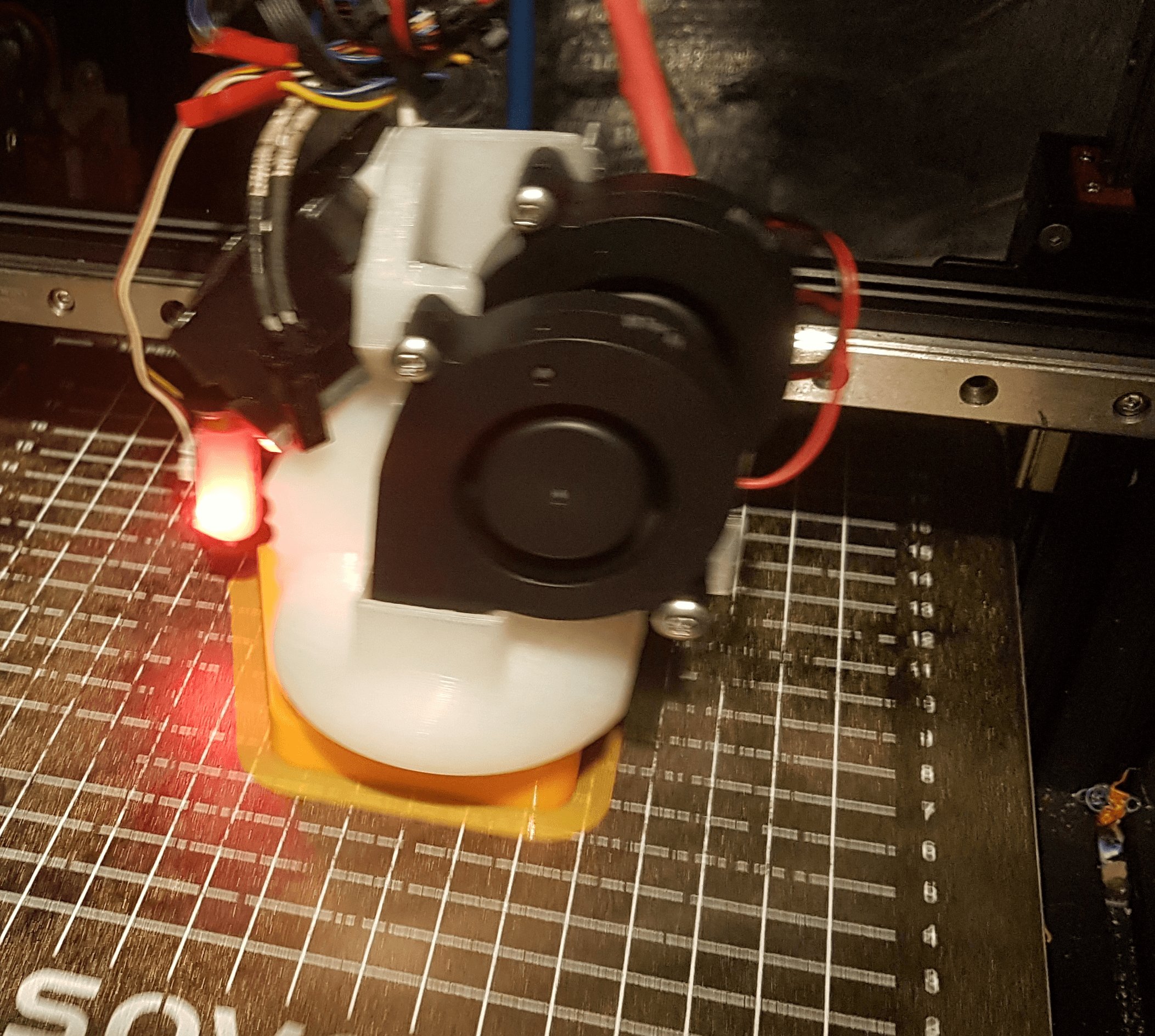

Microswiss NG Dual 5015 blower shroud

IMPORTANT: Take care when slicing. Support blockers should be placed on the internal cavity of the part blower all the way from the top of the duct to the print plate. I got the best results using tree supports for the other exposed area's.

I have heen using this for a while now and am able to mainain 80 degree overhangs with no support using this setup running the fan at 45-65%.

I made mine out of Nylon and it takes the heat radiated from a 110 degree heated bed no problem without sagging.

You will need 4 M4x20mm button head screws and 4 M4 nuts to secure the fans to their mounts.

Also required is a M3 10mm button head screw and nut for the right side screw mount to the backplate. Screw it on from the opposite side of the backplate, mount the shroud and use a M3 nut to secure the right side of the shroud. (see pic)

The left side screw goes in as per the original shroud.

i printed the version i am using now using .2mm layer height and 40% gyroid infill, but when i was running test prints during the iteration process of designing this .32 layer height and 25% infill came out just fine.

Might pay to print this a bit slower than normal, you know your printer better than me, but i got best results when slowing it down.