Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:3908192.

I got back into building balsa R/C and FF models in 2017 after having been out of the hobby for 15 years. While I was perfectly ok with building planes the old-school way, pinning parts to a soft flat board, I figured out quickly that magnetic building boards and 3D printing go together like PB&J. I started out with Marco_D's excellent fixtures, but through several builds, I've gradually designed more of my own fixtures as I've seen opportunities to do so.

All my fixtures use the same 20x10x4mm rare earth magnets as many of Marco_D's. For attaching the magnets, I have included holes in the parts that a 4-40 flathead screw will thread into without requiring tapping - M3 screws may also work but I haven't tried it. The slotted triangles, bridge beam, and press arms take #10 or M5 screws. The press arm holes will need to be tapped in either case.

I have included a ZIP file of the source parts in Solidworks 2016 format.

Pictures should give some idea of how fixtures are used, but here are a few notes on the function of each:

- tapped holddown: Remix of Marco_D's, holds down parts with thicknesses of 1/16", 1/8", 3/16", and 1/4".

- ext_hold_down: Same as above, but with extended tapered fingers for reaching into corners better.

- tall 4-way holddown: same as tapped holddown but for heights of 3/8", 1/2", 5/8", and 3/4".

- step triangle: Remix of Marco_D's with slot changed to use rare earth magnet.

- large tri and med tri: use by themselves to hold parts square to board, or in conjunction with bridge beam or press arm as required.

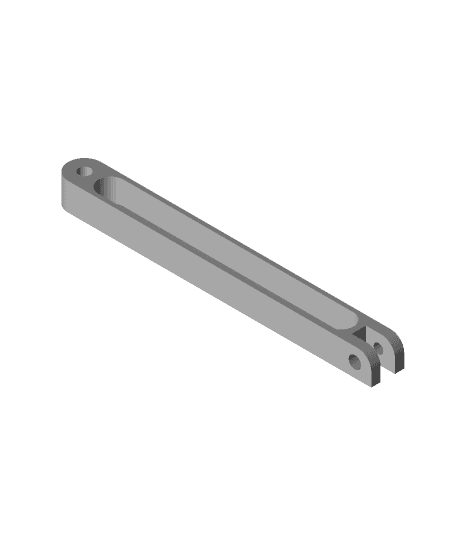

- 25/50/75/100mm press arm: attach to slotted triangle and and adjust vertical screw to hold large parts down.

- bridge beam: attach to 2 slotted triangles to support parts in midair.

- magnetic former jig & former jig holddown (WARNING - UNTESTED): I designed this for an old-timer design with a horizontal crutch and elliptical formers, which requires the whole fuselage be framed up in midair. The idea is to set the crutch on the top surface and use the holddowns like hooks, while using a couple more holddowns as pressing fingers to hold the former to the face in the correct position. The CAD image might explain it more clearly. Very specialized use case, so you probably won't ever need it.