Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:4403017.

There are newer versions of this thing here:

Ender 3 & CR10 version https://www.thingiverse.com/thing:4943125 Ender 5 version https://www.thingiverse.com/thing:4945681

Background

Although I really enjoy my Hydra Fan Duct design both my Ender 3 Pros have exclusively 4010 ducts with a Bowden system. I therefore thought they may be better suited with a more Compact Lightweight system that provides some expansion\versatility but keeps the base unit to a reasonable minimum. I have since expanded the concept to use 5015 fans and the ability to mount with the 5015 fans to an Ender 5 (the X axis timing belt needs to be replaced to achieve this on the Ender 5).

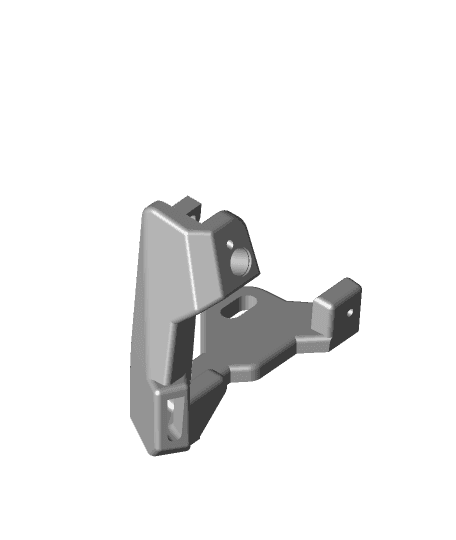

Manta Compact Duct System

There is a newer version of this thing here: https://www.thingiverse.com/thing:4943125

The Manta compact duct system is based on a 3010 Hot End Fan(similar to the V6). For this reason it also incorporated standard and Volcano versions of the V6.

The 3010 fan being smaller can be a little more noisy ( I have used reasonable quality ball bearing fans rather than hydrualic and therefore are quite good) but due to its size it sits above the heater block much closer to the heat sink and therefore hopefully is much more efficient than the stock 4010 cooling fan again like the V6.

There are 2 sets of work in progress BL Touch brackets for a starter. The first includes integral mounting bosses and slotted mounting plates for both the Stock & V6 versions of the 4010 duct base mounts. Secondly I have included a WIP Fixed Universal bracket for the BL Touch which will work with both 4010 & 5015 fans. I have printed prototypes for these but not as yet installed to confirm mount heights. The universal bracket has its own set of Direct Drive standoffs and WM clips which have been adjusted to take into account the additional bracket depth.

The system includes.

1.Stock & V6 base 4010 & 5015 low profile ducts for the CR10 and Ender 3 (Ender 5 5015 ducts only). 2.Tool Change options including Stock Direct Drive, BMG Direct Drive, Dual Gear Direct Drive and standard Bowden. 3.Easy external face height adjustment of fans up to 6mm. 4.Wire Management\cable Tidy options. 5.Clear viewing window of nozzle whilst printing. 6.Includes V6 Volcano ducts for 5015 fans (8.5 mm taller). 7.I have uploaded a Duct Base comparison chart to offer some explanation. Just in case this does not get updated please check the thing files themselves for available options.

