Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:4672175.

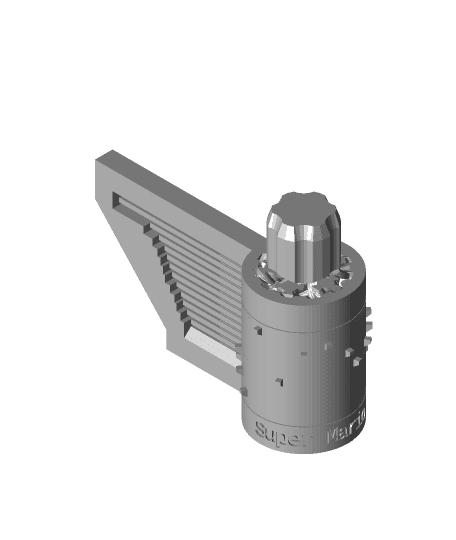

Parametrized Music Box - Print in Placealso on MyMinifactory and GitHub Musical calculations remixed from Parametric Music Box See it in action and in closer

I'd strongly suggest ABS or something with good fatigue resistance for this one. Not only does PLA not have a good "plink", the fingers won't survive long from being repeatedly plucked. (see below)

Print at 0.2mm layer height (check in preview that the 1-layer gaps are preserved when slicing). Somewhat sensitive to bed level and overextrusion so dial your printer in with a tolerance gauge.

Don't get your hopes up, I was somewhat disappointed by the acoustic properties of PLA but it's a nice little toy none the less.

Post-printing, free up the gears by turning the knob clockwise (due to the direction of the herringbone gears - less likely to break). I use a 5/16" socket to get a bit more leverage on the knob. The key is controlled force and repetitive small motions until it breaks free.

Next use a straight-edged razor to delaminate the two ring gears. Just wedge it in enough to hear a small crack all the way around. Turning the gears will do the rest.

Some of the "fingers" will free up on their own, the others can be helped gently with the razor. A sliver of an aluminium can can be a useful scraper to get inbetween.

The version with the 1-layer gap between fingers doesn't sound too hot (the fingers rub on each other) but requires no support. I made another with a 3-layer gap which can use a layer of support material (high overhang angle so it doesn't mess with the gears). I was tempted to build support into the model but decided this was the job of the slicer. Only the finger tips need to be supported as the rest can bridge, so strategic use of support blockers will make it easier to remove (40mm cube -25mm in x).

This model is really just a gimmick, but I can see something like this being incorporated into a design which provides a high RPM input and a sound board. Something like a little wind turbine. Otherwise, if it had a bit more weight, you could hold it by the knob and twirl it.

UPDATE: The first critical design flaw has surfaced (apart from needing a little post-processing finesse). The fingers will suffer fatigue failure after a few hours of continuous use. I suspect this may be a hard limitation of PLA. Alternatives may exist by incorporating other materials eg. bamboo inserts or altering the design to use rigid moving parts such as little hammers sprung by an elastic band. Angling the fingers might also help by not plucking them so aggressively. The "low" version has been dropped down an octave - longer fingers don't bend so much, which should increase longevity.