fPq8vUS38Y

Edits LogAdded a Zip file of all the "single piece" STL files (only needed if you have to reprint something). Naturally, the Zip is named "STL single pieces (only if you need to reprint something).zip" :-)