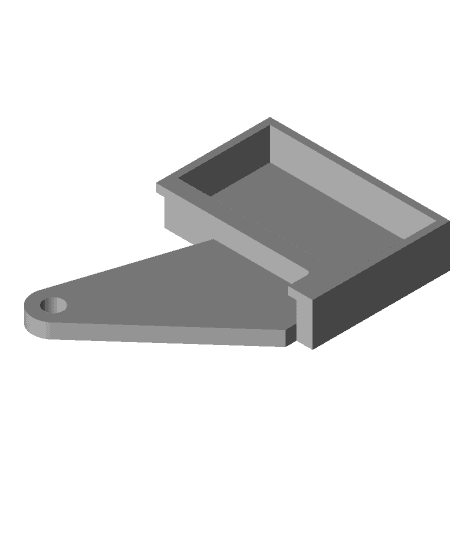

This is an attachment for the bed of the Ender 3 v1

It gets mounted on the right side of the bed and it is hold in place via the screw and spring of the bed levelling knob.

In order to use this mod you will need to cut a sponge, a dish washing sponge will do or a piece of steel wool. I am using a double side sponge in order to get max cleaning results.

You can use the "Ender3 nozzle wiper sponge cutter" object to cut a sponge of the correct size. simply cut the sponge using the model as refence. then stuff the sponge inside and trim the sponge so it sits flushed with the edge.

Now for the cleaning routine, you have 2 choices.

1- modify marlin firmware in order to allow the print head to move outside the printing area

2 - use the command M211 S0/S1 to disable the firmware end-stops and allow the printhead outside the legal boundaries. I went this way. But be very careful in doing that as if you do not home the printer first, you will slam the X and Y axis into the physical limit of the printer and risk of damaging the machine it self .

for the GCODE set up; you can create a custom file and "print it " in order to run the cleaning routine or you can put it as start GCODE in your slicer and run it before every print, this is up to you.

start GCODE for CURA:

; Ender 3 Custom Start G-code G92 E0 ; Reset Extruder G28 R5 ; Home all axes

M211 S0 ; disable endstops G1 Z15 F200 ; raise Z so we don't scratch up the bed G1 X234 Y6 F2000 ; go to first point

G1 Z1 F200 ; Dip the nozzle in the sponge

G1 X247 Y6 F500 ; start cleaning M117 BEGINNING CLEANING PROCEDURE ; message

G1 X247 Y13 F500 ; cleaning..... G1 X234 Y13 F500 ; cleaning..... G1 X234 Y20 F500 ; cleaning..... G1 X247 Y20 F500 ; cleaning..... G1 X247 Y27 F500 ; cleaning..... G1 X234 Y27 F500 ; cleaning..... G1 X234 Y34 F500 ; cleaning..... G1 X241.5 Y34 F500 ; cleaning..... G1 X241.5 Y6 F500 ; cleaning.....

G1 Z15 F200 ; Raise nozzle out of the sponge G1 X230 Y6 F500 G1 X100 Y6 F500 ; return to first point M117 END CLEANING ; message M117 READY ; message M211 S1 ; enable endstops

G92 E0 ; Reset Extruder G1 Z2.0 F3000 ; Move Z Axis up little to prevent scratching of Heat Bed

the G1 Z1 F200 movement define how much to dip the nozzle into the sponge. this is up to you . 1mm works fine me.

I provide this mod as-is and I do not offer any warranty. You are tasked to perform your own testing and decide if this mod is safe and suitable for your own use case scenario.

Also, I am using a dish sponge to perform the cleaning and the sponge is made out of plastic. You must run the cleaning procedure when the nozzle is cold in order to prevent any risk of fire to occur.

if you want to run the cleaning procedure when the nozzle is hot, use a piece of steel wool