Installation

1.I have also uploaded some basic installation guides for both the stock & the V6 versions. The guides only cover the basics to get started with the system. Please comment or message if you require further information. There are also uploaded images for BL Touch offsets and nozzle dimensions off the build plate.I have also uploaded a step file of the full system if anyone wants to create any derivatives. 2.You will need various M3 hex bolts ranging from 6mm long to 16 mm and some M3 Brass thermal inserts. The quantities of each will vary depending on which parts of the system you adopt. The inserts I used were: https://www.amazon.co.uk/gp/product/B01GO4O0OW/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 3.The 3010 fans used: https://www.amazon.co.uk/gp/product/B07DB59XP8/ref=ppx_yo_dt_b_asin_title_o04_s00?ie=UTF8&psc=1 4.M3 Bolt set Used: https://www.amazon.co.uk/gp/product/B07JNDYL2B/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 5.All parts marked WIP in front of the file name have been printed but not yet installed. I did have one previous comment that the BMG tool head flexed a little due to the small web, this can easily be increased but may interfere with the BMG access hatch. 6.Being a compact system some areas are quite tight therefore greater patience is required with the wire management to reduce cable breakage. 7.For the Ender 5 5015 versions to work you need to replace the X axis drive belt, connecting it with cable ties rather than the exiting cleats to provide clearance for the ducts. I have uploaded an image\explanation of how I achieved this on my Ender 5. 8.I have printed and tested prototype parts for 5 printers including 4010, 5015, stock, V6 and V6 volcano versions with both Bowden & Direct Drive tool heads. Clearly with so many variations I may have missed something on the ones I have not tested but hopefully not anything major. 9.I have undertaken some basic CFD testing with Simscale and have uploaded some images of the results which I have used to optimise the duct designs. 10.When using a Volcano Heater Block you will have to rotate the block by approximately 5 to 10 degrees to clear the lower pulley mount on the mounting plate. I would suggest keeping the heater cables to the existing side of the block also. 11.IF using the Creality dual gear extruder you will need to replace the tension bolt with a bolt with a traditional hexagonal head and use a spanner sidewise to tension in this orientation. 12.The Direct Drive Duct Bases can also be used for a Bowden set up has the RH fixings for the WM Upstand are identical to both base types.

Printing 1.The majority of the parts print without support (the base ducts print upside down) except for the rear duct mounts which unfortunately require some support. I have included some sacrificial layers in some of the holes in the mounts which will need cleaning in addition to the supports. 2.The WM Upstand and Clips will require either a very slow print speed or a raft due to their small footprint. 3.It is suggested that parts be printed in the orientation uploaded. 4.I have included 2 sizes of Wire Management clip but there is also a rib on the inside of each clip which can be shaved if further cable space is required. 5.The ducts print without support on their backs but there is an integral support within the 4010 ducts which will require cleaning off immediately below the lower front fixing boss which needs cleaning off prior to insertion of the 4010 fan (see uploaded image of duct). 6.Printed with White, Blue, Red & Black Amazon Basics PETG on an Ender 3 Pro, Ender 5 and my Hypercube. 7.I have included 2 sizes of clamp for the V6 versions has the tolerance can differ to different filaments and printers. They are very small parts so will not take long to create a test print of each. 8.All the base ducts print upside down do make sure your build plate is clean to provide a neat finish. 9.All parts printed with Amazon Basics PETG with 3 perimeters, 30% infill @30mms.

Update:05\0221

Links to High res images of BLTouch offsets https://www.dropbox.com/s/oxlwlosd6ghoup2/BLT%20Build%20Plate%20Offsets%20V2%204010.jpg?dl=0 https://www.dropbox.com/s/1ne2kw3ogqz9nzx/BLT%20V2%20Bracket%20Offsets.jpg?dl=0

Update:29\09\20 Uploaded Step File for the 5015 V2 Ducts with larger duct apertures.

Update 08\08\20 Uploaded V2 version 5015 ducts for both the V6 Standard & Stock Versions. The V2 versions have a slightly larger duct aperture to allow more air volume with the 5015 fans.

Update 12\07\20 Uploaded a Stock Only BL Touch Bracket which is 3mm shorter than the universal bracket on a members request. This will not fit the V6 versions. Please remember to adjust the offset in your firmware by 3mm if using this part. WIP BLT Bowden+M3 Sockets V3_Stock Only

Update 01\06\20: Uploaded WIP Universal BL Touch Bracket for both 4010 7 5015 Fans. The Direct Drive Standoffs will require some support. Printed prototypes but not yet installed working BL Touch Height to be confirmed. Also uploaded a revised WM Upstand V3 which a more material around the base to provide a better finish\retention when inserting the M3 thermal insert.