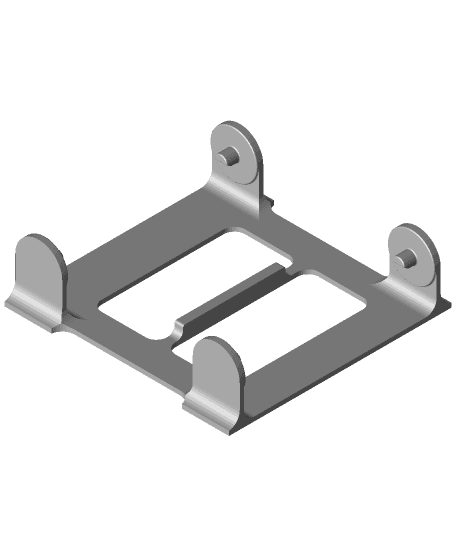

We frequently use 3d printers and forget to take care of the filaments we use. As filaments are generally made up of biodegradable material (PLA, ABS) and can easily absorb the moisture present there. It may cause the filament to swell up and get stuck inside the hot extruder. Also when atomic dust particles go along with filament inside a hot extruder the layers which are getting 3d printed one above another may get air gaps and there is an extreme possibility of cracks on our 3d printed part. We found out a solution to this problem. The filament spool holding parts in.STL format attached in this upload is assembled and kept inside an air-tight box. A tube is taken out from this box using pneumatic connectors. Now you can see the filament spool rolling on rollers inside the air-tight box when 3d printer extruder is moving over heat bed to get uniform and nice prints. Youtube link: https://www.youtube.com/watch?v=hSnl8tHsUZA