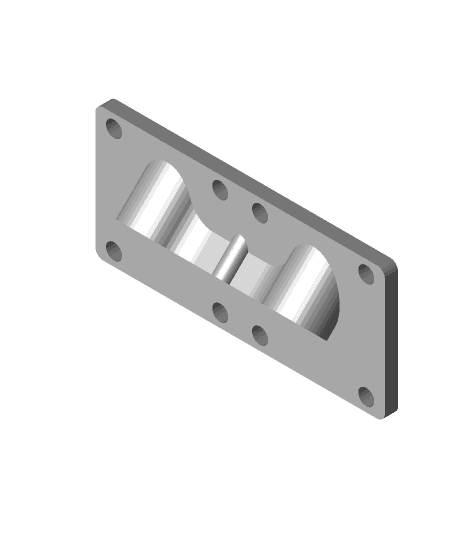

Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:2037034.

This is my first attempt at building a 3D Printer, which has been a learning experience. I set out a bit gung ho as I do without thoroughly researching what is out there in the thriving DIY community but have learned much in the process. I was attracted to the Deltabot design due to its symmetry and mechanical simplicity. A light weight, fast print head and a stationary build platform. Fortunately the more complicated software side has already been taken care of with many options available.

Some of the things I'd like to improve for my second attempt would include:

- Smaller diameter linear rod. 20mm is clearly overkill, adds to overall weight and cost and consumes build volume for a given footprint. I'll be trying 8mm diameter linear rod next time.

- Lower the build plate. Currently the bottom 60% of the linear rod is unused as the carriages don't go down that far. I could make the push rods shorter, but this has effects on maximum speed possible. Having the build plate at the bottom of the rod is not cost effective in this regard - we could get away with half length linear rods and lead screws mounted higher.

- As above, we may need to relocate stepper motors to the top to accommodate shorter lead screws required.

To follow on from this design, I would also like to attempt a CoreXY build, as this has similar advantages to the Delta design in respect to stationary stepper motors and lightweight print head but a much bigger build volume compared to the overall dimensions, particularly height.

note: The integrated carriages are not tested.