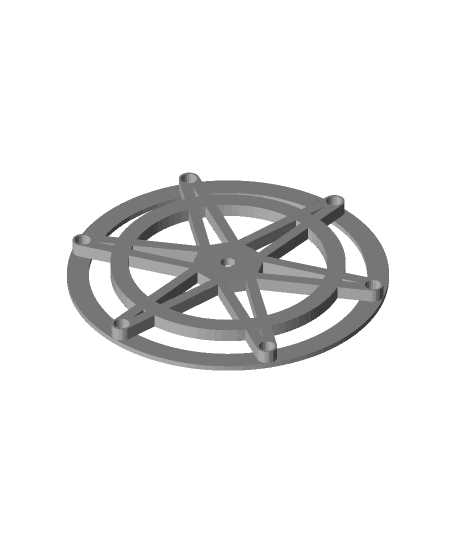

#3DPNSpeakerCover This is a speaker cover designed to use the speaker to rotate vibration powered disks ( it looks real cool). here is the assembly for reference https://thangs.com/smsandoval2019/assembly-mk2-moving-speaker-comp-v4stl-14541

EDIT: Due to my inability to edit this page and upload new revisions of my design keeping things organized has proven difficult on thangs. Some of the tolerances are not as tuned as id like them to be because i cant find a way to remove or add new STLs to this page. I also dont want to risk disqualifying myself from the contest by uploading revised versions that might be to similar to already submitted models.This is a little frustrating becuase i think this idea is really cool. However i am going to make one more part that i will link (https://thangs.com/smsandoval2019/stage-one-only-central-corestl-14537) that will be a core piece that is a little shorter in case the upper stage does not have appropriate tolerances. Note that this design still works if play and friction can be reduced enough but it is not as polished as i would like.

This design is very complex and would greatly benefit from the abilities of 3D printing. the main driving concept in this model is the small feet like features on rings 1 and 2. much like Vibrots or the kids toy Hexbugs these feet act like springs that use vibrations to produce motion in the rings.

in my tests so far i have been able to get them to spin pretty fast but reducing friction in the system and decreasing play is the key to getting this to work. for this reasons ive found that printing the parts out of different materials works best. i only have access to an ender 3 so my quality is very limited. (hopefully Joel's accesses to professional machines will avoid a lot of the stringing issues i had)

here is a list of my thoughts of what materials work best:

Main base, spacers, stage 2 base, washer need to be rigid to transfer the vibrations to the rings. for this reason I think something like ABS or PLA would be best. I'm not to familiar with resin but the smoother finish would help reduce friction for the feet to bounce so this might be the preferred method.

the two rings are a bit tricky. the feet need to be relatively springy but the rings need to be rigid so they don't flex and absorb vibrations. something like PETG should work. the feet do love to make strings though so maybe a form of springy resin would be best for these. perhaps multi-material would also work like using abs for the ring and semi-flex for the feet.

the assembly is currently held together with an M5 bolt which threads into the central core with help from the washer.

this thing looks pretty cool when it turns. I'm still improving it and am open to any suggestions. this iteration only uses a one bolt but i do think that the design would benefit the use of bearings and steel rods to reduce friction. although I'm not sure if something with that much hardware would still qualify for the contest

i am working on getting a video together about proof of concept and an assembly animation, which i will link soon.

lastly i will continue to upload cosmetically different forms of the ring but will all be interchangeable to make a completely unique assembly